Bearing bronze is engineered for high strength and wear resistance, making it ideal for industrial applications that require durability under heavy loads and friction. Coinage bronze, typically composed of a copper-zinc-tin alloy, is valued for its aesthetic appeal and corrosion resistance, commonly used in minting coins and decorative items. The key difference lies in their composition and purpose: bearing bronze prioritizes mechanical performance, while coinage bronze emphasizes appearance and longevity in circulation.

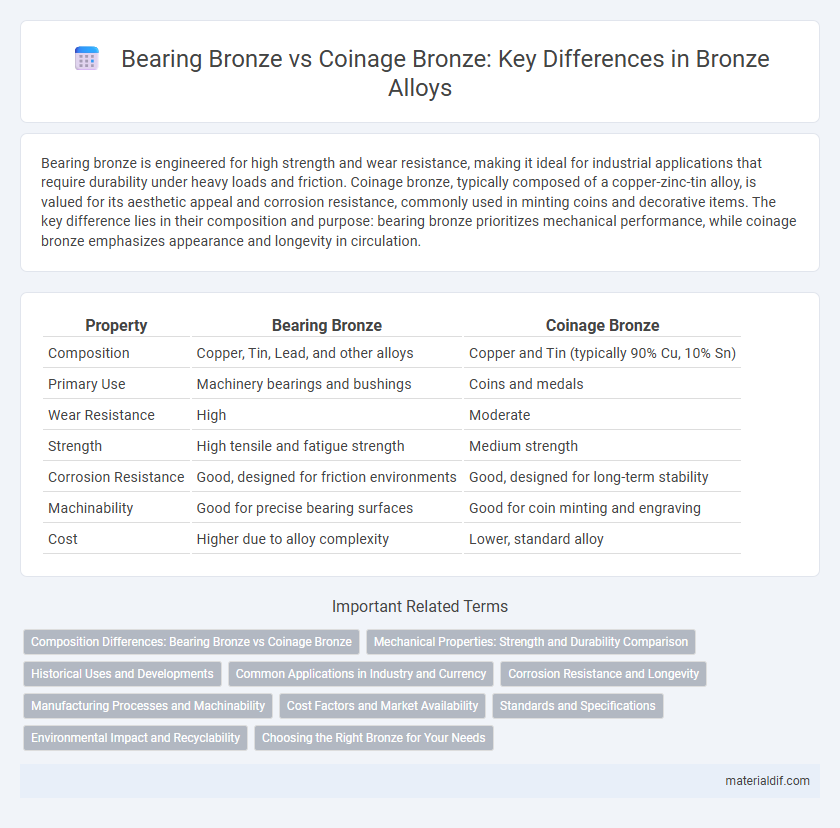

Table of Comparison

| Property | Bearing Bronze | Coinage Bronze |

|---|---|---|

| Composition | Copper, Tin, Lead, and other alloys | Copper and Tin (typically 90% Cu, 10% Sn) |

| Primary Use | Machinery bearings and bushings | Coins and medals |

| Wear Resistance | High | Moderate |

| Strength | High tensile and fatigue strength | Medium strength |

| Corrosion Resistance | Good, designed for friction environments | Good, designed for long-term stability |

| Machinability | Good for precise bearing surfaces | Good for coin minting and engraving |

| Cost | Higher due to alloy complexity | Lower, standard alloy |

Composition Differences: Bearing Bronze vs Coinage Bronze

Bearing bronze primarily consists of a high percentage of copper combined with tin and small amounts of lead or aluminum to enhance wear resistance and reduce friction, making it ideal for mechanical applications. Coinage bronze features a balanced alloy of copper, typically around 88%, with tin and zinc to achieve a harder, more corrosion-resistant material suitable for minting coins. The key compositional difference lies in the presence of lead or aluminum in bearing bronze for improved lubrication properties, whereas coinage bronze emphasizes a zinc-tin blend for durability and aesthetic appeal.

Mechanical Properties: Strength and Durability Comparison

Bearing bronze exhibits superior strength and wear resistance due to its high tin and lead content, making it ideal for heavy-load applications. Coinage bronze, primarily composed of copper and tin with minimal additives, offers moderate strength but excels in corrosion resistance and aesthetic appeal. The durability of bearing bronze under mechanical stress surpasses coinage bronze, which is optimized for decorative and corrosion-resistant uses rather than high mechanical performance.

Historical Uses and Developments

Bearing bronze, historically utilized for its high durability and friction resistance, became essential in industrial applications such as bushings and bearings during the 19th century. Coinage bronze, primarily composed of copper, tin, and zinc, emerged prominently in the 18th and 19th centuries for minting coins due to its corrosion resistance and aesthetic appeal. The development of bearing bronze focused on mechanical performance improvements, while coinage bronze advancements emphasized metal purity and consistent alloy composition for reliable currency production.

Common Applications in Industry and Currency

Bearing bronze is widely used in industrial applications such as bushings, bearings, and wear-resistant components due to its high strength and excellent frictional properties. Coinage bronze typically appears in the minting of coins and medals because of its corrosion resistance and attractive finish. Both types of bronze offer durability, but bearing bronze is optimized for mechanical functions while coinage bronze prioritizes aesthetic and preservation qualities.

Corrosion Resistance and Longevity

Bearing bronze exhibits superior corrosion resistance due to its alloy composition, which typically includes tin and phosphorus, enhancing its durability in harsh environments. Coinage bronze, primarily composed of copper and tin, offers moderate corrosion resistance but is more prone to surface oxidation over time. Bearing bronze's enhanced longevity makes it ideal for mechanical applications requiring sustained performance under stress and exposure to corrosive elements.

Manufacturing Processes and Machinability

Bearing bronze is manufactured using a casting process that emphasizes uniform distribution of tin and other lubricating elements, enhancing wear resistance and durability in heavy-load applications. Coinage bronze, primarily composed of copper and tin, is produced through rolling and annealing processes that optimize its surface finish and malleability for intricate designs. Bearing bronze exhibits superior machinability due to its controlled alloy composition and microstructure, allowing precise machining without compromising strength, while coinage bronze offers moderate machinability suited to decorative and minting purposes.

Cost Factors and Market Availability

Bearing bronze typically contains higher amounts of tin and lead, increasing material costs compared to coinage bronze, which mainly consists of copper and tin with less expensive alloying elements. Market availability of bearing bronze is more limited due to its specialized use in industrial applications, whereas coinage bronze enjoys broader distribution driven by demand in minting and decorative industries. Price fluctuations in tin and lead significantly impact bearing bronze costs, while coinage bronze prices are more stable, influenced primarily by copper market trends.

Standards and Specifications

Bearing Bronze meets stringent ASTM B435 standards, specifying high resistance to wear and corrosion for use in heavy-load applications. Coinage Bronze conforms to ASTM B103 and B189, emphasizing chemical composition with precise copper-tin ratios to ensure durability and optimal color for minting coins. Both materials are engineered to exact metallurgical specifications to guarantee performance in their respective industrial and numismatic uses.

Environmental Impact and Recyclability

Bearing bronze, primarily composed of copper, tin, and lead, offers high durability and resistance to wear, which extends the lifecycle of components and reduces material waste. Coinage bronze, often alloyed with copper and tin, has a lower environmental impact due to its simpler composition and higher recyclability rates, enabling efficient material recovery without hazardous byproducts. Both alloys contribute to sustainability through recyclability, but coinage bronze presents a greener option for applications with less mechanical stress.

Choosing the Right Bronze for Your Needs

Bearing bronze offers high strength and excellent wear resistance, making it ideal for mechanical applications requiring durability and low friction, such as bushings and bearings. Coinage bronze, typically composed of copper and tin with a more refined finish, is chosen for its aesthetic appeal and corrosion resistance, suitable for medals, coins, and decorative items. Selecting the right bronze depends on balancing mechanical performance with visual properties based on your specific project requirements.

Bearing Bronze vs Coinage Bronze Infographic

materialdif.com

materialdif.com