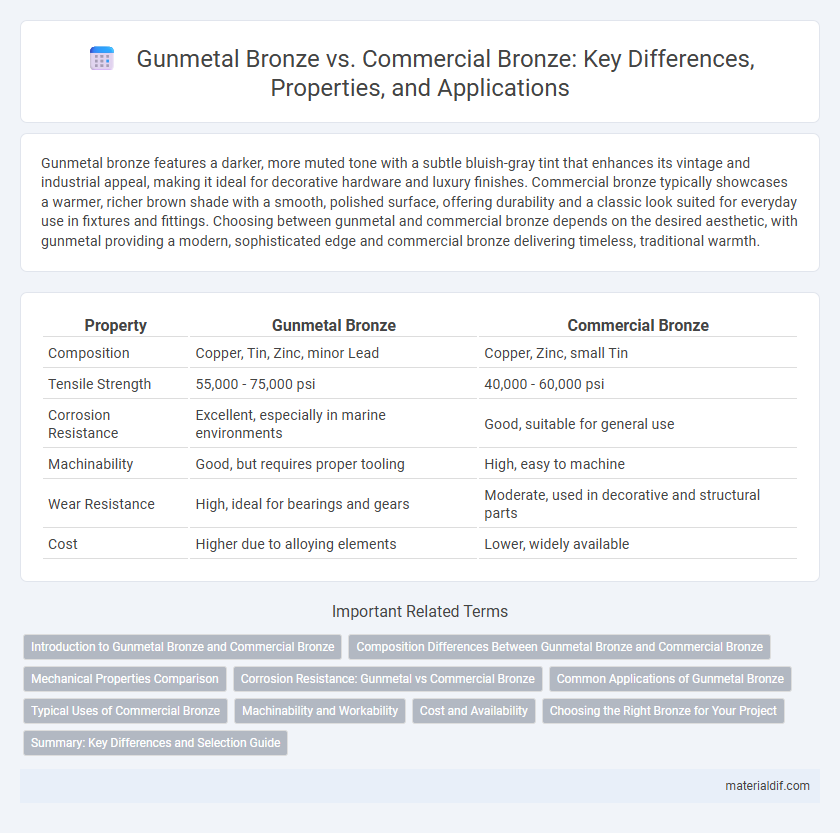

Gunmetal bronze features a darker, more muted tone with a subtle bluish-gray tint that enhances its vintage and industrial appeal, making it ideal for decorative hardware and luxury finishes. Commercial bronze typically showcases a warmer, richer brown shade with a smooth, polished surface, offering durability and a classic look suited for everyday use in fixtures and fittings. Choosing between gunmetal and commercial bronze depends on the desired aesthetic, with gunmetal providing a modern, sophisticated edge and commercial bronze delivering timeless, traditional warmth.

Table of Comparison

| Property | Gunmetal Bronze | Commercial Bronze |

|---|---|---|

| Composition | Copper, Tin, Zinc, minor Lead | Copper, Zinc, small Tin |

| Tensile Strength | 55,000 - 75,000 psi | 40,000 - 60,000 psi |

| Corrosion Resistance | Excellent, especially in marine environments | Good, suitable for general use |

| Machinability | Good, but requires proper tooling | High, easy to machine |

| Wear Resistance | High, ideal for bearings and gears | Moderate, used in decorative and structural parts |

| Cost | Higher due to alloying elements | Lower, widely available |

Introduction to Gunmetal Bronze and Commercial Bronze

Gunmetal bronze is a copper alloy primarily composed of copper, tin, and zinc, known for its excellent corrosion resistance and machinability, making it ideal for marine hardware and bearings. Commercial bronze typically contains a higher copper content with small amounts of lead and tin, offering good wear resistance and electrical conductivity, commonly used in electrical fittings and architectural applications. Both alloys provide distinct mechanical properties tailored to specific industrial uses, with gunmetal bronze favored for durability and commercial bronze for versatility.

Composition Differences Between Gunmetal Bronze and Commercial Bronze

Gunmetal bronze typically consists of approximately 88% copper, 10% tin, and 2% zinc, offering enhanced strength and corrosion resistance compared to commercial bronze. Commercial bronze, often composed of about 90% copper and 10% tin, has a simpler alloy structure resulting in lower machinability but higher malleability. The zinc content in gunmetal significantly improves hardness and wear resistance, making it suitable for heavy-duty applications unlike standard commercial bronze.

Mechanical Properties Comparison

Gunmetal bronze exhibits higher tensile strength and better corrosion resistance compared to commercial bronze, making it ideal for heavy-duty applications. Commercial bronze typically offers greater machinability and cost-effectiveness but has lower yield strength and hardness. These mechanical properties make gunmetal bronze preferable in marine environments, while commercial bronze suits general engineering purposes.

Corrosion Resistance: Gunmetal vs Commercial Bronze

Gunmetal bronze exhibits superior corrosion resistance compared to commercial bronze due to its higher copper and tin content combined with small amounts of zinc and lead, which enhance its durability in marine and industrial environments. Commercial bronze typically contains more impurities and less controlled alloying elements, making it more susceptible to oxidation and surface degradation when exposed to moisture and harsh chemicals. This resistance makes gunmetal bronze the preferred choice for applications requiring long-term exposure to corrosive elements, such as valves, bearings, and ship fittings.

Common Applications of Gunmetal Bronze

Gunmetal bronze, primarily composed of copper, tin, and zinc, is commonly used in applications requiring excellent corrosion resistance and mechanical strength, such as marine hardware, gears, and valve components. Its durability and resistance to steam and water make it ideal for casting intricate pumps and propellers in shipbuilding. Commercial bronze, often richer in copper and tin but with less zinc, finds broader use in architectural fittings and decorative items due to its appealing finish and moderate strength.

Typical Uses of Commercial Bronze

Commercial bronze is widely used in architectural applications, bearing decorative hardware, and marine fittings due to its excellent corrosion resistance and attractive finish. Its typical uses include door handles, locks, gears, and bearings, where strength and durability are essential. Unlike gunmetal bronze, commercial bronze offers greater versatility in general manufacturing and industrial components.

Machinability and Workability

Gunmetal bronze exhibits superior machinability due to its balanced composition of copper, tin, and zinc, allowing precise cutting and shaping with reduced tool wear. Commercial bronze, with higher copper content and less alloying, offers moderate machinability but excels in workability, making it ideal for forming and casting applications. The choice between gunmetal and commercial bronze depends on the specific requirements for machining precision versus ease of forming in manufacturing processes.

Cost and Availability

Gunmetal bronze generally incurs higher costs due to its specialized copper, tin, and zinc alloy composition, while commercial bronze is more affordable owing to its widely accessible and simpler alloy mix. Availability of commercial bronze is greater, with easier sourcing from numerous suppliers, whereas gunmetal bronze is less common, often requiring custom orders or specialty manufacturers. Cost efficiency and accessibility make commercial bronze the preferred choice for most industrial and decorative applications.

Choosing the Right Bronze for Your Project

Gunmetal bronze, known for its superior corrosion resistance and higher strength, suits marine and industrial applications requiring durability under stress. Commercial bronze, often alloyed with more zinc, offers excellent machinability and cost-effectiveness, ideal for decorative or light-duty uses. Selecting the right bronze depends on balancing mechanical properties, environmental exposure, and budget constraints to meet your project's specific performance criteria.

Summary: Key Differences and Selection Guide

Gunmetal bronze contains a higher percentage of tin and often includes zinc and lead, resulting in enhanced corrosion resistance and superior machinability compared to commercial bronze. Commercial bronze typically consists mainly of copper and tin, offering good strength and wear resistance suitable for general applications. Select gunmetal bronze for marine or bearing uses requiring durability and corrosion resistance, while commercial bronze is ideal for standard industrial components needing balanced strength and cost-efficiency.

Gunmetal Bronze vs Commercial Bronze Infographic

materialdif.com

materialdif.com