Bronze machining offers precise shaping and detailing by removing material to achieve tight tolerances, making it ideal for components requiring intricate designs. Bronze welding involves joining bronze parts through controlled heat application, preserving material strength and integrity in repairs or fabrications. Choosing between machining and welding depends on project requirements, with machining preferred for accuracy and welding favored for assembly or restoration tasks.

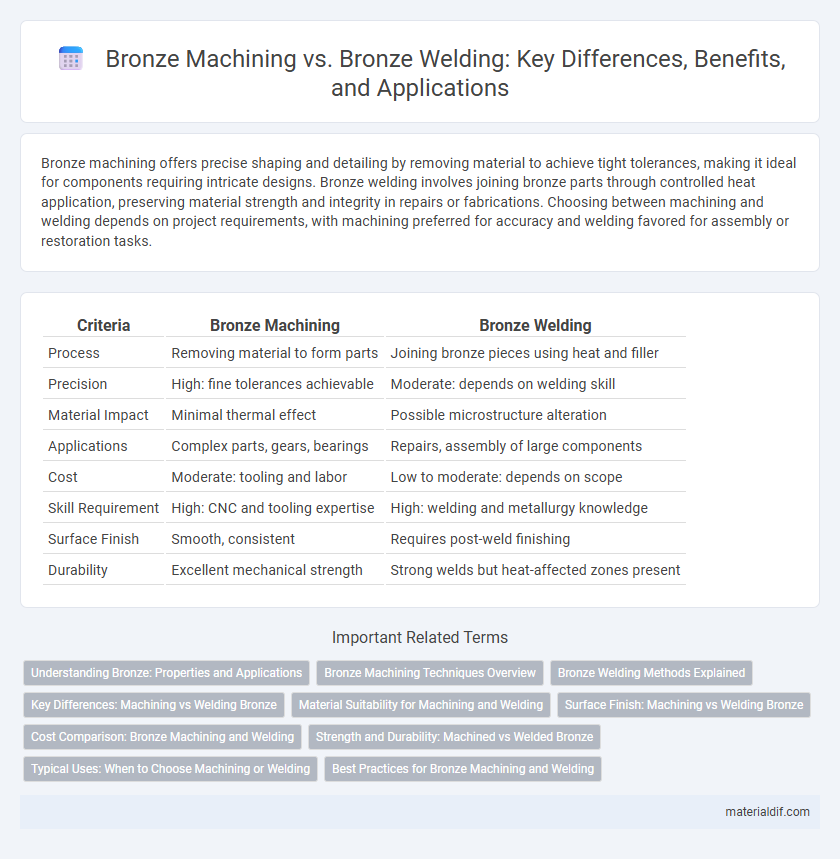

Table of Comparison

| Criteria | Bronze Machining | Bronze Welding |

|---|---|---|

| Process | Removing material to form parts | Joining bronze pieces using heat and filler |

| Precision | High: fine tolerances achievable | Moderate: depends on welding skill |

| Material Impact | Minimal thermal effect | Possible microstructure alteration |

| Applications | Complex parts, gears, bearings | Repairs, assembly of large components |

| Cost | Moderate: tooling and labor | Low to moderate: depends on scope |

| Skill Requirement | High: CNC and tooling expertise | High: welding and metallurgy knowledge |

| Surface Finish | Smooth, consistent | Requires post-weld finishing |

| Durability | Excellent mechanical strength | Strong welds but heat-affected zones present |

Understanding Bronze: Properties and Applications

Bronze, an alloy primarily composed of copper and tin, is known for its excellent corrosion resistance, high thermal conductivity, and good machinability, making it ideal for precise machining processes. Machining bronze allows for the creation of complex components with tight tolerances commonly used in bearings, bushings, and gears, where strength and durability are critical. Welding bronze can be challenging due to its thermal conductivity and potential for cracking, thus it often requires specialized techniques like TIG welding with compatible filler materials for repair or fabrication in structural applications.

Bronze Machining Techniques Overview

Bronze machining involves precise cutting, drilling, and shaping techniques to produce complex components with high dimensional accuracy. Common machining methods include turning, milling, and grinding, utilizing carbide or diamond-coated cutting tools to handle bronze's excellent thermal conductivity and reduce tool wear. Proper coolant application and controlled feed rates are essential to prevent material deformation and achieve optimal surface finish in bronze machining processes.

Bronze Welding Methods Explained

Bronze welding involves specialized techniques such as brazing, gas welding, and TIG welding, each tailored to accommodate bronze's unique thermal conductivity and melting point. Brazing is the preferred method for joining bronze, using a filler metal with a lower melting temperature to prevent base metal distortion. TIG welding offers precise control for thicker bronze components, ensuring strong, clean welds ideal for structural applications.

Key Differences: Machining vs Welding Bronze

Bronze machining involves precise cutting, shaping, and finishing of bronze components using tools like lathes and mills, resulting in high dimensional accuracy and smooth surface finishes ideal for intricate parts. Bronze welding, on the other hand, requires specialized techniques such as TIG or MIG welding with appropriate filler materials to join bronze pieces, focusing on creating strong, durable joints while managing heat input to prevent distortion or weakening. Machining is preferred for manufacturing complex shapes and fine details, whereas welding is essential for fabricating assemblies or repairing bronze structures.

Material Suitability for Machining and Welding

Bronze exhibits excellent machinability due to its fine grain structure and moderate hardness, making it suitable for precision machining processes like turning and milling. However, welding bronze presents challenges because of its high thermal conductivity and susceptibility to cracking, demanding specialized techniques such as TIG or brazing for effective joining. Selecting between machining and welding depends on the bronze alloy composition, with aluminum bronzes favoring welding, while phosphor and silicon bronzes offer superior machinability.

Surface Finish: Machining vs Welding Bronze

Bronze machining produces a smoother, more precise surface finish due to controlled cutting tools that remove material uniformly. In contrast, bronze welding often results in a rougher surface with potential oxidation and heat-affected zones that require additional finishing. Machined bronze parts typically exhibit superior aesthetic qualities and dimensional accuracy compared to welded components.

Cost Comparison: Bronze Machining and Welding

Bronze machining generally incurs higher initial costs due to specialized cutting tools and slower processing speeds, but offers precise and clean finishes with minimal post-processing. Bronze welding can be more cost-effective for large repairs or fabrications, although it requires skilled operators and potential filler material expenses that vary with alloy composition. Overall, the choice between machining and welding depends on project scale, desired finish quality, and long-term durability considerations in bronze applications.

Strength and Durability: Machined vs Welded Bronze

Machined bronze typically offers superior strength and durability due to its uniform grain structure and absence of heat-affected zones, ensuring consistent mechanical properties throughout the component. Welded bronze, while convenient for joining complex geometries, may exhibit reduced strength near weld seams caused by potential microstructural changes and residual stresses. Choosing machined bronze is ideal for applications demanding high structural integrity and longevity, whereas welded bronze suits designs requiring flexibility in assembly but may necessitate post-weld treatments to enhance durability.

Typical Uses: When to Choose Machining or Welding

Bronze machining is typically chosen for precision components requiring intricate shapes, tight tolerances, and smooth finishes, commonly used in gears, bearings, and marine hardware. Bronze welding is preferred for repairing damaged parts or joining components that must maintain corrosion resistance and strength, often employed in heavy-duty industrial assemblies and large structural frameworks. Selecting machining over welding depends on the desired part complexity and production volume, while welding is ideal for maintenance, modifications, or assemblies needing structural integrity.

Best Practices for Bronze Machining and Welding

Bronze machining requires the use of sharp, high-quality cutting tools and controlled speeds to prevent work hardening and ensure smooth finishes, with emphasis on maintaining proper lubrication to reduce tool wear. Bronze welding involves selecting appropriate filler metals like aluminum-bronze alloys and applying precise preheating and post-weld heat treatment to avoid cracking and distortion. Best practices include thorough material cleaning, using TIG or MIG welding techniques for stronger welds, and performing machining in stable conditions to enhance accuracy and durability.

Bronze Machining vs Bronze Welding Infographic

materialdif.com

materialdif.com