Gunmetal bronze is an alloy primarily composed of copper, tin, and zinc, known for its excellent corrosion resistance and machinability, making it ideal for marine and bearing applications. Bearing bronze, often containing copper, tin, and lead, offers superior wear resistance and low friction properties, specifically designed for use in high-load bearing environments. Both alloys are valued for durability, but gunmetal bronze excels in harsh conditions while bearing bronze thrives in mechanical performance.

Table of Comparison

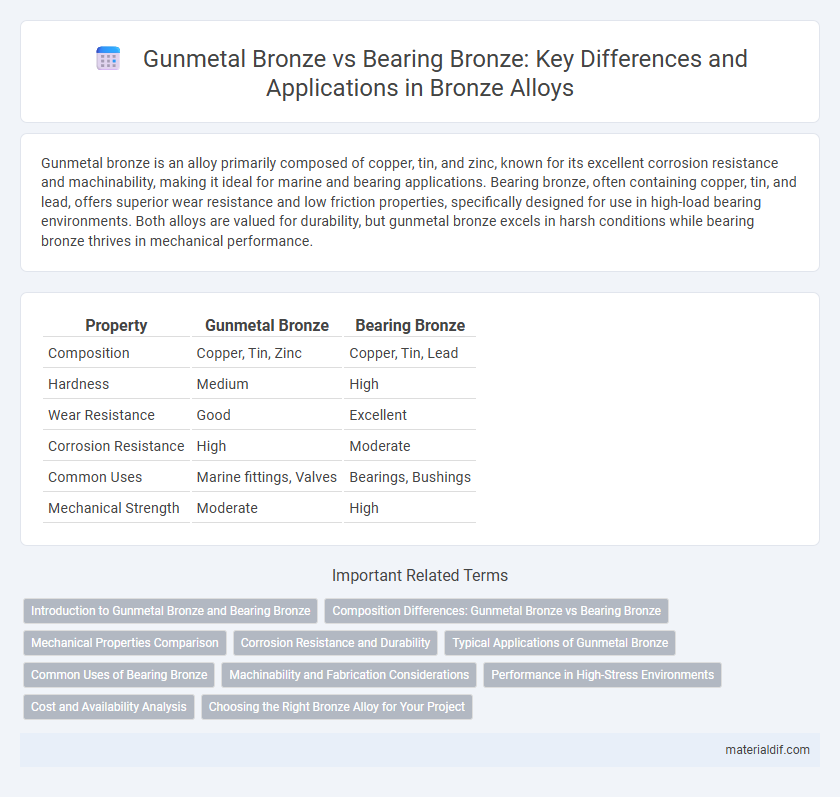

| Property | Gunmetal Bronze | Bearing Bronze |

|---|---|---|

| Composition | Copper, Tin, Zinc | Copper, Tin, Lead |

| Hardness | Medium | High |

| Wear Resistance | Good | Excellent |

| Corrosion Resistance | High | Moderate |

| Common Uses | Marine fittings, Valves | Bearings, Bushings |

| Mechanical Strength | Moderate | High |

Introduction to Gunmetal Bronze and Bearing Bronze

Gunmetal bronze is an alloy primarily composed of copper, tin, and zinc, known for its excellent resistance to corrosion and wear, making it ideal for marine hardware and valves. Bearing bronze, typically consisting of copper, tin, and lead, offers superior friction-reducing properties crucial for high-load bearing applications such as bushings and bearings. Both alloys provide distinct mechanical and chemical properties tailored to specific industrial uses, with gunmetal excelling in durability and bearing bronze optimized for smooth motion and load-bearing performance.

Composition Differences: Gunmetal Bronze vs Bearing Bronze

Gunmetal bronze primarily consists of copper, tin, and zinc, typically around 88% copper, 8-10% tin, and 2-4% zinc, which provides good corrosion resistance and machining properties. Bearing bronze, on the other hand, contains higher amounts of lead and tin along with copper, such as 86% copper, 10% tin, and 4% lead, enhancing its lubricating qualities for bearing applications. The distinct elemental composition of gunmetal bronze favors strength and wear resistance, while bearing bronze's makeup improves friction reduction and load-bearing capacity.

Mechanical Properties Comparison

Gunmetal bronze exhibits higher tensile strength and superior corrosion resistance compared to bearing bronze, making it ideal for heavy-duty applications and marine environments. Bearing bronze offers better load-bearing capacity and enhanced wear resistance due to its composition, which includes tin and lead additives. Both alloys provide excellent machinability, but gunmetal's mechanical properties favor structural uses while bearing bronze is optimized for friction and bearing applications.

Corrosion Resistance and Durability

Gunmetal bronze exhibits superior corrosion resistance due to its high copper and tin content, making it ideal for marine and industrial applications exposed to harsh environments. Bearing bronze, often alloyed with lead or aluminum, offers exceptional wear resistance and durability under heavy loads but may require additional protective coatings in corrosive settings. Both alloys provide durability; however, gunmetal bronze excels in resisting corrosion, while bearing bronze is optimized for mechanical strength and longevity in bearing applications.

Typical Applications of Gunmetal Bronze

Gunmetal bronze is commonly used in marine hardware, valve components, and pipe fittings due to its excellent corrosion resistance and strength. Its typical applications also include bearings, gears, and bushings where durability and wear resistance are essential. This alloy's combination of toughness and machinability makes it ideal for use in harsh environments and mechanical parts requiring high performance.

Common Uses of Bearing Bronze

Bearing bronze is commonly used in applications requiring high wear resistance and low friction, such as bushings, bearings, and thrust washers in automotive and industrial machinery. Its composition, typically including tin and lead, enhances anti-friction properties and load-bearing capacity, making it ideal for moving parts exposed to heavy loads. Gunmetal bronze, while strong and corrosion-resistant, is less suited for these specialized bearing applications due to its different alloy makeup.

Machinability and Fabrication Considerations

Gunmetal bronze exhibits higher machinability due to its lower hardness and better thermal conductivity, making it ideal for precision components requiring complex shapes. Bearing bronze, while offering superior wear resistance and load-bearing capacity, has a denser microstructure that can reduce machining speed and increase tool wear. Fabrication of gunmetal bronze benefits from easier casting and machining processes, whereas bearing bronze demands more controlled machining parameters to maintain material integrity and performance.

Performance in High-Stress Environments

Gunmetal bronze exhibits superior corrosion resistance and strength, making it ideal for high-stress environments involving water exposure and marine applications. Bearing bronze offers excellent load-bearing capacity and wear resistance, optimizing performance in heavy machinery and rotating parts under continuous friction. The choice between the two depends on the specific mechanical stress and environmental conditions, with gunmetal bronze favored for durability in harsh conditions and bearing bronze prioritized for mechanical efficiency.

Cost and Availability Analysis

Gunmetal bronze generally costs more than bearing bronze due to its higher copper and tin content, which enhances corrosion resistance and strength, making it ideal for marine applications. Bearing bronze is more readily available and cost-effective, commonly used in machinery for its excellent wear resistance and low friction properties. Procurement decisions often favor bearing bronze when budget constraints and widespread supplier availability are critical factors.

Choosing the Right Bronze Alloy for Your Project

Gunmetal bronze offers superior corrosion resistance and excellent machinability, making it ideal for marine and industrial applications exposed to harsh environments. Bearing bronze, distinguished by its high strength and low friction properties, excels in heavy-load and high-wear scenarios such as bushings and bearings. Selecting the right bronze alloy depends on balancing mechanical stress, environmental conditions, and wear resistance requirements specific to your project.

Gunmetal Bronze vs Bearing Bronze Infographic

materialdif.com

materialdif.com