Marine bronze offers superior corrosion resistance in saltwater environments due to its higher content of elements like tin and aluminum, making it ideal for ship fittings and underwater components. Industrial bronze prioritizes strength and wear resistance, often incorporating additives such as manganese or nickel to withstand mechanical stress in heavy machinery. Both types provide excellent durability, but their specific alloy compositions tailor them to different environmental and operational demands.

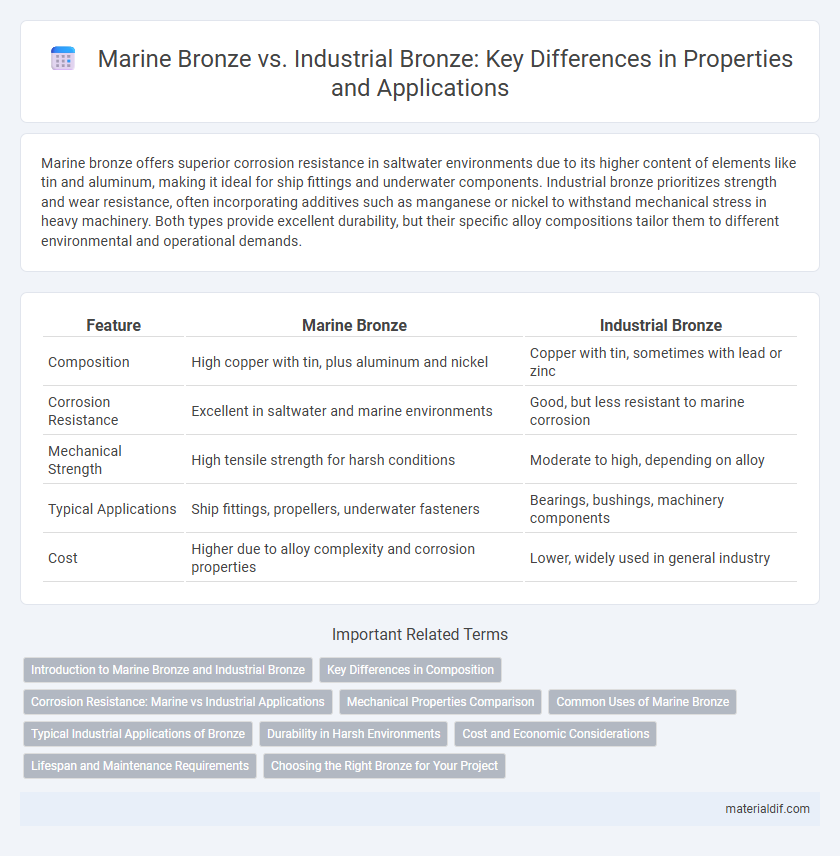

Table of Comparison

| Feature | Marine Bronze | Industrial Bronze |

|---|---|---|

| Composition | High copper with tin, plus aluminum and nickel | Copper with tin, sometimes with lead or zinc |

| Corrosion Resistance | Excellent in saltwater and marine environments | Good, but less resistant to marine corrosion |

| Mechanical Strength | High tensile strength for harsh conditions | Moderate to high, depending on alloy |

| Typical Applications | Ship fittings, propellers, underwater fasteners | Bearings, bushings, machinery components |

| Cost | Higher due to alloy complexity and corrosion properties | Lower, widely used in general industry |

Introduction to Marine Bronze and Industrial Bronze

Marine bronze, often alloyed with copper, tin, and small amounts of zinc and nickel, offers exceptional corrosion resistance and strength in seawater environments, making it ideal for shipbuilding, propellers, and underwater fastenings. Industrial bronze typically contains higher amounts of lead or aluminum to enhance machinability and wear resistance, suited for bearings, gears, and heavy machinery components exposed to mechanical stress. Both types embody tailored metallurgical compositions to optimize performance in their respective marine and industrial applications.

Key Differences in Composition

Marine bronze contains higher proportions of tin and nickel, enhancing corrosion resistance in saltwater environments, while industrial bronze typically includes more zinc and sometimes lead for improved machinability. The presence of these alloying elements directly influences the metal's hardness, tensile strength, and durability under specific operating conditions. Understanding these compositional differences is crucial for selecting the appropriate bronze type in marine versus industrial applications.

Corrosion Resistance: Marine vs Industrial Applications

Marine bronze exhibits superior corrosion resistance due to its high copper content and the addition of elements like tin and zinc, which enhance its ability to withstand saltwater environments. Industrial bronze, while still resistant to corrosion, often contains different alloying elements tailored for mechanical strength rather than prolonged exposure to marine conditions. The enhanced corrosion resistance in marine bronze makes it ideal for ship fittings, propellers, and underwater components, whereas industrial bronze suits applications such as bearings and bushings in less corrosive atmospheres.

Mechanical Properties Comparison

Marine bronze exhibits superior corrosion resistance and tensile strength compared to industrial bronze, making it ideal for harsh saltwater environments. Industrial bronze typically offers higher hardness and better wear resistance suited for heavy machinery and structural applications. The mechanical properties of marine bronze include enhanced ductility and fatigue resistance, ensuring durability in dynamic marine conditions, whereas industrial bronze prioritizes load-bearing capacity and abrasion resistance.

Common Uses of Marine Bronze

Marine bronze, an alloy primarily composed of copper, tin, and small amounts of zinc or lead, is specially formulated to resist corrosion in saltwater environments, making it ideal for shipbuilding and marine hardware applications. Its common uses include propellers, underwater fasteners, ship fittings, and pump components due to its exceptional strength and resistance to biofouling. Industrial bronze, while durable, lacks this specialized resistance and is typically utilized in machinery bearings, bushings, and electrical connectors where exposure to water is minimal.

Typical Industrial Applications of Bronze

Marine bronze, known for its superior corrosion resistance in seawater environments, is commonly used in shipbuilding, propellers, and underwater fastenings. Industrial bronze, with enhanced mechanical strength and wear resistance, finds applications in gears, bearings, bushings, and electrical connectors. Typical industrial uses leverage bronze's durability, machinability, and conductivity to ensure performance in heavy machinery, automotive components, and electrical equipment.

Durability in Harsh Environments

Marine bronze contains higher levels of elements like tin and zinc, enhancing its corrosion resistance in saltwater and high-moisture settings, making it ideal for ship fittings and underwater applications. Industrial bronze typically has a balanced composition optimized for mechanical strength and wear resistance in dry or mildly corrosive environments. The superior durability of marine bronze in harsh, saline conditions ensures longer service life and reduced maintenance compared to industrial bronze.

Cost and Economic Considerations

Marine bronze generally incurs higher costs than industrial bronze due to its superior corrosion resistance and enhanced alloy composition that withstands harsh saltwater environments. Industrial bronze, while more affordable, suits applications with less exposure to moisture, enabling cost savings on materials and maintenance. Selecting between marine and industrial bronze hinges on balancing initial expenditure against long-term durability and potential replacement costs.

Lifespan and Maintenance Requirements

Marine bronze, designed to resist corrosion in saltwater environments, typically offers a longer lifespan than industrial bronze when exposed to harsh marine conditions, often exceeding 50 years with proper maintenance. It requires regular cleaning and anti-fouling treatments to maintain its protective patina and prevent biofouling. Industrial bronze, while durable in controlled environments, can experience accelerated wear and corrosion in marine settings, leading to shorter service life and more intensive maintenance routines.

Choosing the Right Bronze for Your Project

Marine bronze, typically composed of copper, tin, and zinc, offers exceptional corrosion resistance against saltwater, making it ideal for ship fittings, propellers, and underwater components. Industrial bronze, often alloyed with aluminum or nickel, provides enhanced strength and wear resistance suitable for heavy machinery, bearings, and structural parts. Selecting the right bronze depends on environmental exposure and mechanical demands, with marine bronze preferred for aquatic applications and industrial bronze favored for high-stress, abrasive conditions.

Marine Bronze vs Industrial Bronze Infographic

materialdif.com

materialdif.com