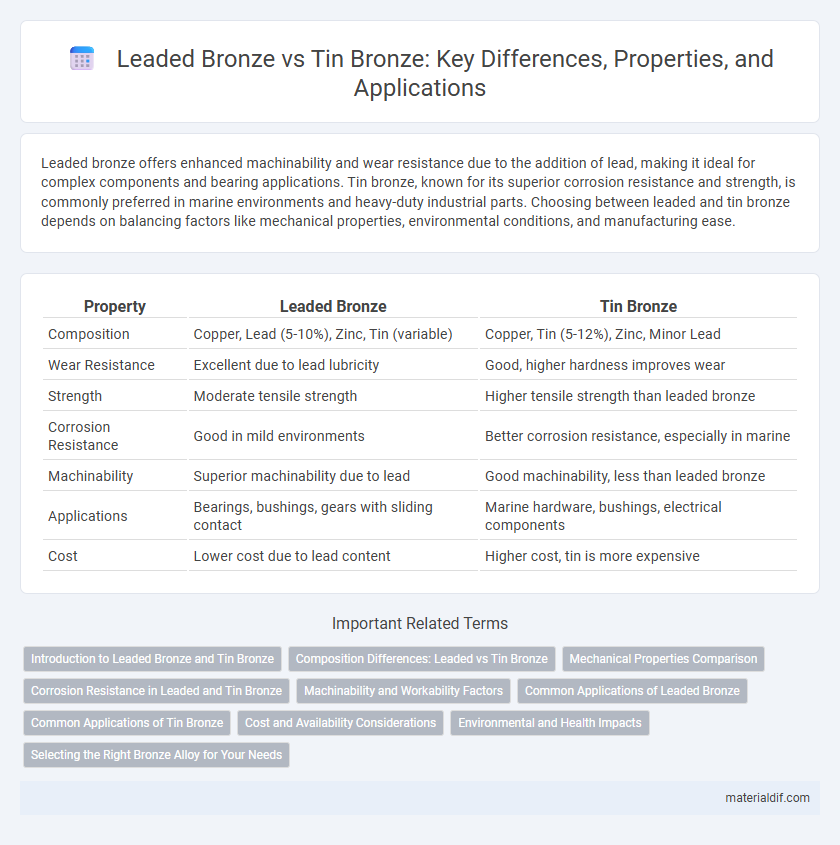

Leaded bronze offers enhanced machinability and wear resistance due to the addition of lead, making it ideal for complex components and bearing applications. Tin bronze, known for its superior corrosion resistance and strength, is commonly preferred in marine environments and heavy-duty industrial parts. Choosing between leaded and tin bronze depends on balancing factors like mechanical properties, environmental conditions, and manufacturing ease.

Table of Comparison

| Property | Leaded Bronze | Tin Bronze |

|---|---|---|

| Composition | Copper, Lead (5-10%), Zinc, Tin (variable) | Copper, Tin (5-12%), Zinc, Minor Lead |

| Wear Resistance | Excellent due to lead lubricity | Good, higher hardness improves wear |

| Strength | Moderate tensile strength | Higher tensile strength than leaded bronze |

| Corrosion Resistance | Good in mild environments | Better corrosion resistance, especially in marine |

| Machinability | Superior machinability due to lead | Good machinability, less than leaded bronze |

| Applications | Bearings, bushings, gears with sliding contact | Marine hardware, bushings, electrical components |

| Cost | Lower cost due to lead content | Higher cost, tin is more expensive |

Introduction to Leaded Bronze and Tin Bronze

Leaded bronze is an alloy of copper, tin, and a small percentage of lead, typically ranging from 5% to 10%, which enhances machinability and wear resistance in industrial applications. Tin bronze, primarily composed of copper and tin with tin content between 5% to 20%, is renowned for its superior corrosion resistance and strength, widely used in marine hardware and bearings. Both alloys serve distinct purposes: leaded bronze is favored for ease of casting and machining, while tin bronze is preferred for durability and environmental resistance.

Composition Differences: Leaded vs Tin Bronze

Leaded bronze contains 1-4% lead added to the copper-tin alloy, enhancing machinability and wear resistance, while tin bronze typically comprises 5-12% tin with no lead, providing superior corrosion resistance and strength. The lead in leaded bronze acts as a solid lubricant, improving casting and machining properties compared to tin bronze, which relies on higher tin content for hardness and tensile strength. This compositional difference dictates their industrial applications, with leaded bronze preferred in bearing and bushing components and tin bronze favored for marine and structural uses.

Mechanical Properties Comparison

Leaded bronze exhibits enhanced machinability and improved wear resistance due to the presence of lead, making it ideal for bearings and sliding applications. Tin bronze offers superior tensile strength and corrosion resistance, benefiting structural components and marine environments. Both alloys provide distinct mechanical properties, with leaded bronze favoring ease of machining and tin bronze emphasizing durability and strength.

Corrosion Resistance in Leaded and Tin Bronze

Leaded bronze exhibits superior corrosion resistance compared to tin bronze due to its lead content, which enhances machinability and reduces susceptibility to corrosion in marine and industrial environments. Tin bronze offers excellent corrosion resistance but is more prone to dezincification and stress corrosion cracking in chloride-rich environments. Both alloys are valuable, with leaded bronze preferred for applications requiring enhanced wear resistance and tin bronze favored where higher strength and corrosion resistance to seawater are critical.

Machinability and Workability Factors

Leaded bronze exhibits superior machinability due to the presence of lead, which acts as a lubricant during cutting processes, resulting in smoother finishes and longer tool life compared to tin bronze. Tin bronze, while offering excellent corrosion resistance and strength, has lower machinability but improved workability, making it more suitable for forging and casting applications. Choosing between leaded and tin bronze depends on whether enhanced machining efficiency or superior mechanical properties are the primary requirements.

Common Applications of Leaded Bronze

Leaded bronze is widely used in bearing and bushing applications due to its excellent machinability and enhanced wear resistance. Common industries employing leaded bronze include automotive, marine, and heavy machinery, where components like gears, valve guides, and pump parts benefit from its self-lubricating properties. The presence of lead in the alloy improves frictional performance, making leaded bronze ideal for high-load, low-speed environments.

Common Applications of Tin Bronze

Tin bronze is commonly used in applications requiring excellent corrosion resistance and good wear properties, such as bearings, bushings, and marine hardware. Its superior strength and fatigue resistance make it ideal for gears, springs, and electrical components. Unlike leaded bronze, tin bronze provides enhanced durability in high-stress environments without compromising machinability.

Cost and Availability Considerations

Leaded bronze generally costs more than tin bronze due to the higher expense and fluctuating availability of lead, which impacts overall production costs. Tin bronze benefits from more stable tin supplies, resulting in comparatively lower and more predictable material costs. Availability concerns for leaded bronze often lead manufacturers to prefer tin bronze for applications requiring consistent supply and budget control.

Environmental and Health Impacts

Leaded bronze contains lead, which poses significant environmental and health risks due to its toxicity, especially in manufacturing and disposal processes. Tin bronze, composed primarily of copper and tin, offers a safer alternative with lower toxicity and reduced environmental impact, making it preferable for applications requiring human exposure or eco-conscious considerations. The reduction of lead pollution and lead-related health hazards makes tin bronze a more sustainable and responsible choice in metal alloy use.

Selecting the Right Bronze Alloy for Your Needs

Leaded bronze offers improved machinability and wear resistance due to its lead content, making it ideal for applications requiring precision components and low friction. Tin bronze provides superior corrosion resistance and strength, which suits marine environments and structural parts exposed to stress. Selecting the right bronze alloy depends on prioritizing factors such as mechanical properties, environmental exposure, and manufacturing requirements to optimize performance and longevity.

Leaded Bronze vs Tin Bronze Infographic

materialdif.com

materialdif.com