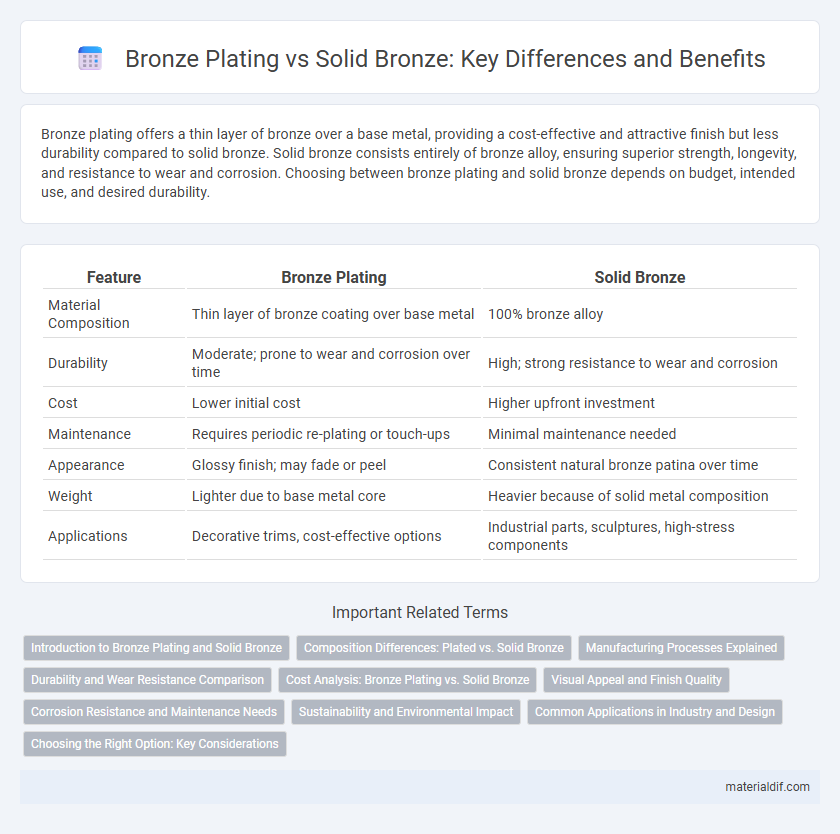

Bronze plating offers a thin layer of bronze over a base metal, providing a cost-effective and attractive finish but less durability compared to solid bronze. Solid bronze consists entirely of bronze alloy, ensuring superior strength, longevity, and resistance to wear and corrosion. Choosing between bronze plating and solid bronze depends on budget, intended use, and desired durability.

Table of Comparison

| Feature | Bronze Plating | Solid Bronze |

|---|---|---|

| Material Composition | Thin layer of bronze coating over base metal | 100% bronze alloy |

| Durability | Moderate; prone to wear and corrosion over time | High; strong resistance to wear and corrosion |

| Cost | Lower initial cost | Higher upfront investment |

| Maintenance | Requires periodic re-plating or touch-ups | Minimal maintenance needed |

| Appearance | Glossy finish; may fade or peel | Consistent natural bronze patina over time |

| Weight | Lighter due to base metal core | Heavier because of solid metal composition |

| Applications | Decorative trims, cost-effective options | Industrial parts, sculptures, high-stress components |

Introduction to Bronze Plating and Solid Bronze

Bronze plating involves applying a thin layer of bronze onto a base metal to achieve the appearance and some corrosion resistance of solid bronze without the full weight or cost. Solid bronze consists entirely of the alloy, primarily copper and tin, offering superior durability, strength, and natural patina development over time. While bronze plating provides an economical and lightweight alternative for decorative purposes, solid bronze ensures long-lasting structural integrity and authentic aging characteristics.

Composition Differences: Plated vs. Solid Bronze

Bronze plating consists of a thin layer of bronze alloy applied over a base metal, typically copper or brass, offering surface-level bronze appearance without the alloy's full properties. Solid bronze is a homogeneous alloy primarily composed of copper and tin, sometimes with added elements like aluminum or phosphorus, providing consistent strength, durability, and corrosion resistance throughout the entire piece. The key compositional difference lies in the plating's superficial bronze layer versus solid bronze's integral alloy makeup, affecting performance, wear, and maintenance.

Manufacturing Processes Explained

Bronze plating involves applying a thin layer of bronze onto a base metal through electroplating or chemical deposition, providing the aesthetic and corrosion resistance of bronze without the full material cost. Solid bronze manufacturing entails casting or forging pure bronze alloys, resulting in components with superior structural integrity and wear resistance, frequently used in heavy-duty applications. The choice between bronze plating and solid bronze depends on desired durability, cost efficiency, and the specific demands of the end product.

Durability and Wear Resistance Comparison

Bronze plating offers a decorative finish but tends to wear off over time, exposing the base metal beneath, which reduces overall durability. Solid bronze provides superior wear resistance and lasts significantly longer in high-friction environments due to its uniform composition. This makes solid bronze ideal for applications requiring sustained mechanical strength and corrosion resistance.

Cost Analysis: Bronze Plating vs. Solid Bronze

Bronze plating offers a cost-effective alternative to solid bronze by applying a thin layer of bronze over a base metal, significantly reducing material expenses while maintaining a similar aesthetic. Solid bronze, although more expensive due to higher raw material and manufacturing costs, provides superior durability, corrosion resistance, and structural integrity. When evaluating cost analysis, bronze plating is ideal for budget-conscious projects requiring visual appeal without the need for the enhanced longevity and strength of solid bronze.

Visual Appeal and Finish Quality

Bronze plating offers a consistent, shiny finish that enhances visual appeal by providing a uniform color and surface texture, ideal for decorative pieces requiring a polished look. Solid bronze, known for its natural patina development, delivers a richer, more authentic aesthetic with greater depth and texture over time, showcasing superior finish quality through aging. While plated bronze excels in immediate brilliance, solid bronze outperforms in durability and long-term visual character.

Corrosion Resistance and Maintenance Needs

Bronze plating offers a thin, decorative layer that provides some corrosion resistance but can wear away over time, exposing the base metal and increasing maintenance needs. Solid bronze, composed of copper and tin alloys, exhibits superior natural corrosion resistance, especially in marine and outdoor environments, requiring minimal upkeep. Regular cleaning and occasional waxing maintain solid bronze's protective patina, whereas bronze plated items demand more frequent inspections and touch-ups to prevent rust and deterioration.

Sustainability and Environmental Impact

Bronze plating involves applying a thin layer of bronze over another metal, reducing raw material usage and extending product life, which can lower overall environmental impact. Solid bronze, being a durable alloy, offers longevity and recyclability, but requires more mining and energy-intensive production compared to plated alternatives. Choosing between bronze plating and solid bronze depends on balancing resource consumption, recycling potential, and product lifespan for sustainable applications.

Common Applications in Industry and Design

Bronze plating offers a cost-effective solution for decorative finishes and corrosion resistance in automotive parts, musical instruments, and architectural hardware. Solid bronze is favored in heavy-duty applications such as marine hardware, sculptures, and industrial machinery components due to its superior durability and wear resistance. Both materials find crucial roles in design and industry, with plating enhancing aesthetics and solid bronze ensuring structural integrity.

Choosing the Right Option: Key Considerations

Bronze plating offers a cost-effective way to achieve the aesthetic appeal and corrosion resistance of bronze without the expense of solid bronze, making it ideal for decorative objects and light-duty applications. Solid bronze, composed mainly of copper and tin, provides superior durability, weight, and longevity, essential for structural components and heavy-use items. When choosing between bronze plating and solid bronze, consider factors such as budget, intended use, environmental exposure, and required mechanical strength to ensure optimal performance and value.

Bronze Plating vs Solid Bronze Infographic

materialdif.com

materialdif.com