Semi-finished bronze products undergo initial processing steps such as casting or rolling, providing a versatile base for further machining or shaping according to specific requirements. Fully-finished bronze items are completed components, precisely machined, polished, and ready for immediate application in industries like aerospace or marine engineering. Choosing between semi-finished and fully-finished bronze depends on project timelines, customization needs, and cost considerations.

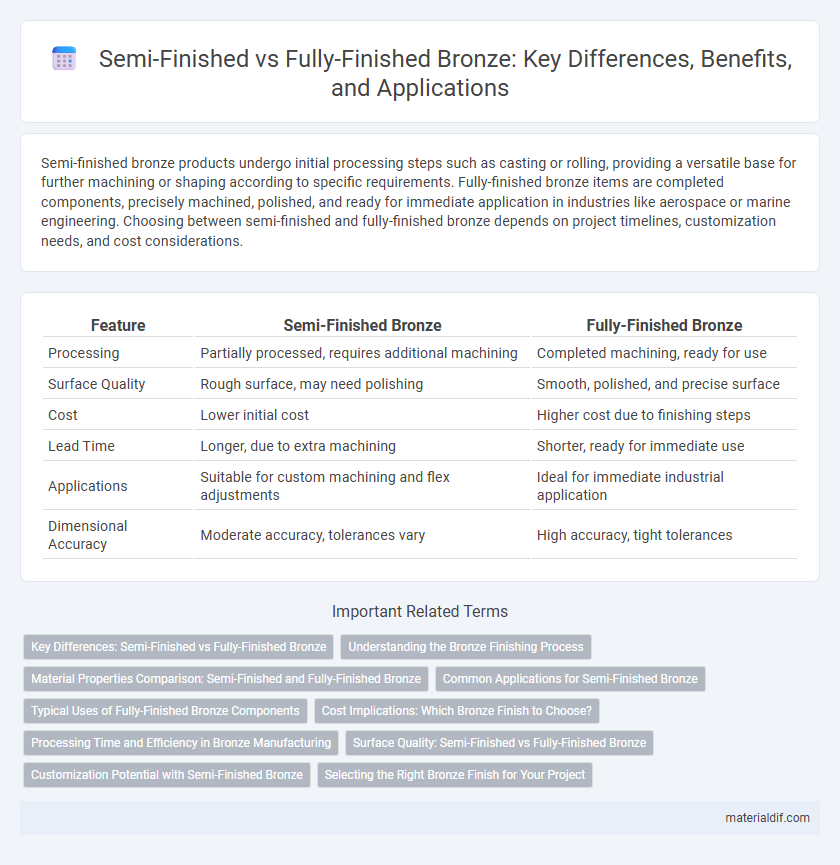

Table of Comparison

| Feature | Semi-Finished Bronze | Fully-Finished Bronze |

|---|---|---|

| Processing | Partially processed, requires additional machining | Completed machining, ready for use |

| Surface Quality | Rough surface, may need polishing | Smooth, polished, and precise surface |

| Cost | Lower initial cost | Higher cost due to finishing steps |

| Lead Time | Longer, due to extra machining | Shorter, ready for immediate use |

| Applications | Suitable for custom machining and flex adjustments | Ideal for immediate industrial application |

| Dimensional Accuracy | Moderate accuracy, tolerances vary | High accuracy, tight tolerances |

Key Differences: Semi-Finished vs Fully-Finished Bronze

Semi-finished bronze refers to bronze products that have undergone initial processing, such as casting or extrusion, but require further machining or finishing to meet precise specifications. Fully-finished bronze, on the other hand, has completed all manufacturing stages, including surface treatment and machining, resulting in a product ready for immediate use or assembly. The key differences lie in application readiness, dimensional accuracy, and surface quality, with fully-finished bronze offering higher precision and aesthetics compared to semi-finished bronze.

Understanding the Bronze Finishing Process

Semi-finished bronze products undergo initial forming processes such as casting or rolling, resulting in items that require further machining or surface treatment to achieve final specifications. Fully-finished bronze components have completed all finishing stages, including precise machining, polishing, and sometimes coating, ensuring optimal mechanical properties and aesthetic quality. Understanding the bronze finishing process is essential for selecting the appropriate material state based on manufacturing needs, cost-efficiency, and desired surface characteristics.

Material Properties Comparison: Semi-Finished and Fully-Finished Bronze

Semi-finished bronze exhibits higher machinability and flexibility, allowing for easier shaping and additional processing compared to fully-finished bronze, which possesses enhanced mechanical strength and superior surface finish. The microstructure of semi-finished bronze retains more uniformity, enabling customization, whereas fully-finished bronze undergoes controlled heat treatment or cold working to maximize wear resistance and corrosion protection. Differences in hardness, tensile strength, and ductility between semi-finished and fully-finished bronze directly impact their suitability for specific industrial applications such as bearings, sculptures, and marine components.

Common Applications for Semi-Finished Bronze

Semi-finished bronze products, such as billets, rods, and sheets, are commonly used in manufacturing industries where further machining or fabrication is required to meet specific design specifications. These forms are ideal for applications in automotive, marine, and electrical components, allowing for customized production of bushings, bearings, gears, and connectors. Semi-finished bronze provides flexibility for precise engineering needs before being transformed into fully-finished parts ready for final assembly.

Typical Uses of Fully-Finished Bronze Components

Fully-finished bronze components are commonly used in precision applications such as bearings, bushings, and marine hardware, where dimensional accuracy and surface finish are critical. These components provide enhanced corrosion resistance and wear performance, making them ideal for aerospace, automotive, and electrical industries. Their ready-to-install condition reduces machining and assembly time, improving manufacturing efficiency.

Cost Implications: Which Bronze Finish to Choose?

Semi-finished bronze products typically incur lower initial costs due to reduced machining and processing, making them ideal for applications with flexible tolerance requirements. Fully-finished bronze involves additional machining, polishing, and quality control, increasing overall expenses but ensuring precise dimensions and superior surface quality for critical components. Choosing between semi-finished and fully-finished bronze depends on budget constraints and the performance demands of the intended application, balancing cost savings with the need for finished specifications.

Processing Time and Efficiency in Bronze Manufacturing

Semi-finished bronze products require less processing time compared to fully-finished bronze due to their partial completion, allowing manufacturers to customize final dimensions and surface finishes based on specific project needs. This phased approach enhances efficiency by reducing the need for extensive machining, polishing, or heat treatment during later stages, leading to cost-effective production cycles. Manufacturers optimize workflow and resource allocation by selecting semi-finished bronze for projects involving complex specifications or large volume runs, while fully-finished bronze suits immediate use with minimal post-processing.

Surface Quality: Semi-Finished vs Fully-Finished Bronze

Semi-finished bronze typically exhibits a rougher surface texture with visible machining marks, suitable for further processing and shaping. Fully-finished bronze offers a smooth, polished surface free from imperfections, enhancing both aesthetic appeal and corrosion resistance. The choice between semi-finished and fully-finished bronze significantly influences the final product's durability and visual quality.

Customization Potential with Semi-Finished Bronze

Semi-finished bronze products offer greater customization potential compared to fully-finished bronze, as they provide manufacturers with raw or partially processed materials ready for further machining, shaping, or finishing. This flexibility enables tailored adjustments to dimensions, surface treatments, and alloy compositions to meet specific application requirements. Semi-finished bronze is ideal for industries requiring precision parts with unique specifications, such as aerospace, automotive, and industrial machinery.

Selecting the Right Bronze Finish for Your Project

Selecting the right bronze finish depends on the project's requirements for durability and aesthetics. Semi-finished bronze offers a cost-effective option with basic machining, suitable for further customization or large-scale manufacturing. Fully-finished bronze provides superior surface quality, precise dimensions, and corrosion resistance, making it ideal for final applications needing high performance and appearance.

Semi-Finished Bronze vs Fully-Finished Bronze Infographic

materialdif.com

materialdif.com