Coinage bronze is primarily an alloy of copper and tin, designed for durability and resistance to wear, making it ideal for minting coins that can withstand frequent handling. Architectural bronze, on the other hand, often contains additional elements like aluminum, silicon, or manganese to enhance strength, corrosion resistance, and aesthetic appeal for use in building facades, fixtures, and decorative elements. The distinct compositions of these bronzes optimize their performance for either currency production or structural and ornamental applications.

Table of Comparison

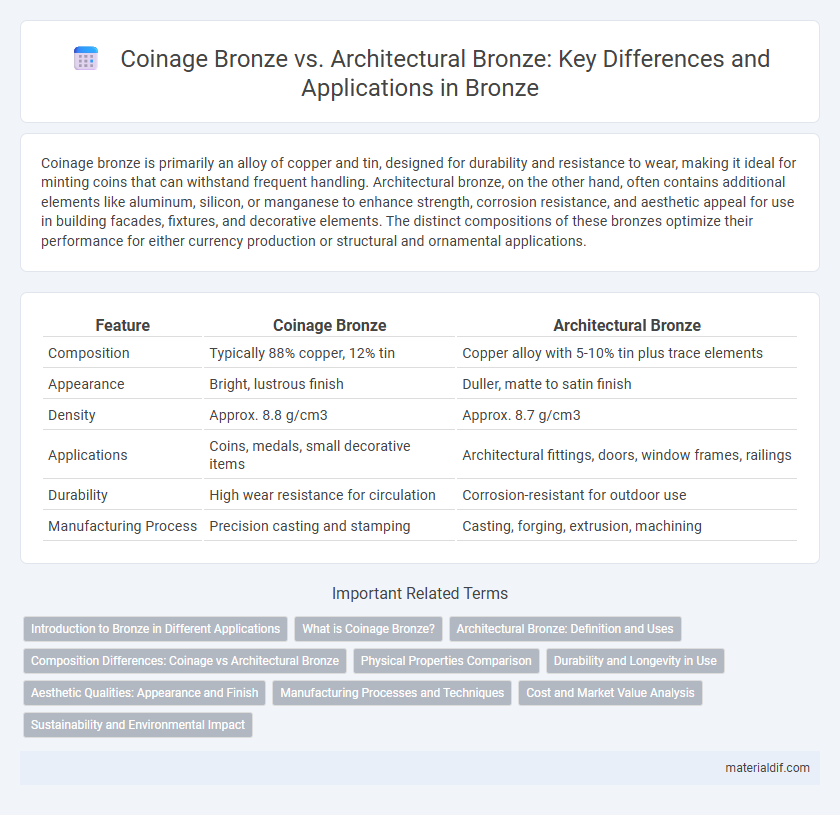

| Feature | Coinage Bronze | Architectural Bronze |

|---|---|---|

| Composition | Typically 88% copper, 12% tin | Copper alloy with 5-10% tin plus trace elements |

| Appearance | Bright, lustrous finish | Duller, matte to satin finish |

| Density | Approx. 8.8 g/cm3 | Approx. 8.7 g/cm3 |

| Applications | Coins, medals, small decorative items | Architectural fittings, doors, window frames, railings |

| Durability | High wear resistance for circulation | Corrosion-resistant for outdoor use |

| Manufacturing Process | Precision casting and stamping | Casting, forging, extrusion, machining |

Introduction to Bronze in Different Applications

Coinage bronze, typically composed of copper with tin and small amounts of zinc, is prized for its durability and resistance to corrosion, making it ideal for minting coins that withstand circulation. Architectural bronze, featuring a similar base but often enriched with aluminum or manganese, offers enhanced strength and a distinctive aesthetic suitable for building facades, decorative elements, and structural components. These variations in alloy composition and properties underline bronze's versatility across applications, balancing durability with visual appeal.

What is Coinage Bronze?

Coinage bronze is a specific alloy predominantly composed of copper, typically combined with about 5-10% tin and small amounts of zinc, designed for minting coins due to its durability and corrosion resistance. This type of bronze features a fine grain structure and a uniform color, making it ideal for detailed engraving and long-term preservation of coin imagery. Unlike architectural bronze, which is formulated for structural applications and often contains lead to improve machinability, coinage bronze prioritizes aesthetic qualities and wear resistance for circulation.

Architectural Bronze: Definition and Uses

Architectural bronze is a high-grade alloy primarily composed of copper and tin, renowned for its durability, corrosion resistance, and aesthetic appeal in construction. Used extensively in building facades, door frames, window sashes, and decorative hardware, this bronze variant enhances both structural integrity and visual elegance. Its ability to withstand environmental elements makes it ideal for long-lasting architectural applications, distinguishing it from coinage bronze which is tailored for minting coins.

Composition Differences: Coinage vs Architectural Bronze

Coinage bronze typically consists of approximately 88% copper and 12% tin, optimized for durability and corrosion resistance in circulating coins. Architectural bronze features a higher copper content, usually around 85-90%, combined with small amounts of zinc and lead to enhance machinability and weather resistance in building applications. The distinct elemental proportions between coinage and architectural bronze reflect their tailored mechanical properties and functional requirements.

Physical Properties Comparison

Coinage bronze typically consists of 88% copper and 12% tin, offering high hardness and excellent corrosion resistance, which makes it ideal for durable, detailed coins. Architectural bronze contains a higher copper content, around 90%, with small amounts of zinc and tin, resulting in enhanced tensile strength and weather resistance suited for structural applications. Both alloys exhibit good thermal conductivity and machinability, but architectural bronze provides greater mechanical stability under environmental stress compared to the more wear-resistant coinage bronze.

Durability and Longevity in Use

Coinage bronze, primarily composed of copper, tin, and occasionally zinc, offers exceptional durability and resistance to corrosion, making it ideal for long-term circulation as currency. Architectural bronze, with a similar composition but often enhanced with additional alloys like aluminum or nickel, provides superior longevity and structural strength suitable for building facades and decorative elements exposed to harsh environmental conditions. Both types exhibit excellent wear resistance, but architectural bronze typically withstands weathering and mechanical stress better due to its engineered alloy composition.

Aesthetic Qualities: Appearance and Finish

Coinage bronze typically features a fine, smooth finish with a warm, golden-brown hue that enhances detailed engravings and lends a consistent, polished look ideal for currency aesthetics. Architectural bronze exhibits a coarser texture with a natural patina that develops over time, offering a rugged yet elegant appearance suited to structural elements and ornamental facades. Both types emphasize durability and corrosion resistance while their distinct finishes cater to the aesthetic demands of precision minting versus enduring architectural design.

Manufacturing Processes and Techniques

Coinage bronze is primarily produced through precise casting and annealing processes to ensure consistent alloy composition and high durability required for minting coins, with a focus on uniform surface finish and fine detail reproduction. Architectural bronze involves advanced extrusion and rolling techniques combined with surface treatments such as patination to achieve corrosion resistance and aesthetic qualities suitable for building facades and decorative elements. Both types utilize controlled cooling and forging methods, but coinage bronze emphasizes metallurgical consistency, whereas architectural bronze prioritizes mechanical strength and weather resistance.

Cost and Market Value Analysis

Coinage bronze typically contains higher amounts of copper and tin, resulting in superior durability and a polished finish, which elevates its market value and cost compared to architectural bronze. Architectural bronze often incorporates recycled metals and lower-grade alloys to reduce expenses, making it a more cost-effective option for large-scale construction projects. Market analysis shows that coinage bronze commands premium pricing due to its use in collectible coins and currency, while architectural bronze benefits from broader availability and lower manufacturing costs.

Sustainability and Environmental Impact

Coinage bronze, primarily composed of copper and tin, is highly recyclable, reducing the need for virgin metal extraction and lowering its environmental footprint. Architectural bronze, a copper-zinc-tin alloy, offers durability and corrosion resistance, extending the lifespan of structures and minimizing resource consumption over time. Both alloys contribute to sustainability by enabling material reuse and supporting long-term environmental conservation in their respective applications.

Coinage Bronze vs Architectural Bronze Infographic

materialdif.com

materialdif.com