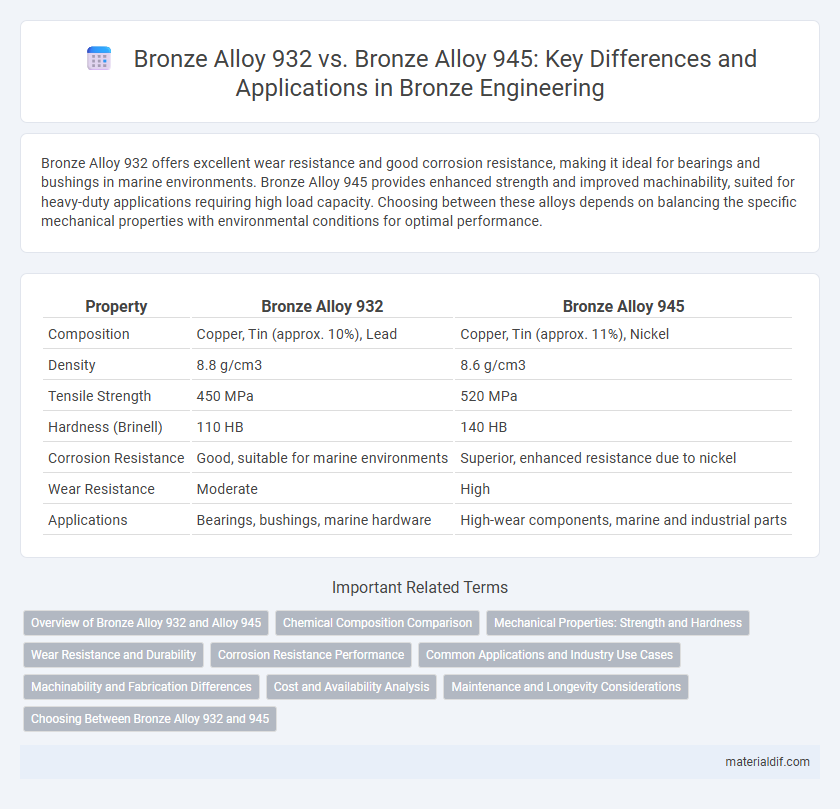

Bronze Alloy 932 offers excellent wear resistance and good corrosion resistance, making it ideal for bearings and bushings in marine environments. Bronze Alloy 945 provides enhanced strength and improved machinability, suited for heavy-duty applications requiring high load capacity. Choosing between these alloys depends on balancing the specific mechanical properties with environmental conditions for optimal performance.

Table of Comparison

| Property | Bronze Alloy 932 | Bronze Alloy 945 |

|---|---|---|

| Composition | Copper, Tin (approx. 10%), Lead | Copper, Tin (approx. 11%), Nickel |

| Density | 8.8 g/cm3 | 8.6 g/cm3 |

| Tensile Strength | 450 MPa | 520 MPa |

| Hardness (Brinell) | 110 HB | 140 HB |

| Corrosion Resistance | Good, suitable for marine environments | Superior, enhanced resistance due to nickel |

| Wear Resistance | Moderate | High |

| Applications | Bearings, bushings, marine hardware | High-wear components, marine and industrial parts |

Overview of Bronze Alloy 932 and Alloy 945

Bronze Alloy 932 is a copper-tin-zinc alloy known for its excellent wear resistance, corrosion resistance, and good mechanical strength, making it suitable for bearings and bushings. Bronze Alloy 945, composed primarily of copper, tin, and small amounts of lead and zinc, offers superior machinability and enhanced fatigue resistance, ideal for intricate components subjected to cyclic loads. Both alloys provide reliable performance in industrial applications but differ in their specific mechanical properties and machining characteristics.

Chemical Composition Comparison

Bronze Alloy 932 typically contains approximately 88-90% copper, 10-12% tin, and traces of phosphorus and other elements, enhancing its strength and corrosion resistance. Bronze Alloy 945 has a higher copper content around 90-92%, with lower tin percentages near 8-9%, and includes small amounts of lead and zinc to improve machinability and wear resistance. The variations in tin and additional alloying elements between these two bronze alloys result in different mechanical properties and suitability for specific industrial applications.

Mechanical Properties: Strength and Hardness

Bronze Alloy 932 exhibits higher tensile strength and superior hardness compared to Bronze Alloy 945 due to its increased copper and tin content. The enhanced mechanical properties make Alloy 932 more suitable for applications requiring greater wear resistance and load-bearing capacity. In contrast, Alloy 945 offers better corrosion resistance but at the expense of slightly lower strength and hardness levels.

Wear Resistance and Durability

Bronze Alloy 932, known for its high tin content, offers excellent wear resistance and durability in heavy-load applications, making it ideal for bearings and bushings. Bronze Alloy 945, with added aluminum and nickel, enhances strength and corrosion resistance, providing superior durability in marine and industrial environments. Both alloys exhibit robust wear properties, but Alloy 945 excels in resistance to oxidative wear and long-term mechanical stability.

Corrosion Resistance Performance

Bronze Alloy 945 exhibits superior corrosion resistance compared to Bronze Alloy 932, particularly in marine and industrial environments due to its higher tin and lead content. Alloy 945's enhanced resistance to dezincification and stress corrosion cracking makes it ideal for applications involving prolonged exposure to seawater and acidic conditions. In contrast, Bronze Alloy 932 offers moderate corrosion resistance but is more prone to surface oxidation and pitting under similar conditions.

Common Applications and Industry Use Cases

Bronze Alloy 932 is widely used in marine hardware, gears, and valve components due to its excellent corrosion resistance and wear properties, making it ideal for harsh environments. Bronze Alloy 945 finds extensive application in electrical connectors, springs, and precision instruments because of its superior electrical conductivity and strength. Both alloys serve critical roles in manufacturing and engineering sectors but are selected based on specific performance requirements in mechanical durability or electrical efficiency.

Machinability and Fabrication Differences

Bronze Alloy 932 offers superior machinability due to its lead content, enabling faster cutting speeds and smoother finishes compared to Bronze Alloy 945, which has lower lead levels and thus reduced machinability. Fabrication-wise, Alloy 932 exhibits better chip formation and less tool wear, making it ideal for complex machining operations, while Alloy 945 requires more cautious handling to avoid tool damage. The trade-offs between these alloys lie in optimizing fabrication efficiency with Alloy 932 versus enhanced corrosion resistance and strength characteristics found in Alloy 945.

Cost and Availability Analysis

Bronze Alloy 932 typically offers lower production costs due to its simpler composition and wider availability of raw materials, making it a budget-friendly option for large-scale manufacturing. Bronze Alloy 945 contains higher percentages of tin and other elements, which increases both material costs and procurement challenges due to limited suppliers. Availability of Alloy 932 is generally more consistent in global markets, whereas Alloy 945's specialized properties can lead to supply constraints and longer lead times.

Maintenance and Longevity Considerations

Bronze Alloy 932 offers excellent corrosion resistance and requires minimal maintenance, making it suitable for applications exposed to harsh environments. Bronze Alloy 945 features higher strength and improved wear resistance, which contributes to enhanced longevity in heavy-duty conditions. Choosing between these alloys depends on balancing maintenance frequency against expected service life, with Alloy 945 often preferred for demanding, high-stress applications.

Choosing Between Bronze Alloy 932 and 945

Choosing between Bronze Alloy 932 and 945 depends primarily on application requirements such as strength, corrosion resistance, and machinability. Bronze Alloy 932, known for its excellent wear resistance and good machinability, is ideal for bearing and bushing applications, while Bronze Alloy 945 offers superior corrosion resistance and higher tensile strength, making it suitable for marine and heavy-duty environments. Evaluating the specific operational conditions and mechanical demands will ensure the optimal choice between these two bronze alloys.

Bronze Alloy 932 vs Bronze Alloy 945 Infographic

materialdif.com

materialdif.com