Traditional bronze, composed primarily of copper and tin, offers a timeless aesthetic and excellent corrosion resistance, making it ideal for sculptures and architectural elements. Modern bronze alloys incorporate additional metals like aluminum, nickel, or phosphorus to enhance strength, durability, and machinability for industrial applications. The choice between traditional and modern bronze depends on the balance between historical authenticity and performance requirements.

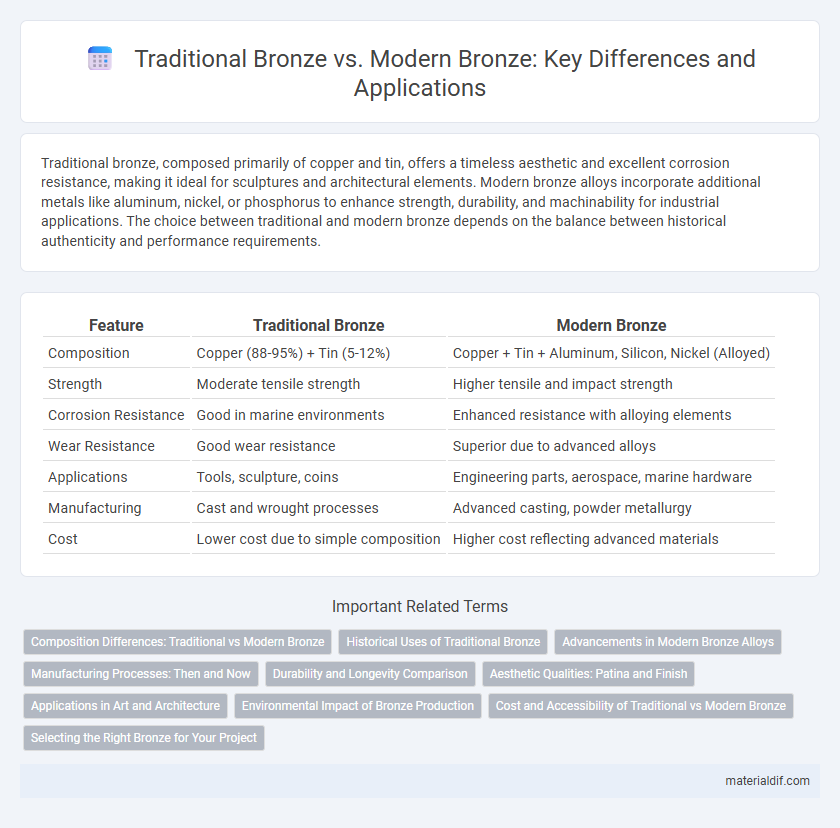

Table of Comparison

| Feature | Traditional Bronze | Modern Bronze |

|---|---|---|

| Composition | Copper (88-95%) + Tin (5-12%) | Copper + Tin + Aluminum, Silicon, Nickel (Alloyed) |

| Strength | Moderate tensile strength | Higher tensile and impact strength |

| Corrosion Resistance | Good in marine environments | Enhanced resistance with alloying elements |

| Wear Resistance | Good wear resistance | Superior due to advanced alloys |

| Applications | Tools, sculpture, coins | Engineering parts, aerospace, marine hardware |

| Manufacturing | Cast and wrought processes | Advanced casting, powder metallurgy |

| Cost | Lower cost due to simple composition | Higher cost reflecting advanced materials |

Composition Differences: Traditional vs Modern Bronze

Traditional bronze primarily consists of copper alloyed with tin, typically ranging from 10% to 12%, offering excellent corrosion resistance and hardness suited for artistic and structural use. Modern bronze alloys incorporate additional elements such as aluminum, nickel, and manganese, enhancing mechanical strength, wear resistance, and suitability for industrial applications. These compositional differences result in traditional bronze favoring aesthetic and historical uses, while modern bronze targets engineering performance and specialized functions.

Historical Uses of Traditional Bronze

Traditional bronze, primarily an alloy of copper and tin, was extensively used in historical artifacts such as tools, weapons, and sculptures due to its superior hardness and corrosion resistance compared to pure copper. Ancient civilizations, including the Egyptians, Greeks, and Chinese, relied on traditional bronze for crafting intricate armor, ceremonial objects, and durable household items. Its historical significance is reflected in the Bronze Age, a pivotal period marked by advancements in metallurgy and societal development driven by the widespread use of this alloy.

Advancements in Modern Bronze Alloys

Modern bronze alloys have evolved significantly from traditional compositions by incorporating elements such as aluminum, silicon, and nickel, enhancing strength, corrosion resistance, and wear properties. These advancements enable applications in aerospace, marine engineering, and electronics where superior durability and performance are critical. The controlled microstructure in modern bronze alloys also improves machinability and thermal stability compared to traditional tin-copper bronze.

Manufacturing Processes: Then and Now

Traditional bronze manufacturing involved hand-casting and alloying primarily copper with tin using primitive furnaces and molds, resulting in variable quality and limited precision. Modern bronze production employs advanced casting techniques such as centrifugal casting and continuous casting, combined with precise control over alloy composition through automated processes, ensuring consistent strength and improved durability. Innovations in metallurgy and computer-aided design have further enhanced the manufacturing efficiency and performance characteristics of modern bronze alloys.

Durability and Longevity Comparison

Traditional bronze, composed primarily of copper and tin, offers excellent corrosion resistance and has been valued for its longevity in historical artifacts lasting centuries. Modern bronze alloys often incorporate elements like aluminum, silicon, or phosphorus, enhancing wear resistance, strength, and durability beyond traditional compositions. These advancements result in modern bronze exhibiting superior mechanical properties and extended service life in industrial applications compared to its traditional counterpart.

Aesthetic Qualities: Patina and Finish

Traditional bronze develops a rich, natural patina over time, characterized by deep greens and browns that enhance its antique appeal and historical authenticity. Modern bronze often features improved finishes, including protective coatings and controlled patination techniques that maintain a uniform appearance and offer higher durability. The aesthetic qualities of traditional bronze emphasize organic aging processes, while modern bronze prioritizes consistency and customized finishes for contemporary design applications.

Applications in Art and Architecture

Traditional bronze, an alloy primarily of copper and tin, has been favored in sculpture and architectural details for its durability and warm, golden-brown patina that enhances historic aesthetics. Modern bronze alloys often incorporate elements like aluminum, manganese, or phosphorus, improving corrosion resistance and tensile strength, making them ideal for contemporary public art installations and structural components exposed to harsh environments. Both traditional and modern bronzes continue to be integral in creating enduring, visually appealing works in art and architecture, balancing timeless craftsmanship with advanced material performance.

Environmental Impact of Bronze Production

Traditional bronze production involved higher carbon emissions due to primitive smelting techniques and the use of charcoal, contributing to deforestation and air pollution. Modern bronze manufacturing utilizes advanced technologies such as induction melting and recycled materials, significantly reducing energy consumption and waste generation. Innovations in eco-friendly alloy compositions and closed-loop recycling systems further minimize the environmental footprint of bronze production.

Cost and Accessibility of Traditional vs Modern Bronze

Traditional bronze, typically an alloy of copper and tin, tends to be more expensive due to the scarcity and higher cost of tin compared to other alloying elements. Modern bronze formulations often incorporate alternative metals like aluminum, silicon, or phosphorus, reducing overall material costs and increasing accessibility for industrial applications. The availability of modern alloying elements and advances in manufacturing techniques make modern bronze more cost-effective and widely accessible than traditional bronze.

Selecting the Right Bronze for Your Project

Traditional bronze, composed primarily of copper and tin, offers excellent corrosion resistance and a classic aesthetic ideal for historical restorations and sculptures, while modern bronze alloys often incorporate elements like aluminum, manganese, or nickel to enhance strength, wear resistance, and machinability. Selecting the right bronze depends on project-specific requirements such as environmental exposure, mechanical stress, and desired finish, with standard alloys like C93200 favored for bearing applications and C95400 chosen for architectural detailing. Evaluating factors including tensile strength, melting point, and cost efficiency ensures optimal material performance and longevity in both traditional craftsmanship and advanced industrial uses.

Traditional Bronze vs Modern Bronze Infographic

materialdif.com

materialdif.com