Tin bronze offers excellent corrosion resistance and superior machinability, making it ideal for bearings and marine hardware. Nickel bronze provides enhanced strength and wear resistance, often favored in heavy-duty applications like industrial gears and valve components. Choosing between the two depends on balancing cost-effectiveness and performance requirements in specific environments.

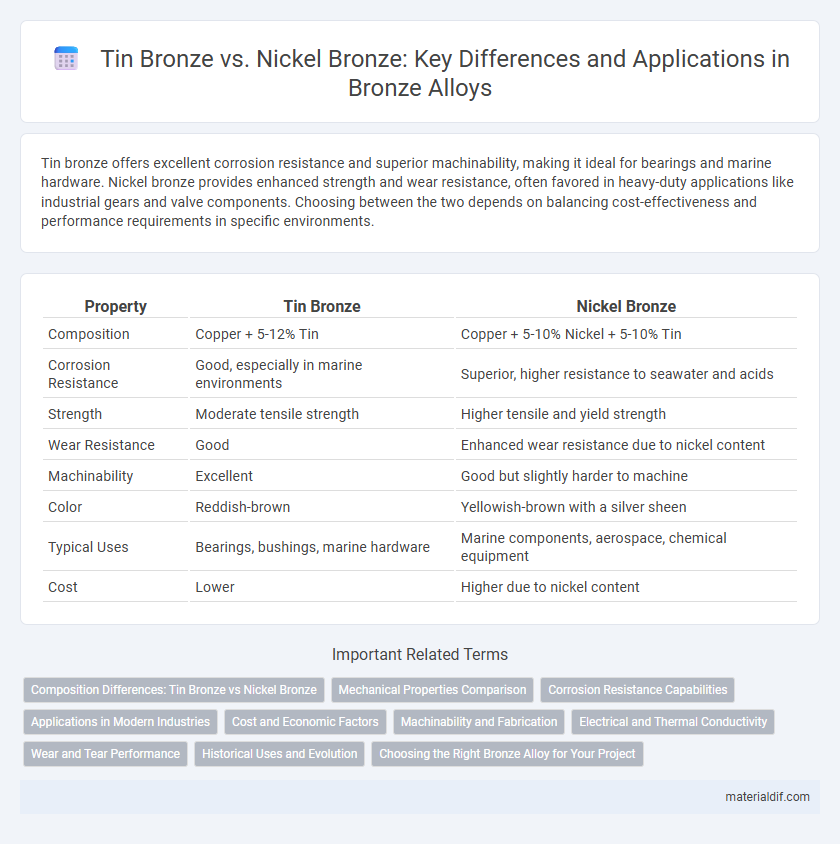

Table of Comparison

| Property | Tin Bronze | Nickel Bronze |

|---|---|---|

| Composition | Copper + 5-12% Tin | Copper + 5-10% Nickel + 5-10% Tin |

| Corrosion Resistance | Good, especially in marine environments | Superior, higher resistance to seawater and acids |

| Strength | Moderate tensile strength | Higher tensile and yield strength |

| Wear Resistance | Good | Enhanced wear resistance due to nickel content |

| Machinability | Excellent | Good but slightly harder to machine |

| Color | Reddish-brown | Yellowish-brown with a silver sheen |

| Typical Uses | Bearings, bushings, marine hardware | Marine components, aerospace, chemical equipment |

| Cost | Lower | Higher due to nickel content |

Composition Differences: Tin Bronze vs Nickel Bronze

Tin bronze primarily consists of copper alloyed with 5-10% tin, enhancing its strength and corrosion resistance. Nickel bronze, on the other hand, includes copper mixed with 5-30% nickel along with smaller amounts of iron and manganese, providing superior hardness and improved wear resistance. The key composition difference lies in tin's role in tin bronze for improved casting and machinability, whereas nickel in nickel bronze significantly increases toughness and resistance to marine corrosion.

Mechanical Properties Comparison

Tin bronze typically exhibits higher tensile strength and better wear resistance due to its tin content, making it suitable for heavy-duty applications. Nickel bronze, on the other hand, offers superior corrosion resistance and enhanced toughness, attributed to the presence of nickel, which improves impact strength. Both alloys show excellent mechanical properties, but the choice depends on specific requirements like strength, durability, and environmental conditions.

Corrosion Resistance Capabilities

Tin bronze exhibits excellent corrosion resistance in marine and industrial environments due to the protective oxide layer formed by tin content, making it ideal for applications exposed to saltwater and acidic conditions. Nickel bronze enhances corrosion resistance further, especially against alkaline and acidic environments, thanks to the addition of nickel which improves resistance to pitting and crevice corrosion. Both alloys provide superior durability in corrosive settings, but nickel bronze offers an edge in chemical resistance and longevity in harsher conditions.

Applications in Modern Industries

Tin bronze is widely used in marine hardware, bearings, and electrical connectors due to its excellent corrosion resistance and machinability, making it ideal for marine and electrical industries. Nickel bronze, enhanced with nickel, offers superior strength and wear resistance, making it suitable for heavy-duty applications such as aerospace components, automotive parts, and industrial machinery. Both alloys provide reliable performance under stress, with nickel bronze preferred in environments demanding higher durability and tin bronze favored for cost-effective corrosion resistance.

Cost and Economic Factors

Tin bronze generally offers lower material costs compared to nickel bronze due to the abundance and lower price of tin versus nickel. Nickel bronze, while more expensive, provides superior corrosion resistance and mechanical strength, which can justify higher initial costs in applications demanding durability. Economic factors such as availability of raw materials and long-term maintenance expenses influence the selection between these two bronze alloys in industrial applications.

Machinability and Fabrication

Tin bronze offers excellent machinability with a fine-grained structure that reduces tool wear and allows for precise fabrication, making it ideal for detailed components. Nickel bronze, while harder and more corrosion-resistant, poses greater challenges during machining due to its toughness, often requiring specialized tools and slower cutting speeds. Fabrication of tin bronze is generally easier and more cost-effective, whereas nickel bronze demands advanced techniques to maintain structural integrity during forming and finishing.

Electrical and Thermal Conductivity

Tin bronze exhibits electrical conductivity around 15% IACS and thermal conductivity approximately 60 W/m*K, making it suitable for moderate conductivity applications. Nickel bronze, with lower electrical conductivity near 5% IACS and thermal conductivity about 30 W/m*K, excels in corrosion resistance but compromises on conductivity metrics. Selecting between tin bronze and nickel bronze depends on balancing conductivity performance with mechanical strength and environmental durability requirements.

Wear and Tear Performance

Tin bronze exhibits superior wear resistance due to its hardness and ability to form a stable oxide layer that reduces friction in sliding applications. Nickel bronze offers enhanced toughness and corrosion resistance, which contributes to longer service life under dynamic stress and harsh environments. In applications requiring prolonged mechanical wear and exposure to corrosive elements, nickel bronze generally outperforms tin bronze by maintaining structural integrity and resisting surface degradation more effectively.

Historical Uses and Evolution

Tin bronze, historically prominent since the Bronze Age, revolutionized early toolmaking and weaponry due to its superior hardness and corrosion resistance compared to pure copper. Nickel bronze emerged more recently, gaining traction during the 19th and 20th centuries for its enhanced strength, durability, and resistance to marine corrosion, making it ideal for industrial and marine applications. Evolution from tin bronze to nickel bronze reflects technological advancements in alloying techniques, adapting bronze's applications from ancient artifacts to modern engineering solutions.

Choosing the Right Bronze Alloy for Your Project

Tin bronze offers excellent corrosion resistance and superior strength, making it ideal for marine and industrial applications where durability is critical. Nickel bronze provides enhanced wear resistance and a smooth finish, suitable for decorative elements and components exposed to friction. Selecting the right bronze alloy depends on balancing mechanical properties, environmental exposure, and aesthetic requirements of your project.

Tin Bronze vs Nickel Bronze Infographic

materialdif.com

materialdif.com