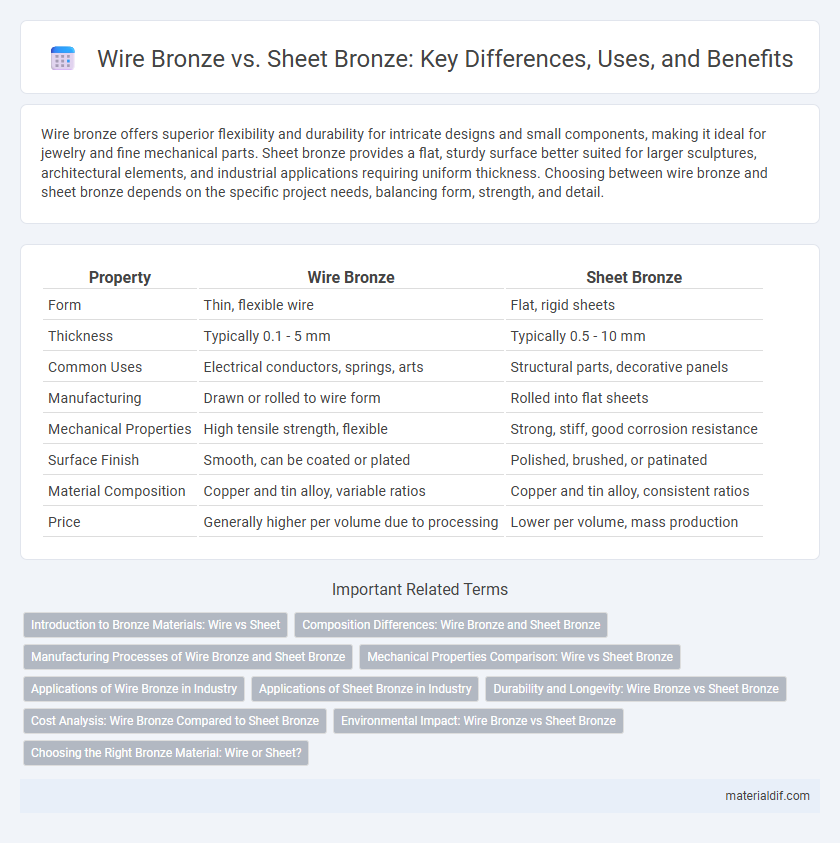

Wire bronze offers superior flexibility and durability for intricate designs and small components, making it ideal for jewelry and fine mechanical parts. Sheet bronze provides a flat, sturdy surface better suited for larger sculptures, architectural elements, and industrial applications requiring uniform thickness. Choosing between wire bronze and sheet bronze depends on the specific project needs, balancing form, strength, and detail.

Table of Comparison

| Property | Wire Bronze | Sheet Bronze |

|---|---|---|

| Form | Thin, flexible wire | Flat, rigid sheets |

| Thickness | Typically 0.1 - 5 mm | Typically 0.5 - 10 mm |

| Common Uses | Electrical conductors, springs, arts | Structural parts, decorative panels |

| Manufacturing | Drawn or rolled to wire form | Rolled into flat sheets |

| Mechanical Properties | High tensile strength, flexible | Strong, stiff, good corrosion resistance |

| Surface Finish | Smooth, can be coated or plated | Polished, brushed, or patinated |

| Material Composition | Copper and tin alloy, variable ratios | Copper and tin alloy, consistent ratios |

| Price | Generally higher per volume due to processing | Lower per volume, mass production |

Introduction to Bronze Materials: Wire vs Sheet

Bronze wire consists of thin, flexible strands ideal for electrical applications, jewelry making, and fine detailing due to its excellent conductivity and corrosion resistance. Sheet bronze, available in various thicknesses, offers durability and structural integrity for sculptures, architectural elements, and industrial components. The choice between wire and sheet bronze depends on the required form, strength, and application-specific properties.

Composition Differences: Wire Bronze and Sheet Bronze

Wire bronze typically contains a higher proportion of copper combined with tin and small amounts of phosphorus or zinc to enhance its strength and elasticity, making it suitable for applications requiring flexibility, such as springs and electrical contacts. Sheet bronze generally features a balanced composition of copper and tin with less emphasis on additives, optimizing its malleability and corrosion resistance for use in architectural elements, sculptures, and marine hardware. The distinct alloy variations between wire and sheet bronze directly influence their mechanical properties and ideal industrial uses.

Manufacturing Processes of Wire Bronze and Sheet Bronze

Wire bronze is produced through a drawing process where bronze rods are pulled through progressively smaller dies to achieve the desired diameter, enhancing tensile strength and flexibility. Sheet bronze is manufactured by casting or rolling bronze into thin, flat layers, followed by annealing to improve ductility and reduce internal stresses. Both processes require precise temperature control to maintain alloy composition and mechanical properties essential for diverse industrial applications.

Mechanical Properties Comparison: Wire vs Sheet Bronze

Wire bronze exhibits higher tensile strength and flexibility compared to sheet bronze, making it ideal for applications requiring durability under dynamic loads. Sheet bronze, however, offers better compressive strength and is more suitable for forming processes where rigidity and surface finish are critical. The distinct microstructures in wire and sheet bronze result in varied mechanical properties optimized for their respective industrial uses.

Applications of Wire Bronze in Industry

Wire bronze is widely used in industrial applications requiring excellent conductivity, corrosion resistance, and mechanical strength, such as electrical connectors, springs, and precision instruments. Its flexibility and tensile strength make it ideal for manufacturing wire forms, fine mesh screens, and complex winding components in motors and transformers. Compared to sheet bronze, wire bronze offers superior adaptability in applications demanding dynamic movement and intricate shapes.

Applications of Sheet Bronze in Industry

Sheet bronze is extensively used in industrial applications requiring corrosion resistance and aesthetic appeal, such as architectural cladding, sculptures, and manufacturing of musical instruments. Its superior malleability and uniform thickness make it ideal for precision components in aerospace, automotive trim, and electrical connectors. The durability and workability of sheet bronze enable its widespread use in decorative panels, marine hardware, and industrial machinery.

Durability and Longevity: Wire Bronze vs Sheet Bronze

Wire bronze exhibits superior durability due to its manufacturing process, which enhances tensile strength and resistance to fatigue, making it ideal for applications requiring flexible yet robust materials. Sheet bronze offers excellent longevity, particularly in corrosion resistance, as its dense, uniform surface minimizes environmental wear and maintains structural integrity over time. Comparing both, wire bronze outperforms in mechanical endurance and dynamic stress situations, while sheet bronze excels in static, protective uses where surface resilience is critical.

Cost Analysis: Wire Bronze Compared to Sheet Bronze

Wire bronze typically incurs higher manufacturing costs than sheet bronze due to more complex drawing and forming processes, leading to increased labor and equipment expenses. Sheet bronze benefits from more straightforward production methods like rolling and shearing, reducing overall material waste and enabling cost-effective large-scale fabrication. When evaluating cost analysis, wire bronze suits applications requiring precision and flexibility, while sheet bronze offers economic advantages for bulk and flat-form uses.

Environmental Impact: Wire Bronze vs Sheet Bronze

Wire bronze production involves higher energy consumption due to the drawing and annealing processes, resulting in increased carbon emissions compared to sheet bronze manufacturing, which primarily uses rolling techniques with lower energy demands. Sheet bronze's manufacturing process generates less metal waste and allows for more efficient recycling, minimizing environmental harm. Evaluating lifecycle assessments reveals that while both forms contain copper and tin, the form factor impacts overall environmental footprint more than the alloy composition.

Choosing the Right Bronze Material: Wire or Sheet?

Wire bronze offers superior flexibility and is ideal for applications requiring intricate bending or detailed craftsmanship, while sheet bronze provides a robust, flat surface suited for larger structural or decorative purposes. Selecting between wire or sheet bronze depends on the specific project requirements, including shape complexity, strength needs, and surface area. Understanding the unique mechanical properties and thickness variations of each form helps ensure optimal performance and durability in bronze fabrication.

Wire Bronze vs Sheet Bronze Infographic

materialdif.com

materialdif.com