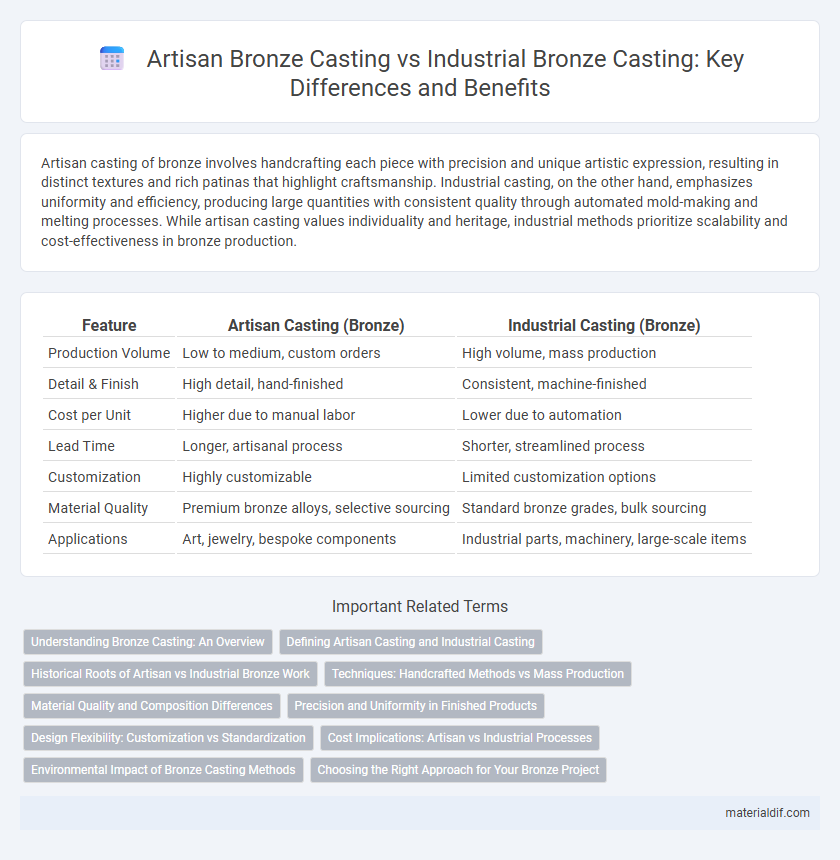

Artisan casting of bronze involves handcrafting each piece with precision and unique artistic expression, resulting in distinct textures and rich patinas that highlight craftsmanship. Industrial casting, on the other hand, emphasizes uniformity and efficiency, producing large quantities with consistent quality through automated mold-making and melting processes. While artisan casting values individuality and heritage, industrial methods prioritize scalability and cost-effectiveness in bronze production.

Table of Comparison

| Feature | Artisan Casting (Bronze) | Industrial Casting (Bronze) |

|---|---|---|

| Production Volume | Low to medium, custom orders | High volume, mass production |

| Detail & Finish | High detail, hand-finished | Consistent, machine-finished |

| Cost per Unit | Higher due to manual labor | Lower due to automation |

| Lead Time | Longer, artisanal process | Shorter, streamlined process |

| Customization | Highly customizable | Limited customization options |

| Material Quality | Premium bronze alloys, selective sourcing | Standard bronze grades, bulk sourcing |

| Applications | Art, jewelry, bespoke components | Industrial parts, machinery, large-scale items |

Understanding Bronze Casting: An Overview

Artisan casting of bronze emphasizes traditional techniques, allowing for intricate details and unique, handcrafted finishes that highlight the material's natural beauty and patina development. Industrial casting employs modern machinery and standardized processes, producing large volumes of consistent, high-precision bronze components suited for mass production. Understanding bronze casting involves recognizing the balance between artisanal craftsmanship for bespoke works and industrial methods for efficiency and scalability.

Defining Artisan Casting and Industrial Casting

Artisan casting of bronze involves handcrafted techniques where skilled artisans manually create detailed molds and pour molten bronze, emphasizing precision and unique artistic expression. Industrial casting uses automated processes such as sand casting or investment casting on a larger scale, prioritizing consistent quality, high volume, and efficiency. Both methods serve different market demands, with artisan casting producing intricate, one-of-a-kind pieces and industrial casting enabling mass production of bronze components.

Historical Roots of Artisan vs Industrial Bronze Work

Artisan casting of bronze traces back to ancient civilizations such as the Egyptians and Greeks, who employed techniques like lost-wax casting to create detailed sculptures and intricate artifacts. Industrial casting emerged in the 19th century with the advent of mechanization, enabling mass production of bronze components for machinery and infrastructure with consistent quality and efficiency. The historical roots highlight artisan casting's emphasis on craftsmanship and unique detail contrasted with industrial casting's focus on scalability and uniformity.

Techniques: Handcrafted Methods vs Mass Production

Artisan casting of bronze employs handcrafting techniques such as lost-wax casting, allowing intricate detailing and unique finishes tailored by skilled craftsmen. Industrial casting relies on mass production methods like sand casting or die casting, emphasizing uniformity and high-volume output with consistent dimensional accuracy. These contrasting approaches impact the bronze's texture, precision, and artistic value, with artisan methods favoring bespoke quality and industrial casting focusing on efficiency.

Material Quality and Composition Differences

Artisan casting of bronze often uses traditional alloys with higher copper content and varying ratios of tin and trace metals, resulting in unique patinas and enhanced aesthetic qualities. Industrial casting typically employs more standardized bronze compositions with precise alloy controls to ensure consistent mechanical properties and durability for mass production. The material quality in artisan casting emphasizes craftsmanship and visual detail, while industrial casting prioritizes uniformity and structural integrity.

Precision and Uniformity in Finished Products

Artisan casting of bronze typically results in unique, handcrafted pieces with slight variations in precision and surface texture, reflecting individual craftsmanship. Industrial casting employs mechanized processes and controlled environments, ensuring high precision, consistent dimensions, and uniformity across large production batches. The industrial approach excels in achieving standardized bronze components with consistent mechanical properties and minimal defects.

Design Flexibility: Customization vs Standardization

Artisan casting of bronze allows for extensive design flexibility, enabling intricate customization tailored to unique artistic visions and small-scale production needs. Industrial casting prioritizes standardization, producing consistent bronze components efficiently through repetitive mold use with limited variation. The contrast highlights artisan casting's adaptability in complex shapes against industrial methods' focus on uniformity and high-volume output.

Cost Implications: Artisan vs Industrial Processes

Artisan casting of bronze typically involves higher labor costs due to manual techniques and extended production times, making it more expensive per unit for small batches. Industrial casting leverages automation and standardized molds, significantly reducing labor costs and enabling economies of scale, thus lowering the overall cost for large production runs. Material waste is generally minimized in industrial processes, further optimizing cost efficiency compared to the more variable yields common in artisan casting.

Environmental Impact of Bronze Casting Methods

Artisan casting of bronze typically generates lower carbon emissions and less hazardous waste due to smaller-scale, manual processes that consume less energy and use traditional, eco-friendly materials. Industrial casting methods involve high-temperature furnaces and large-scale operations, resulting in significant energy consumption and increased release of pollutants such as particulate matter and volatile organic compounds. Selecting artisan bronze casting can reduce environmental impact by minimizing resource use and promoting sustainable practices compared to industrial alternatives.

Choosing the Right Approach for Your Bronze Project

Artisan casting of bronze offers intricate detail and customization, ideal for unique or small-scale projects requiring artistic expression and precise craftsmanship. Industrial casting emphasizes speed, uniformity, and cost-efficiency, making it suitable for large-volume productions with consistent quality standards. Evaluating project scale, budget constraints, and desired finish helps determine whether artisan or industrial casting best suits your bronze fabrication needs.

Artisan Casting vs Industrial Casting (Bronze) Infographic

materialdif.com

materialdif.com