Oil-impregnated bronze offers superior self-lubrication, reducing friction and wear in high-load applications without the need for external lubrication. Dry bronze, while maintenance-free and resistant to corrosion, typically experiences higher friction and may wear faster under heavy or continuous use. Choosing between oil-impregnated and dry bronze depends on the specific operational demands, including load, speed, and environmental conditions.

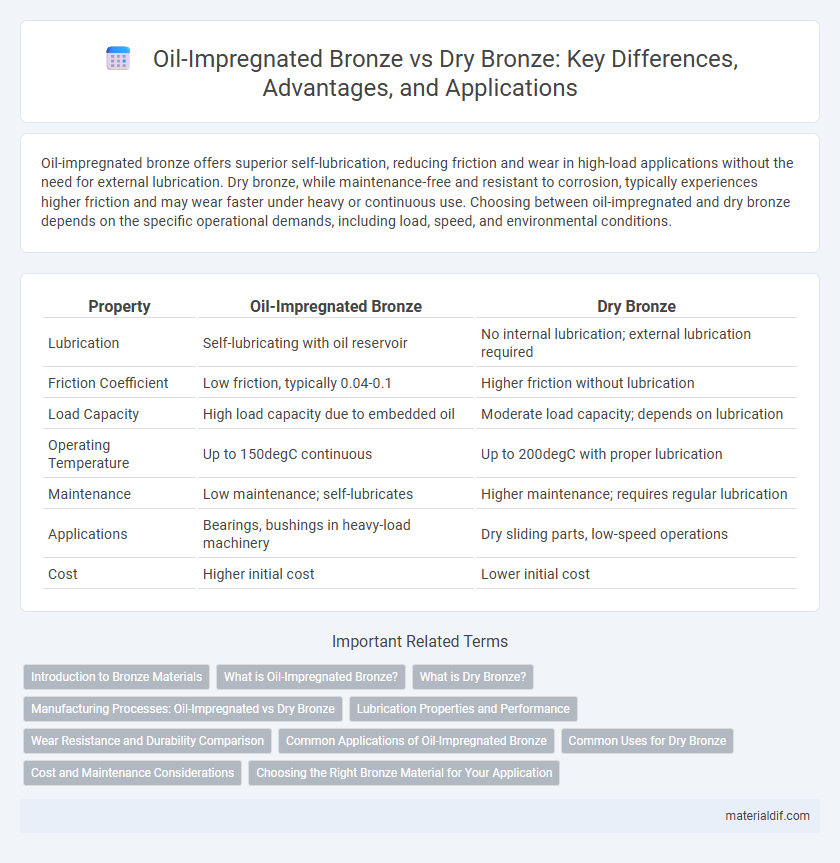

Table of Comparison

| Property | Oil-Impregnated Bronze | Dry Bronze |

|---|---|---|

| Lubrication | Self-lubricating with oil reservoir | No internal lubrication; external lubrication required |

| Friction Coefficient | Low friction, typically 0.04-0.1 | Higher friction without lubrication |

| Load Capacity | High load capacity due to embedded oil | Moderate load capacity; depends on lubrication |

| Operating Temperature | Up to 150degC continuous | Up to 200degC with proper lubrication |

| Maintenance | Low maintenance; self-lubricates | Higher maintenance; requires regular lubrication |

| Applications | Bearings, bushings in heavy-load machinery | Dry sliding parts, low-speed operations |

| Cost | Higher initial cost | Lower initial cost |

Introduction to Bronze Materials

Oil-impregnated bronze offers enhanced self-lubricating properties by incorporating lubricant within its porous structure, improving wear resistance and reducing friction in high-load applications. Dry bronze, in contrast, lacks inherent lubrication, requiring external lubrication for optimal performance, making it suitable for lower-load or maintenance-friendly environments. Both materials capitalize on bronze's alloy composition, primarily copper and tin, providing excellent corrosion resistance and mechanical strength essential for various industrial uses.

What is Oil-Impregnated Bronze?

Oil-impregnated bronze is a self-lubricating bearing material composed of a porous bronze matrix impregnated with lubricant oil, providing continuous lubrication during operation. This type of bronze reduces friction and wear in applications where external lubrication is difficult or impossible, enhancing the lifespan and performance of mechanical components. Unlike dry bronze, which requires regular external lubrication, oil-impregnated bronze maintains optimal lubrication internally, improving reliability and reducing maintenance needs.

What is Dry Bronze?

Dry bronze is a type of bronze alloy used in bearing applications without any oil or lubricant impregnation, offering maintenance-free operation. It provides excellent wear resistance and durability in low-load, low-speed conditions where lubrication is impractical or undesirable. Its solid, dry surface reduces the risk of contamination and simplifies mechanical design compared to oil-impregnated bronze.

Manufacturing Processes: Oil-Impregnated vs Dry Bronze

Oil-impregnated bronze is manufactured through a sintering process that compacts bronze powder into a porous structure subsequently saturated with lubricating oil, enhancing friction reduction and wear resistance. Dry bronze, by contrast, is typically produced via casting or machining from solid bronze billets, resulting in a denser, non-porous material lacking internal lubrication properties. The sintering and oil impregnation method used for oil-impregnated bronze provides superior self-lubricating capabilities compared to the more conventional manufacturing routes utilized for dry bronze components.

Lubrication Properties and Performance

Oil-impregnated bronze offers superior self-lubrication due to its porous structure saturated with oil, providing continuous lubrication and reducing wear during operation. Dry bronze relies on external lubricants, which may lead to increased friction and maintenance requirements under high load or speed conditions. The enhanced lubrication properties of oil-impregnated bronze result in improved performance, extended component lifespan, and reduced downtime compared to dry bronze applications.

Wear Resistance and Durability Comparison

Oil-impregnated bronze offers significantly enhanced wear resistance and durability compared to dry bronze due to its self-lubricating properties, which reduce friction and prevent metal-to-metal contact. The embedded oil within porous bronze structures ensures continuous lubrication, extending component lifespan and improving performance under high-load, high-speed conditions. Dry bronze, while harder and more rigid, experiences greater wear and requires frequent maintenance, limiting its suitability for dynamic or heavy-duty applications.

Common Applications of Oil-Impregnated Bronze

Oil-impregnated bronze is widely used in applications requiring self-lubrication, such as bushings, bearings, and gears in heavy machinery, automotive components, and industrial equipment. Its ability to reduce friction and wear without external lubrication makes it ideal for high-load and low-speed conditions in conveyor systems, pumps, and compressors. This material enhances equipment lifespan and reliability in environments where maintenance access is limited and continuous lubrication is impractical.

Common Uses for Dry Bronze

Dry bronze is commonly used in applications where low friction and minimal maintenance are essential, such as bushings, bearings, and wear plates in industrial machinery. It excels in environments with light to moderate loads and where lubrication is not feasible or desired. Typical sectors utilizing dry bronze include automotive, aerospace, and agricultural equipment manufacturing.

Cost and Maintenance Considerations

Oil-impregnated bronze offers lower maintenance costs due to its self-lubricating properties, reducing the need for frequent lubrication compared to dry bronze. While the initial cost of oil-impregnated bronze is higher, long-term savings are realized through extended service life and decreased downtime. Dry bronze requires regular lubrication and higher maintenance efforts, increasing overall operational expenses despite its lower upfront price.

Choosing the Right Bronze Material for Your Application

Oil-impregnated bronze offers superior self-lubrication properties, reducing friction and wear in high-load, low-speed applications. Dry bronze, while requiring external lubrication, provides excellent strength and corrosion resistance for environments where oil contamination is undesirable. Choosing the right bronze material depends on operational conditions, maintenance capabilities, and performance requirements to ensure optimal durability and efficiency.

Oil-Impregnated Bronze vs Dry Bronze Infographic

materialdif.com

materialdif.com