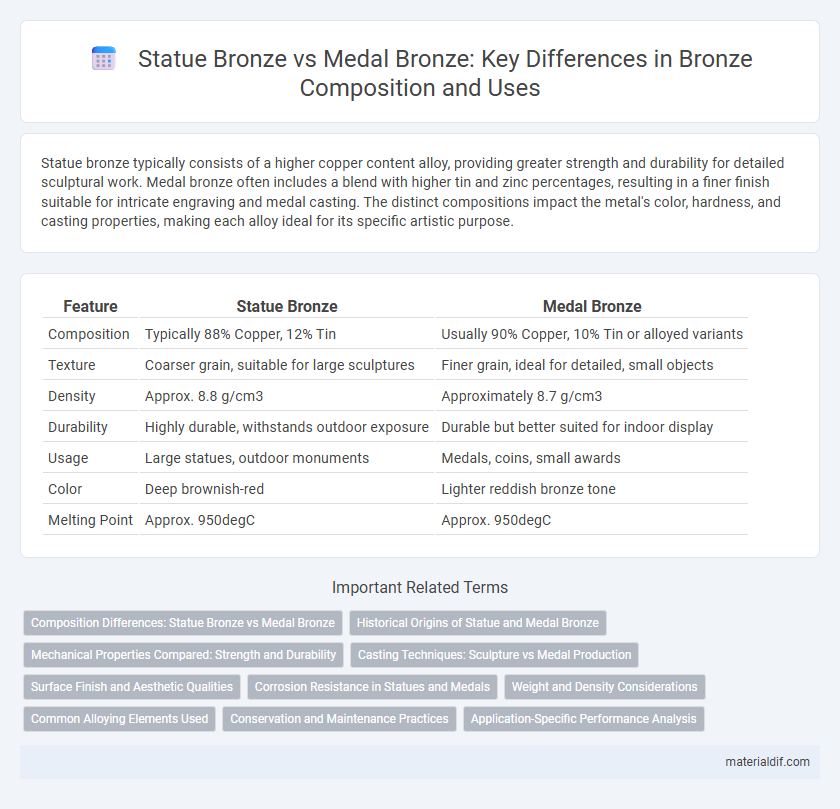

Statue bronze typically consists of a higher copper content alloy, providing greater strength and durability for detailed sculptural work. Medal bronze often includes a blend with higher tin and zinc percentages, resulting in a finer finish suitable for intricate engraving and medal casting. The distinct compositions impact the metal's color, hardness, and casting properties, making each alloy ideal for its specific artistic purpose.

Table of Comparison

| Feature | Statue Bronze | Medal Bronze |

|---|---|---|

| Composition | Typically 88% Copper, 12% Tin | Usually 90% Copper, 10% Tin or alloyed variants |

| Texture | Coarser grain, suitable for large sculptures | Finer grain, ideal for detailed, small objects |

| Density | Approx. 8.8 g/cm3 | Approximately 8.7 g/cm3 |

| Durability | Highly durable, withstands outdoor exposure | Durable but better suited for indoor display |

| Usage | Large statues, outdoor monuments | Medals, coins, small awards |

| Color | Deep brownish-red | Lighter reddish bronze tone |

| Melting Point | Approx. 950degC | Approx. 950degC |

Composition Differences: Statue Bronze vs Medal Bronze

Statue bronze typically consists of a higher percentage of copper combined with tin and small amounts of zinc, which enhances durability and creates a desirable patina for large sculptures. Medal bronze, on the other hand, often features a different alloy composition with increased zinc and sometimes lead to improve malleability and detail retention for casting smaller, intricate objects. These compositional differences reflect the distinct functional and aesthetic requirements of statues versus medals.

Historical Origins of Statue and Medal Bronze

Statue bronze originated from ancient civilizations like Greece and Rome, where artisans developed high-tin bronze alloys to create large, durable sculptures reflecting cultural and religious significance. Medal bronze, emerging in the Renaissance, was crafted with lower tin content and higher copper concentration to facilitate finer details and smoother surfaces for small, commemorative medals. Both forms utilized differing alloy compositions tailored to their specific artistic and functional requirements rooted in distinct historical contexts.

Mechanical Properties Compared: Strength and Durability

Statue bronze typically features a higher copper and tin content, resulting in superior tensile strength and enhanced durability compared to medal bronze, which contains more zinc for increased malleability but reduced mechanical robustness. The increased strength of statue bronze allows it to withstand environmental stress and corrosion over prolonged outdoor exposure. Medal bronze's lower mechanical strength makes it ideal for detailed casting but less suitable for structural or large-scale applications.

Casting Techniques: Sculpture vs Medal Production

Statue bronze casting typically employs the lost-wax method, allowing for intricate details and larger-scale sculptures with complex textures. Medal bronze production often utilizes die striking or sand casting, optimizing precision and uniformity for smaller, flat designs suited to mass production. The differing casting techniques reflect the distinct functional and artistic requirements of statues versus medals within bronze art.

Surface Finish and Aesthetic Qualities

Statue bronze typically features a smooth, polished surface finish with rich patinas that enhance its depth and visual appeal, while medal bronze often has a finer, more detailed surface texture to capture intricate designs and inscriptions. The aesthetic qualities of statue bronze emphasize bold, three-dimensional forms and dramatic light reflections, contrasting with medal bronze's precise relief work and subtle tonal variations. These differences in surface treatment and artistic focus distinguish the tactile and visual experiences of statue bronze versus medal bronze artworks.

Corrosion Resistance in Statues and Medals

Statue bronze, typically an alloy of copper with tin and small amounts of zinc or lead, offers superior corrosion resistance due to its composition and thickness, making it ideal for outdoor sculptures exposed to weather and pollutants. Medal bronze, often a thinner alloy with higher copper content, provides less durability against corrosion, which can lead to tarnishing and surface degradation over time. The metallurgical differences affect longevity, with statue bronze maintaining aesthetic and structural integrity in harsh environments far better than medal bronze.

Weight and Density Considerations

Statue bronze typically has a higher density ranging from 7.5 to 8.9 g/cm3, leading to significantly greater weight compared to medal bronze, which generally has a density around 7.4 to 8.0 g/cm3. The increased mass of statue bronze enhances durability and stability, essential for larger sculptures exposed to environmental elements. Weight considerations are crucial in statue bronze casting to ensure structural integrity without compromising artistic detail.

Common Alloying Elements Used

Statue bronze typically contains a higher percentage of copper (around 88-95%), combined with tin (5-12%) as the primary alloying element to enhance durability and casting detail. Medal bronze has a similar base but often incorporates small amounts of zinc and lead to improve malleability and finish for intricate designs. Both types of bronze rely on copper and tin as fundamental components, with variations in secondary elements tailored to their specific artistic and functional requirements.

Conservation and Maintenance Practices

Statue bronze, typically composed of a higher copper content with added tin and zinc, requires regular patina preservation and protective waxing to prevent corrosion from outdoor elements. Medal bronze, often a finer alloy with smoother surfaces, necessitates careful cleaning with non-abrasive materials to maintain detailed relief and avoid oxidation. Both forms benefit from controlled humidity and avoidance of harsh chemicals to ensure long-term durability and aesthetic integrity.

Application-Specific Performance Analysis

Statue bronze typically exhibits higher tensile strength and corrosion resistance, making it ideal for large-scale outdoor sculptures exposed to varying environmental conditions. Medal bronze, often alloyed with higher concentrations of tin and zinc, offers superior surface hardness and fine detail retention, essential for intricate medal artistry and longevity under frequent handling. Application-specific performance analysis reveals that statue bronze prioritizes durability and structural integrity, while medal bronze emphasizes aesthetic precision and wear resistance.

Statue Bronze vs Medal Bronze Infographic

materialdif.com

materialdif.com