Machinable bronze offers excellent ease of fabrication, making it ideal for components requiring precise shaping and smooth finishes, while high-strength bronze provides superior durability and resistance to wear under heavy mechanical stress. Machinable bronze typically contains additives that enhance its ability to be cut and shaped efficiently without sacrificing corrosion resistance. High-strength bronze alloys, often reinforced with elements like aluminum or nickel, deliver exceptional performance in applications demanding high load-bearing capacity and toughness.

Table of Comparison

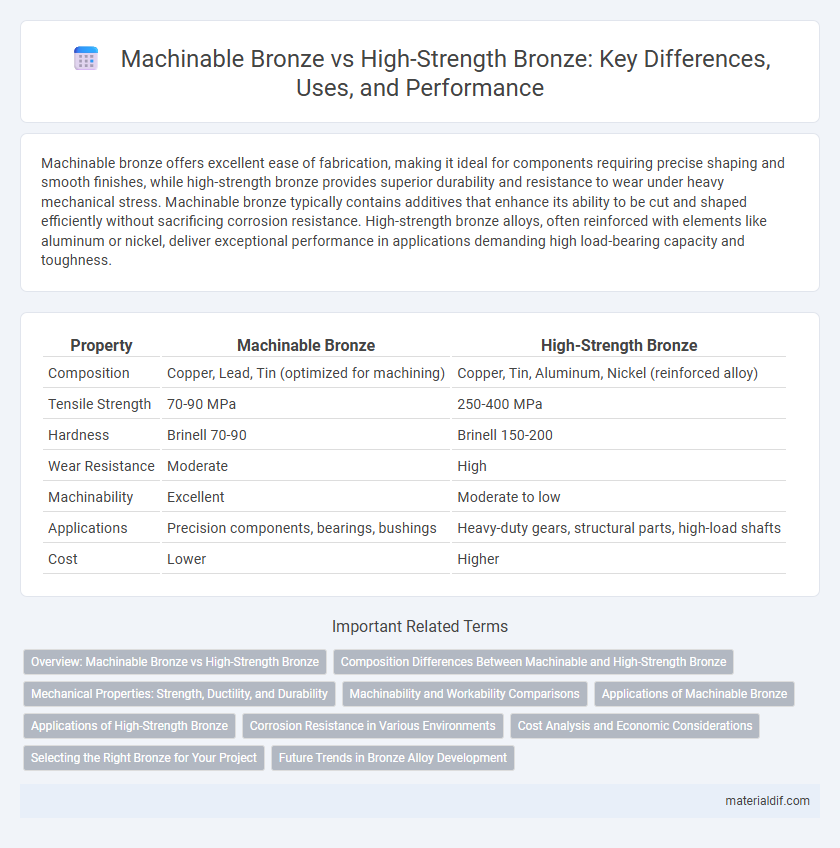

| Property | Machinable Bronze | High-Strength Bronze |

|---|---|---|

| Composition | Copper, Lead, Tin (optimized for machining) | Copper, Tin, Aluminum, Nickel (reinforced alloy) |

| Tensile Strength | 70-90 MPa | 250-400 MPa |

| Hardness | Brinell 70-90 | Brinell 150-200 |

| Wear Resistance | Moderate | High |

| Machinability | Excellent | Moderate to low |

| Applications | Precision components, bearings, bushings | Heavy-duty gears, structural parts, high-load shafts |

| Cost | Lower | Higher |

Overview: Machinable Bronze vs High-Strength Bronze

Machinable bronze is engineered for ease of cutting and shaping, featuring lower hardness and exceptional machinability, making it ideal for intricate components and rapid production. High-strength bronze alloys offer superior tensile strength, enhanced wear resistance, and excellent load-bearing capacity, suitable for demanding industrial applications like heavy machinery and structural parts. Selecting between machinable bronze and high-strength bronze depends on balancing manufacturing efficiency against performance requirements in specific environmental conditions.

Composition Differences Between Machinable and High-Strength Bronze

Machinable bronze typically contains higher lead content, around 8-12%, enhancing its cutting performance and ease of machining. In contrast, high-strength bronze alloys prioritize copper combined with elements like tin, aluminum, or nickel, which increase tensile strength and wear resistance but reduce machinability. The difference in composition directly impacts their mechanical properties and suitability for specific industrial applications.

Mechanical Properties: Strength, Ductility, and Durability

Machinable bronze offers moderate strength and excellent ductility, making it ideal for precision components requiring ease of machining and resistance to deformation. High-strength bronze exhibits superior tensile and yield strength, ensuring enhanced load-bearing capacity and exceptional durability under demanding conditions. While machinable bronze prioritizes workability, high-strength bronze provides greater resistance to wear and fatigue, extending the lifespan of heavy-duty mechanical parts.

Machinability and Workability Comparisons

Machinable bronze offers superior workability due to its lower strength and softer composition, making it ideal for precision machining and intricate component fabrication. In contrast, high-strength bronze exhibits enhanced mechanical properties and durability but presents challenges in machining, often requiring specialized tools and slower processing speeds. The trade-off between machinability and strength is critical in selecting the appropriate bronze alloy for applications ranging from complex fittings to heavy-duty structural parts.

Applications of Machinable Bronze

Machinable bronze is widely used in manufacturing precision components such as bearings, bushings, and gears due to its excellent machinability and wear resistance. Its applications extend to electrical connectors and fittings where dimensional accuracy and good conductivity are essential. This bronze type is preferred in industries requiring complex shapes and fine tolerances, including aerospace, automotive, and plumbing.

Applications of High-Strength Bronze

High-strength bronze is extensively used in heavy-load bearing applications such as marine hardware, aerospace components, and heavy machinery due to its superior tensile strength and wear resistance. Its enhanced mechanical properties allow for durable performance in environments involving high stress, friction, and corrosion. These capabilities make it ideal for high-performance bearings, gears, and structural parts in demanding industrial settings.

Corrosion Resistance in Various Environments

Machinable bronze exhibits moderate corrosion resistance suitable for general applications but may degrade faster in highly acidic or marine environments. High-strength bronze alloys offer superior corrosion resistance due to enhanced alloying elements like aluminum and nickel, making them ideal for harsh industrial and marine conditions. Selecting the appropriate bronze depends on environmental exposure, balancing machinability and long-term durability against corrosion.

Cost Analysis and Economic Considerations

Machinable bronze offers lower production costs due to its ease of fabrication and reduced tool wear, making it ideal for complex parts with tight tolerances. High-strength bronze presents higher material and processing expenses but delivers superior durability and load-bearing capacity, which can reduce long-term maintenance and replacement costs. Selecting between these bronzes requires balancing initial investment against lifecycle performance and application-specific economic benefits.

Selecting the Right Bronze for Your Project

Machinable bronze offers excellent ease of fabrication, making it ideal for precision components requiring intricate shapes and tight tolerances. High-strength bronze, featuring superior tensile strength and wear resistance, suits heavy-load applications and environments with high friction or stress. Selecting the right bronze depends on balancing machinability with mechanical demands, ensuring optimal performance and longevity for your specific project.

Future Trends in Bronze Alloy Development

Machinable bronze alloys continue to evolve with enhanced wear resistance and improved thermal conductivity, meeting the demands of precision manufacturing and automated production. High-strength bronze formulations are increasingly incorporating advanced alloying elements such as aluminum and nickel to achieve superior tensile strength and corrosion resistance in extreme environments. Future trends emphasize sustainable alloy compositions and additive manufacturing compatibility, driving innovation in aerospace, automotive, and industrial applications.

Machinable Bronze vs High-Strength Bronze Infographic

materialdif.com

materialdif.com