Machinable bronze is specifically formulated for ease of cutting and shaping, making it ideal for intricate components and precision parts. Bearing bronze contains higher levels of lead or other lubricating elements, enhancing its wear resistance and reducing friction in moving parts such as bushings and bearings. Choosing between machinable and bearing bronze depends on the application requirements for machinability versus durability under load.

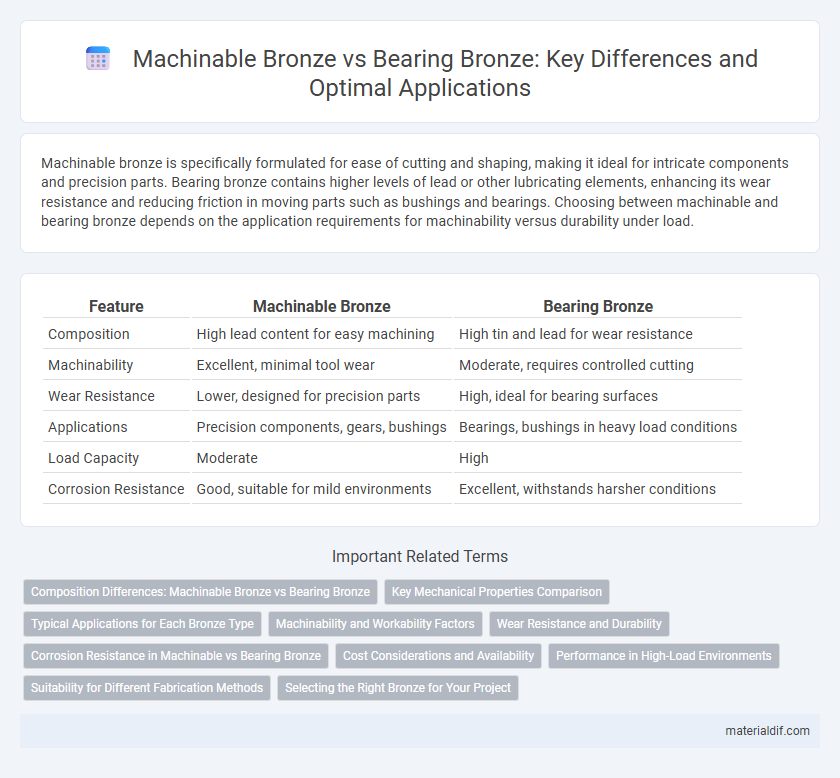

Table of Comparison

| Feature | Machinable Bronze | Bearing Bronze |

|---|---|---|

| Composition | High lead content for easy machining | High tin and lead for wear resistance |

| Machinability | Excellent, minimal tool wear | Moderate, requires controlled cutting |

| Wear Resistance | Lower, designed for precision parts | High, ideal for bearing surfaces |

| Applications | Precision components, gears, bushings | Bearings, bushings in heavy load conditions |

| Load Capacity | Moderate | High |

| Corrosion Resistance | Good, suitable for mild environments | Excellent, withstands harsher conditions |

Composition Differences: Machinable Bronze vs Bearing Bronze

Machinable bronze typically contains higher lead content, around 8-12%, to enhance its cutting and shaping capabilities, while bearing bronze usually has lower lead levels and a higher concentration of tin and copper for superior wear resistance and load-bearing capacity. The presence of lead in machinable bronze reduces friction during machining, making it ideal for complex components, whereas bearing bronze's composition prioritizes durability and performance in rotational applications. These compositional differences directly impact the mechanical properties and suitability of each bronze type in industrial applications.

Key Mechanical Properties Comparison

Machinable bronze offers excellent machinability with tensile strength typically ranging from 50,000 to 120,000 psi, making it ideal for precision parts that require intricate machining. Bearing bronze, known for superior wear resistance and a tensile strength between 40,000 and 90,000 psi, excels in load-bearing applications with high friction and continuous motion. Both alloys provide good corrosion resistance, but machinable bronze is optimized for shaping, while bearing bronze is tailored for durability under mechanical stress.

Typical Applications for Each Bronze Type

Machinable bronze is commonly used in precision components such as gears, valves, and fittings, where ease of machining and tight tolerances are critical. Bearing bronze is specially formulated for high-load and low-friction applications like bushings, bearings, and wear plates in industrial machinery. Each type is selected based on mechanical properties suited to either complex machining processes or extended wear resistance under dynamic loads.

Machinability and Workability Factors

Machinable bronze typically contains lead or bismuth additives that enhance cutting performance, resulting in superior machinability with reduced tool wear and smoother finishes compared to bearing bronze. Bearing bronze, often alloyed with tin and phosphorus, prioritizes wear resistance and load-bearing capacity, which can reduce its workability and complicate machining processes. The choice between machinable and bearing bronze hinges on balancing ease of fabrication against the application's durability and frictional requirements.

Wear Resistance and Durability

Machinable bronze typically offers moderate wear resistance and is engineered for ease of fabrication, making it ideal for applications requiring precision machining. Bearing bronze, often composed with higher levels of tin or lead, provides superior wear resistance and exceptional durability under high-load, sliding conditions. Its enhanced material properties extend component life in bearing applications by reducing friction and resisting deformation.

Corrosion Resistance in Machinable vs Bearing Bronze

Machinable bronze typically contains lead or other additives that enhance its ease of fabrication but may reduce its corrosion resistance compared to bearing bronze. Bearing bronze is specifically alloyed with ingredients like tin and phosphorus that significantly improve its corrosion resistance, making it suitable for harsh or lubricated environments. The superior corrosion resistance of bearing bronze ensures longer service life in applications involving moisture or chemical exposure.

Cost Considerations and Availability

Machinable bronze typically costs less than bearing bronze due to its simpler alloy composition and widespread manufacturing, making it more readily available for general applications. Bearing bronze, designed for superior wear resistance and load-bearing capability, often commands higher prices and may have limited availability depending on specific grade requirements. Cost considerations must balance initial material expense against long-term durability and maintenance needs in selecting between machinable and bearing bronze.

Performance in High-Load Environments

Machinable bronze offers excellent dimensional stability and ease of fabrication but may experience wear under extreme load conditions, making it suitable for moderate applications. Bearing bronze, specifically engineered with higher load-bearing capacity and superior friction resistance, excels in heavy-duty environments requiring prolonged durability and minimal maintenance. High-load performance in bearing bronze is enhanced by its alloy composition, which ensures exceptional strength and abrasion resistance compared to machinable bronze grades.

Suitability for Different Fabrication Methods

Machinable bronze features a fine-grain structure that enables precise and efficient cutting, making it ideal for complex components requiring tight tolerances. Bearing bronze, with its alloy composition optimized for wear resistance and low friction, suits casting and forging processes to produce durable parts for rotational applications. Selecting between machinable and bearing bronze depends on the fabrication method compatibility and end-use performance criteria in industrial manufacturing.

Selecting the Right Bronze for Your Project

Selecting the right bronze alloy involves understanding the differences between machinable bronze and bearing bronze to meet specific project requirements. Machinable bronze offers excellent machinability and is ideal for intricate parts requiring precision machining, while bearing bronze is formulated for superior wear resistance and load-bearing capabilities in friction applications. Evaluating factors such as mechanical strength, corrosion resistance, and operational environment ensures optimal performance and longevity in your chosen bronze material.

Machinable Bronze vs Bearing Bronze Infographic

materialdif.com

materialdif.com