Bronze finish refers to a surface treatment that mimics the natural look of bronze by using patinas or coatings, offering durability and a rich, warm appearance ideal for decorative items. Bronze plating involves electroplating a thin layer of bronze onto a different metal, enhancing corrosion resistance and providing a bronze aesthetic at a lower cost. Choosing between bronze finish and bronze plating depends on factors like durability requirements, budget, and the intended use of the product.

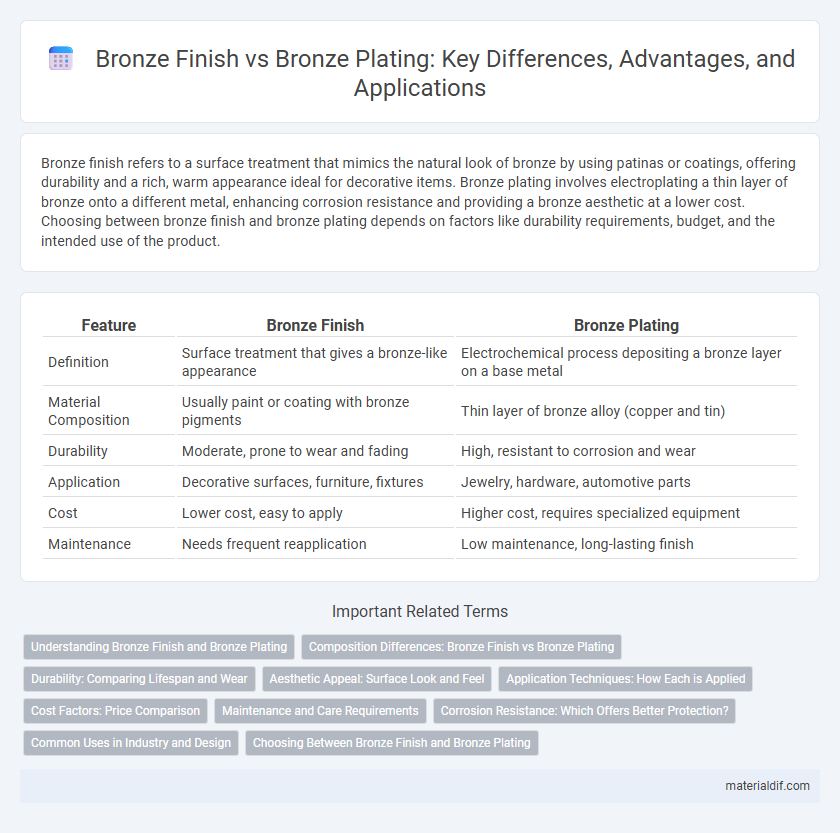

Table of Comparison

| Feature | Bronze Finish | Bronze Plating |

|---|---|---|

| Definition | Surface treatment that gives a bronze-like appearance | Electrochemical process depositing a bronze layer on a base metal |

| Material Composition | Usually paint or coating with bronze pigments | Thin layer of bronze alloy (copper and tin) |

| Durability | Moderate, prone to wear and fading | High, resistant to corrosion and wear |

| Application | Decorative surfaces, furniture, fixtures | Jewelry, hardware, automotive parts |

| Cost | Lower cost, easy to apply | Higher cost, requires specialized equipment |

| Maintenance | Needs frequent reapplication | Low maintenance, long-lasting finish |

Understanding Bronze Finish and Bronze Plating

Bronze finish is a surface treatment that mimics the natural appearance of bronze through patination or chemical processes, enhancing aesthetics and corrosion resistance without adding a new metal layer. Bronze plating involves electroplating a thin layer of bronze alloy onto another metal substrate, providing increased durability, improved wear resistance, and authentic bronze properties. Understanding the differences highlights that bronze finish is primarily cosmetic, while bronze plating adds functional metallic protection.

Composition Differences: Bronze Finish vs Bronze Plating

Bronze finish refers to a surface treatment that mimics the appearance of bronze by applying a color or patina over a base metal, often using paint or chemical processes without altering the metal's core composition. Bronze plating involves electroplating a thin layer of an actual bronze alloy, typically consisting of copper and tin, onto a substrate, enhancing durability and corrosion resistance due to the genuine bronze composition. The key distinction lies in composition: bronze finish is superficial and decorative, while bronze plating provides a functional, metallurgically bonded bronze layer.

Durability: Comparing Lifespan and Wear

Bronze finish typically involves applying a protective coating that enhances corrosion resistance but may wear off over time, resulting in diminished durability. Bronze plating, achieved through electroplating a thin layer of bronze onto a base metal, offers superior lifespan by providing a more consistent and resilient barrier against wear and tarnishing. The durability of bronze plating generally surpasses that of bronze finishing, making it a preferred choice for applications requiring prolonged exposure to harsh conditions.

Aesthetic Appeal: Surface Look and Feel

Bronze finish offers a rich, warm patina characterized by a natural, matte texture that enhances the metal's vintage and rustic aesthetic. Bronze plating provides a smoother, shinier surface with a more uniform color, often achieved through electroplating techniques that create a polished, reflective look. The choice between bronze finish and bronze plating directly impacts the visual depth and tactile experience, influencing the overall design style and interior ambiance.

Application Techniques: How Each is Applied

Bronze finish is typically applied through processes like patination or chemical treatments that create a thin, colored surface layer, often used on decorative items to achieve an antique or rustic look. Bronze plating involves electroplating, where a thin layer of bronze is deposited onto a base metal using an electric current, commonly employed for corrosion resistance and enhanced durability in industrial components. Each technique differs in application equipment and layer thickness, with plating offering a uniform, metal-bonded surface, while finish methods provide varied textures and color effects.

Cost Factors: Price Comparison

Bronze finish typically involves applying a tinted coating that mimics the appearance of bronze at a lower cost compared to bronze plating, which requires electroplating real bronze onto a surface. Bronze plating generally incurs higher expenses due to the use of genuine metal and more complex application processes. For projects prioritizing budget, bronze finish offers a cost-effective alternative without sacrificing the aesthetic appeal of traditional bronze.

Maintenance and Care Requirements

Bronze finish typically requires minimal maintenance, needing only regular dusting and occasional polishing to preserve its natural patina and prevent oxidation. Bronze plating, being a thin layer bonded to a different metal, demands gentle cleaning with non-abrasive materials to avoid wear or peeling, and frequent reapplication may be necessary in high-contact areas. Proper care for both types involves avoiding harsh chemicals and moisture exposure to extend their durability and aesthetic appeal.

Corrosion Resistance: Which Offers Better Protection?

Bronze finish provides a uniform layer that enhances corrosion resistance by forming a stable oxide coating, while bronze plating involves electroplating a thin layer of bronze over a metal substrate, offering variable protection depending on plating thickness and quality. In environments with high moisture or salt exposure, the thicker, solid surface of a bronze finish generally offers superior long-term corrosion resistance compared to bronze plating, which can wear and expose underlying metals to corrosion. Optimal protection requires considering application conditions, but bronze finishes typically outperform plating for durability against oxidation and rust.

Common Uses in Industry and Design

Bronze finish is primarily used in architectural and decorative applications, providing a durable, corrosion-resistant surface with a warm, antique look ideal for door hardware, lighting fixtures, and furniture accents. Bronze plating is common in industrial equipment and electrical connectors, offering enhanced wear resistance and conductivity while maintaining the aesthetic appeal of bronze. Both finishes serve distinct purposes: bronze finish for visual and protective qualities in design, and bronze plating for functional performance in mechanical and electrical industries.

Choosing Between Bronze Finish and Bronze Plating

Bronze finish offers a durable, natural patina that enhances corrosion resistance and develops character over time, making it ideal for decorative applications. Bronze plating provides a thin layer of bronze over another metal, delivering the aesthetic appeal of bronze with cost efficiency but less long-term durability. Choosing between bronze finish and bronze plating depends on whether you prioritize longevity and authentic material properties or budget-friendly decorative appearance.

Bronze Finish vs Bronze Plating Infographic

materialdif.com

materialdif.com