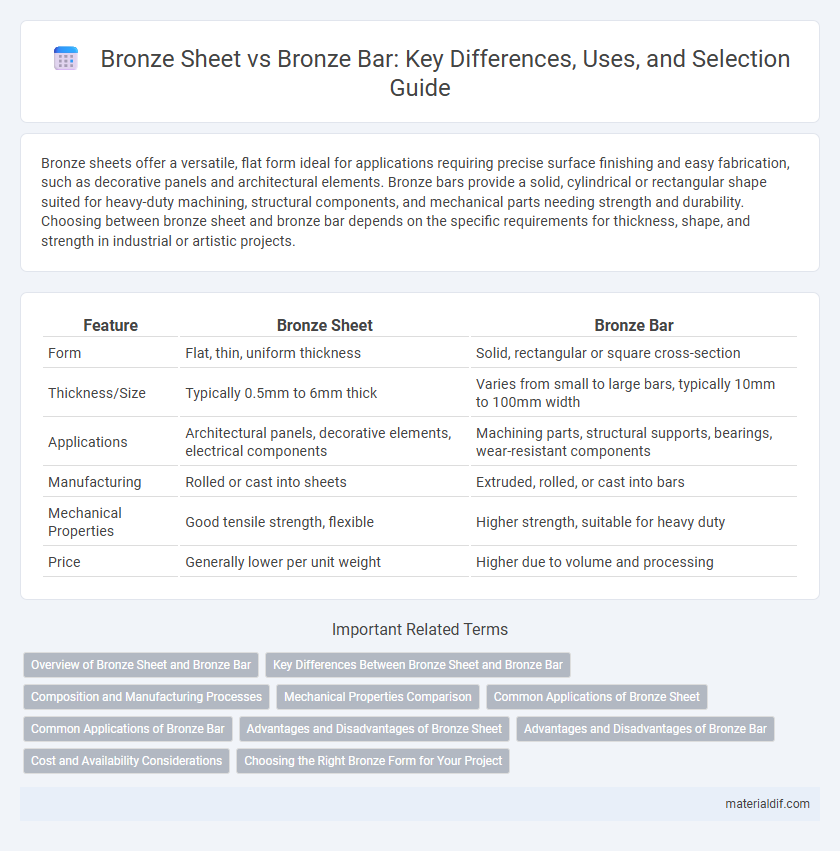

Bronze sheets offer a versatile, flat form ideal for applications requiring precise surface finishing and easy fabrication, such as decorative panels and architectural elements. Bronze bars provide a solid, cylindrical or rectangular shape suited for heavy-duty machining, structural components, and mechanical parts needing strength and durability. Choosing between bronze sheet and bronze bar depends on the specific requirements for thickness, shape, and strength in industrial or artistic projects.

Table of Comparison

| Feature | Bronze Sheet | Bronze Bar |

|---|---|---|

| Form | Flat, thin, uniform thickness | Solid, rectangular or square cross-section |

| Thickness/Size | Typically 0.5mm to 6mm thick | Varies from small to large bars, typically 10mm to 100mm width |

| Applications | Architectural panels, decorative elements, electrical components | Machining parts, structural supports, bearings, wear-resistant components |

| Manufacturing | Rolled or cast into sheets | Extruded, rolled, or cast into bars |

| Mechanical Properties | Good tensile strength, flexible | Higher strength, suitable for heavy duty |

| Price | Generally lower per unit weight | Higher due to volume and processing |

Overview of Bronze Sheet and Bronze Bar

Bronze sheets are thin, flat metal plates typically used in applications requiring precise thickness and easy fabrication, such as decorative panels, musical instruments, and electrical connectors. Bronze bars are solid, thicker pieces offering higher strength and durability, often utilized in mechanical components, shafts, and heavy-duty structural parts. Both forms consist primarily of copper and tin alloys but differ significantly in shape, size, and mechanical applications.

Key Differences Between Bronze Sheet and Bronze Bar

Bronze sheets are thin, flat pieces of bronze metal ideal for applications requiring flexibility, surface detail, and ease of cutting, often used in decorative or architectural projects. Bronze bars, in contrast, are solid, thicker pieces designed for structural strength, machining, and heavy-duty industrial uses such as manufacturing machinery components. The key differences lie in their form factor, with sheets offering versatile surface applications and bars providing robustness for load-bearing purposes.

Composition and Manufacturing Processes

Bronze sheets typically contain a higher proportion of tin, around 12%, enhancing corrosion resistance and surface finish, whereas bronze bars often have a balanced alloy composition including copper, tin, and small amounts of phosphorus or aluminum for improved strength. Sheet manufacturing involves rolling processes that produce thin, uniform layers ideal for decorative or architectural applications, while bars are cast or extruded into solid, sturdy forms used in structural or mechanical components. The differing compositions and manufacturing methods directly influence the mechanical properties, ductility, and application suitability of bronze sheets versus bars.

Mechanical Properties Comparison

Bronze sheets exhibit higher tensile strength and improved formability compared to bronze bars, making them ideal for applications requiring precise shaping and durability. Bronze bars, however, typically possess greater hardness and impact resistance, suitable for heavy-duty structural components. The mechanical properties of bronze vary depending on alloy composition, but sheets generally offer enhanced flexibility while bars provide superior load-bearing capacity.

Common Applications of Bronze Sheet

Bronze sheets are widely used in architectural cladding, marine hardware, and decorative art due to their excellent corrosion resistance and ease of fabrication. Unlike bronze bars, which are primarily employed in heavy-duty mechanical components and structural parts, bronze sheets offer superior versatility for crafting intricate designs and thin-walled components. Their applications extend to electrical connectors, musical instruments, and industrial wear plates, leveraging their high strength and conductivity.

Common Applications of Bronze Bar

Bronze bars are widely used in manufacturing heavy-duty components such as gears, bearings, and marine hardware due to their excellent strength, corrosion resistance, and durability. Common applications also include structural parts, bushings, and valve components in automotive and industrial machinery, where precision and wear resistance are critical. Unlike bronze sheets, which are typically employed in decorative and architectural applications, bronze bars provide the robust mechanical properties required for load-bearing and high-stress environments.

Advantages and Disadvantages of Bronze Sheet

Bronze sheets offer greater surface area coverage and flexibility for applications requiring detailed shaping or engraving, making them ideal for decorative and architectural uses. However, they generally have lower structural strength compared to bronze bars, which limits their suitability for heavy load-bearing purposes. The thinness of bronze sheets can also make them more susceptible to dents and deformation, whereas bronze bars provide enhanced durability and strength.

Advantages and Disadvantages of Bronze Bar

Bronze bars offer superior structural strength and versatility in machining, making them ideal for heavy-duty industrial applications compared to bronze sheets. The disadvantages of bronze bars include higher material cost and less flexibility in forming complex shapes, which limits their use in decorative or lightweight projects where bronze sheets excel. Their dense composition provides excellent wear resistance but can increase weight, affecting applications where weight is a critical factor.

Cost and Availability Considerations

Bronze sheets generally cost less than bronze bars due to lower material thickness and easier manufacturing processes, making them a cost-effective choice for projects requiring large surface areas. Availability of bronze sheets is often higher in standard industrial sizes, supporting quick procurement compared to custom-sized bronze bars which may require longer lead times. When budgeting, consider that bronze bars offer more versatility in machining and structural applications but may incur higher costs and limited availability for non-standard dimensions.

Choosing the Right Bronze Form for Your Project

Choosing the right bronze form depends on the specific application requirements; bronze sheets offer excellent surface area for decorative and architectural uses, providing ease of cutting and shaping. Bronze bars, on the other hand, deliver superior strength and rigidity, making them ideal for structural components and machining-intensive projects. Evaluate factors such as thickness, load-bearing needs, and fabrication methods to determine whether bronze sheet or bronze bar best suits your project's functional and aesthetic goals.

Bronze Sheet vs Bronze Bar Infographic

materialdif.com

materialdif.com