Bronze sheets offer a flat, uniform surface ideal for applications requiring precise thickness and easy cutting, making them perfect for decorative panels and architectural elements. Bronze rods provide strength and durability in a cylindrical form, suitable for machining into shafts, pins, and fasteners where torsional resistance is essential. Choosing between bronze sheet and bronze rod depends on the specific mechanical and structural requirements of the project.

Table of Comparison

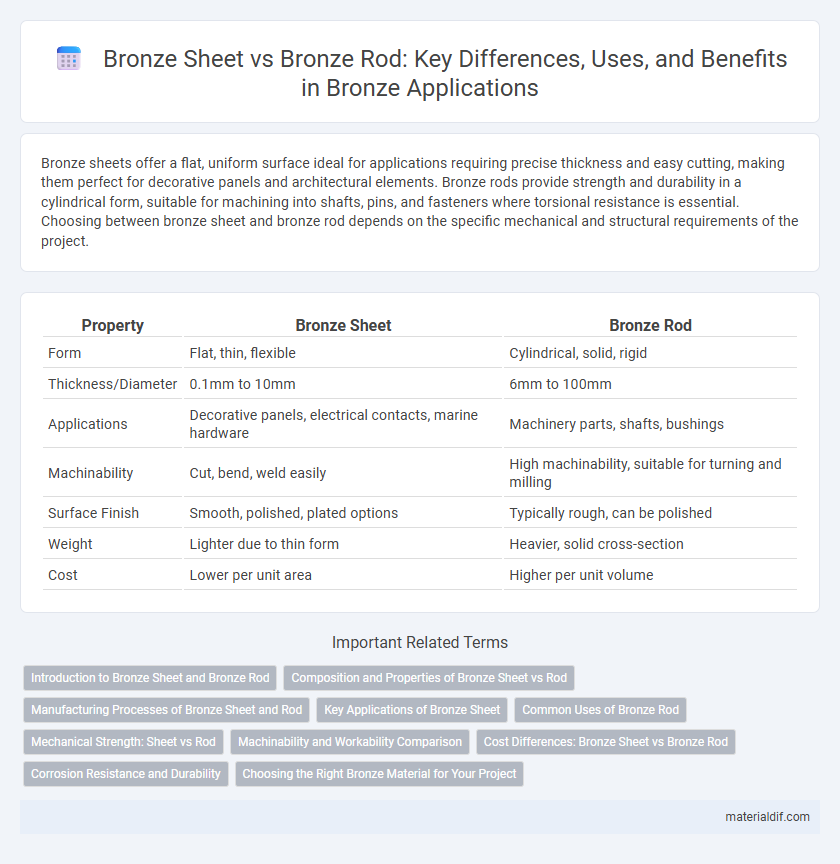

| Property | Bronze Sheet | Bronze Rod |

|---|---|---|

| Form | Flat, thin, flexible | Cylindrical, solid, rigid |

| Thickness/Diameter | 0.1mm to 10mm | 6mm to 100mm |

| Applications | Decorative panels, electrical contacts, marine hardware | Machinery parts, shafts, bushings |

| Machinability | Cut, bend, weld easily | High machinability, suitable for turning and milling |

| Surface Finish | Smooth, polished, plated options | Typically rough, can be polished |

| Weight | Lighter due to thin form | Heavier, solid cross-section |

| Cost | Lower per unit area | Higher per unit volume |

Introduction to Bronze Sheet and Bronze Rod

Bronze sheets offer a flat, uniform surface ideal for applications requiring ease of cutting, shaping, and layering, commonly used in architectural panels and decorative arts. Bronze rods provide a solid, cylindrical form preferred for mechanical parts, fasteners, and machining components where tensile strength and durability are essential. Both materials leverage bronze's corrosion resistance and thermal conductivity but serve distinct structural and functional roles in manufacturing and industrial design.

Composition and Properties of Bronze Sheet vs Rod

Bronze sheets and rods both consist primarily of copper alloyed with tin, typically ranging from 5% to 20% tin, but sheets often include additional elements like aluminum or phosphorus to enhance surface durability and corrosion resistance. The flat structure of bronze sheets provides superior tensile strength and flexibility, making them ideal for applications requiring malleability and wear resistance, while bronze rods offer higher structural rigidity and impact resistance due to their solid cylindrical form. Both forms exhibit excellent thermal conductivity, corrosion resistance, and antimicrobial properties, but the mechanical performance varies with the specific alloy composition tailored for sheet or rod manufacturing.

Manufacturing Processes of Bronze Sheet and Rod

Bronze sheets are manufactured through processes such as rolling and annealing, which involve heating the metal to increase its ductility before flattening it into thin, uniform layers. Bronze rods are produced using extrusion or casting methods, where molten bronze is forced through a die or poured into molds to form cylindrical shapes. The choice of manufacturing process significantly affects the microstructure, mechanical properties, and surface finish of the final bronze product.

Key Applications of Bronze Sheet

Bronze sheets are primarily used in architectural applications, marine equipment, and decorative art due to their excellent corrosion resistance and malleability. They provide an ideal surface for engraving and embossing, making them popular in signage, plaques, and ornamental panels. Unlike bronze rods, which are favored for structural components and mechanical parts, bronze sheets excel in applications requiring thin, uniform thickness and aesthetic appeal.

Common Uses of Bronze Rod

Bronze rods are commonly used in manufacturing precision components, such as bushings, bearings, and valves, due to their excellent corrosion resistance and high strength. They are favored in electrical connectors and marine hardware because of their superior conductivity and durability in harsh environments. In contrast, bronze sheets are typically employed for decorative applications, architectural purposes, and hardware fabrication.

Mechanical Strength: Sheet vs Rod

Bronze rods typically exhibit higher mechanical strength compared to bronze sheets due to their solid, cylindrical form which enhances load-bearing capacity and resistance to deformation under stress. The manufacturing process of rods often involves cold working or extrusion, increasing tensile strength and hardness relative to the more flexible and thinner bronze sheets. Sheets provide better formability and are suited for applications requiring moderate strength and easy shaping, whereas rods are preferred for structural components needing maximum durability and mechanical robustness.

Machinability and Workability Comparison

Bronze sheets offer superior machinability due to their uniform thickness and smooth surface, making them ideal for precise cutting and shaping in industrial applications. Bronze rods provide enhanced workability because their cylindrical form allows easy forging and bending without compromising structural integrity. Selecting between bronze sheet and rod depends on the specific machining processes and the desired flexibility in fabrication.

Cost Differences: Bronze Sheet vs Bronze Rod

Bronze sheets generally have a lower cost per pound compared to bronze rods due to simpler manufacturing processes and material efficiency. The production of bronze rods involves extrusion or drawing methods that increase labor and energy expenses, resulting in higher prices. Cost variations also depend on thickness and alloy composition, with bronze sheets offering more economical options for large surface applications.

Corrosion Resistance and Durability

Bronze sheets exhibit superior corrosion resistance compared to bronze rods due to their flat surface area, which allows for more uniform protective patina development, enhancing durability in marine and industrial environments. Bronze rods, while also corrosion-resistant, are typically used in applications requiring mechanical strength and wear resistance, where their dimensional stability under stress contributes to long-term durability. The choice between bronze sheet and rod depends on the specific application requirements, with sheets favored for corrosion protection and rods preferred for structural integrity.

Choosing the Right Bronze Material for Your Project

Bronze sheets offer flat, uniform surfaces ideal for decorative panels and wear-resistant applications, while bronze rods provide versatile, cylindrical forms suited for machining and structural components. Selecting the right bronze material hinges on project requirements such as dimensional precision, mechanical strength, and corrosion resistance. Consider factors like thickness, alloy composition, and fabrication methods to optimize performance and durability in your specific application.

Bronze Sheet vs Bronze Rod Infographic

materialdif.com

materialdif.com