Architectural bronze is prized for its aesthetic appeal, corrosion resistance, and smooth finish, making it ideal for decorative elements like doors, handrails, and window frames. Industrial bronze emphasizes strength, durability, and wear resistance, commonly used in heavy-duty applications such as bearings, gears, and marine hardware. Both types leverage bronze's natural alloy properties but cater to different functional and design requirements in construction and manufacturing.

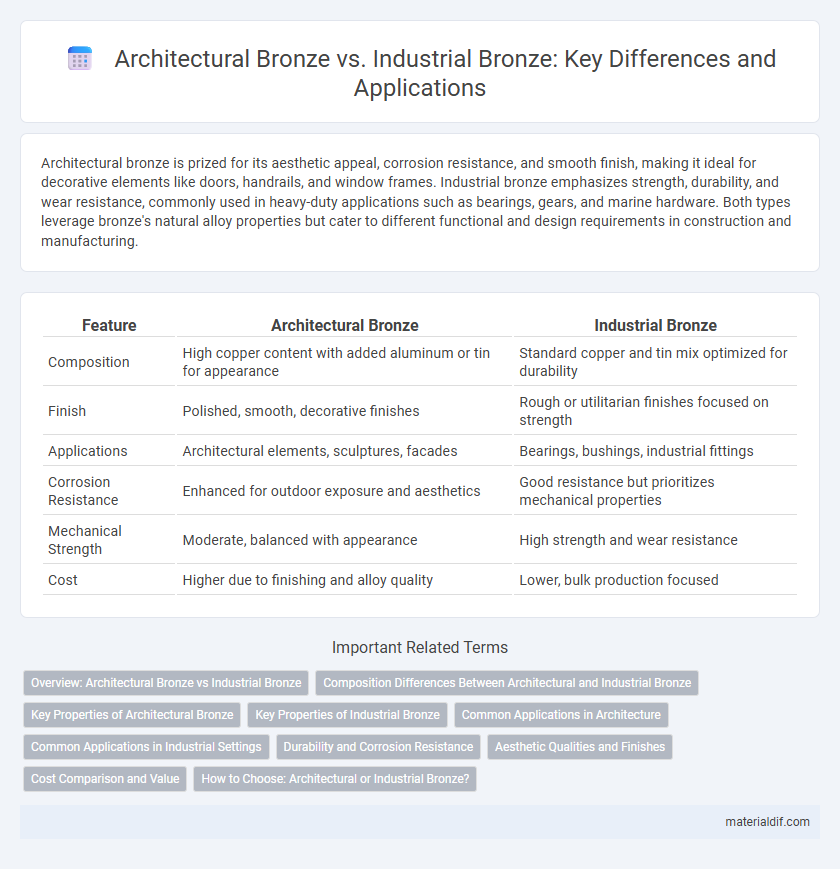

Table of Comparison

| Feature | Architectural Bronze | Industrial Bronze |

|---|---|---|

| Composition | High copper content with added aluminum or tin for appearance | Standard copper and tin mix optimized for durability |

| Finish | Polished, smooth, decorative finishes | Rough or utilitarian finishes focused on strength |

| Applications | Architectural elements, sculptures, facades | Bearings, bushings, industrial fittings |

| Corrosion Resistance | Enhanced for outdoor exposure and aesthetics | Good resistance but prioritizes mechanical properties |

| Mechanical Strength | Moderate, balanced with appearance | High strength and wear resistance |

| Cost | Higher due to finishing and alloy quality | Lower, bulk production focused |

Overview: Architectural Bronze vs Industrial Bronze

Architectural bronze typically features higher copper content with added elements like aluminum and nickel to enhance corrosion resistance and aesthetic appeal, making it ideal for decorative applications such as building facades, door hardware, and sculptures. Industrial bronze prioritizes strength and durability, often incorporating tin and phosphorus to improve wear resistance and mechanical properties for heavy machinery components, bearings, and marine hardware. The distinct alloy compositions optimize architectural bronze for visual excellence and environmental durability, while industrial bronze is engineered for functional performance under mechanical stress.

Composition Differences Between Architectural and Industrial Bronze

Architectural bronze typically contains higher percentages of copper and tin, providing enhanced corrosion resistance and a warm, aesthetic finish ideal for decorative applications. Industrial bronze often includes additional elements such as phosphorus or aluminum to improve strength, wear resistance, and machinability, suited for heavy-duty mechanical parts. The distinct compositions reflect their specific functional requirements, with architectural bronze emphasizing appearance and weather resistance, while industrial bronze prioritizes durability and performance under stress.

Key Properties of Architectural Bronze

Architectural bronze exhibits superior corrosion resistance, aesthetic appeal, and excellent machinability, making it ideal for decorative building elements, monuments, and exterior panels. It combines a copper-tin alloy with added elements such as zinc or lead to enhance durability and maintain a rich, golden-brown finish over time. Unlike industrial bronze, which prioritizes wear resistance and strength for machinery parts, architectural bronze emphasizes long-term stability and visual elegance in exposed environments.

Key Properties of Industrial Bronze

Industrial bronze exhibits superior tensile strength and corrosion resistance compared to architectural bronze, making it ideal for heavy-duty machinery and marine applications. It typically contains higher percentages of tin and other alloying elements that enhance wear resistance and durability under harsh environmental conditions. The alloy's excellent thermal conductivity and machinability contribute to its widespread use in industrial bearings, bushings, and gears.

Common Applications in Architecture

Architectural bronze is widely used in decorative elements such as doors, window frames, and handrails due to its aesthetic appeal and corrosion resistance. Industrial bronze, while also durable, is predominantly utilized for components requiring high strength and wear resistance, like bearings and gears. The distinct alloy compositions optimize architectural bronze for visual and environmental performance, whereas industrial bronze prioritizes mechanical properties for functional applications.

Common Applications in Industrial Settings

Industrial bronze alloys, such as aluminum bronze and manganese bronze, are commonly used in heavy machinery components, marine hardware, and bearing applications due to their superior strength, corrosion resistance, and wear properties. Architectural bronze is typically reserved for decorative elements like door frames and window sills, whereas industrial bronze excels in settings requiring durability and resistance to harsh environments. Applications in industrial settings often include valve components, gears, pumps, and electrical connectors where mechanical integrity and longevity under stress are critical.

Durability and Corrosion Resistance

Architectural bronze features enhanced durability and superior corrosion resistance due to its refined alloy composition, making it ideal for exterior design elements exposed to weather conditions. Industrial bronze, while strong, often includes higher levels of impurities that reduce its corrosion resistance, limiting its effectiveness in marine or harsh environments. The precise balance of copper, tin, and trace metals in architectural bronze ensures long-lasting performance and aesthetic appeal.

Aesthetic Qualities and Finishes

Architectural bronze is prized for its rich, warm hues and smooth, polished finishes that enhance aesthetic appeal in design applications such as facades, doors, and decorative trims. Industrial bronze, by contrast, emphasizes durability and corrosion resistance with finishes that prioritize function over form, often featuring rougher textures or protective coatings. The choice of bronze type directly impacts the visual elegance and longevity of the material in specific environments.

Cost Comparison and Value

Architectural bronze typically carries a higher cost than industrial bronze due to its superior finish, corrosion resistance, and aesthetic appeal, making it ideal for visible design elements such as doors, railings, and decorative features. Industrial bronze, while more affordable, is valued for its strength and durability in functional applications like bearings and machinery components where appearance is less critical. Investing in architectural bronze provides long-term value through enhanced visual appeal and reduced maintenance, whereas industrial bronze offers cost-efficiency in high-wear environments requiring robust performance.

How to Choose: Architectural or Industrial Bronze?

Choosing between architectural bronze and industrial bronze depends on the specific application and desired properties. Architectural bronze is favored for its aesthetic appeal, corrosion resistance, and smooth finish, making it ideal for decorative elements, facades, and interior details. Industrial bronze, designed for durability and mechanical strength, suits heavy-duty applications such as bearings, gears, and machinery components where wear resistance is critical.

Architectural Bronze vs Industrial Bronze Infographic

materialdif.com

materialdif.com