Bronze bar stock is a solid, dense material ideal for machining parts requiring strength and durability, while bronze tubing offers a hollow structure suitable for applications where weight reduction and fluid flow are essential. Bar stock is often used in custom components or bearings, providing excellent wear resistance, whereas tubing is favored for plumbing or heat exchange systems due to its corrosion resistance and ease of fabrication. Choosing between bronze bar stock and bronze tubing depends on whether solid mass or hollow form better meets the mechanical and design requirements of the project.

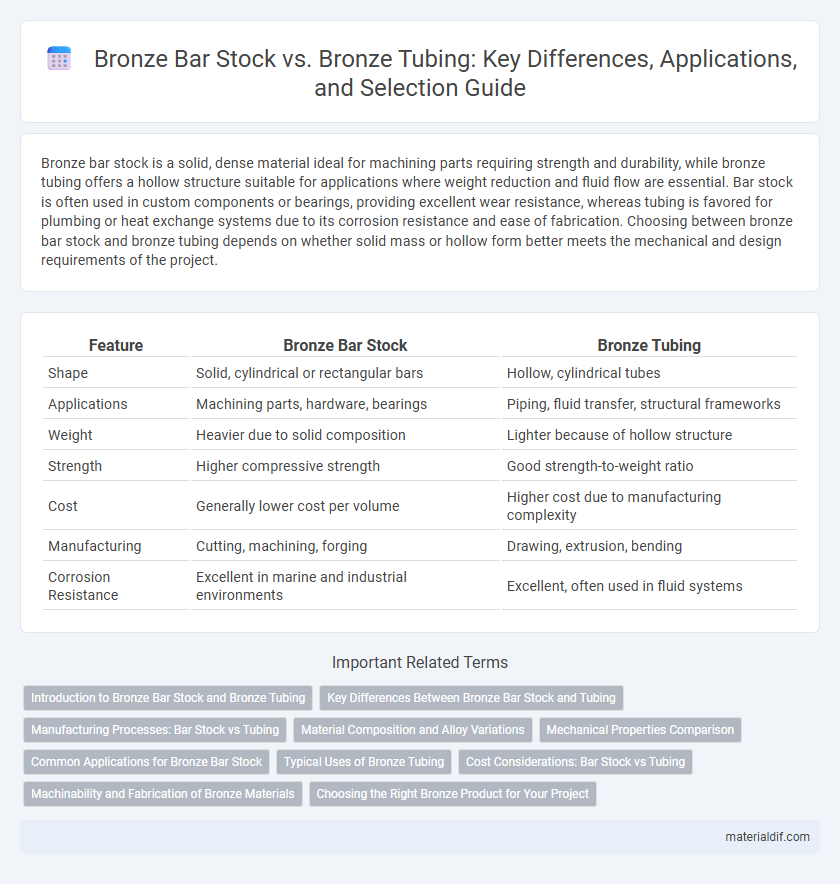

Table of Comparison

| Feature | Bronze Bar Stock | Bronze Tubing |

|---|---|---|

| Shape | Solid, cylindrical or rectangular bars | Hollow, cylindrical tubes |

| Applications | Machining parts, hardware, bearings | Piping, fluid transfer, structural frameworks |

| Weight | Heavier due to solid composition | Lighter because of hollow structure |

| Strength | Higher compressive strength | Good strength-to-weight ratio |

| Cost | Generally lower cost per volume | Higher cost due to manufacturing complexity |

| Manufacturing | Cutting, machining, forging | Drawing, extrusion, bending |

| Corrosion Resistance | Excellent in marine and industrial environments | Excellent, often used in fluid systems |

Introduction to Bronze Bar Stock and Bronze Tubing

Bronze bar stock refers to solid, cylindrical or rectangular rods made from bronze alloy, commonly used in machining and manufacturing for components requiring high strength and corrosion resistance. Bronze tubing, on the other hand, consists of hollow cylindrical sections ideal for applications such as fluid transfer, heat exchange, and structural support where weight reduction is critical. Both forms utilize bronze's excellent wear resistance and thermal conductivity, but bar stock prioritizes machinability and strength, while tubing emphasizes fluid dynamics and lightweight construction.

Key Differences Between Bronze Bar Stock and Tubing

Bronze bar stock is a solid, rectangular or cylindrical piece of metal used for machining into various components, whereas bronze tubing is hollow, designed for fluid transport or decorative applications. The key differences include the structural form, with bar stock offering greater strength and machinability, while tubing provides lighter weight and fluid flow capabilities. Material properties like corrosion resistance and alloy composition remain similar, but the choice depends on whether solid mass or hollow design is required for the application.

Manufacturing Processes: Bar Stock vs Tubing

Bronze bar stock is typically produced through continuous casting and extrusion processes, resulting in solid, uniform billets that are later machined or fabricated into components. Bronze tubing, conversely, is manufactured using seamless or welded tube production methods, including rotary piercing or drawing for seamless tubes and rolling or extrusion followed by welding for tube forms. These distinct manufacturing techniques influence the mechanical properties, dimensions, and potential applications of bronze bar stock and tubing in industrial and architectural uses.

Material Composition and Alloy Variations

Bronze bar stock typically contains higher concentrations of copper combined with varying amounts of tin, aluminum, or phosphorus to enhance strength and corrosion resistance, making it ideal for machining applications. Bronze tubing often incorporates alloy variations such as manganese or silicon bronze, which improve flexibility and wear resistance, suitable for fluid transport systems. Material composition differences between solid bar stock and hollow tubing influence mechanical properties, impacting their respective industrial uses.

Mechanical Properties Comparison

Bronze bar stock generally offers higher tensile strength and better wear resistance compared to bronze tubing, making it ideal for heavy-duty mechanical applications. Bronze tubing, while slightly lower in strength, provides superior flexibility and corrosion resistance, which is advantageous in fluid transport and marine environments. The choice between these forms depends on the specific mechanical property priorities such as load-bearing capacity versus adaptability and environmental resilience.

Common Applications for Bronze Bar Stock

Bronze bar stock is widely used in manufacturing heavy-duty components such as bearings, bushings, and gears due to its excellent strength and wear resistance. Common applications include machine parts, marine hardware, and architectural fittings where durability and corrosion resistance are critical. Compared to bronze tubing, bar stock allows for more precise machining and versatility in creating solid structural pieces for industrial use.

Typical Uses of Bronze Tubing

Bronze tubing is commonly used in marine hardware, hydraulic systems, and architectural applications due to its excellent corrosion resistance and strength. Its hollow cylindrical shape allows for fluid transport and mechanical support in plumbing and heat exchangers. Unlike solid bronze bar stock, bronze tubing provides a lightweight and versatile solution for fluid conveyance and structural purposes.

Cost Considerations: Bar Stock vs Tubing

Bronze bar stock generally costs less than bronze tubing due to simpler manufacturing processes and lower material complexity, making it a cost-effective choice for projects requiring solid shapes. Bronze tubing involves additional extrusion and forming steps, increasing production expenses and resulting in higher unit prices. When budgeting for bronze components, factoring in machining time and material waste is essential, as bar stock often offers greater versatility with less scrap compared to tubing.

Machinability and Fabrication of Bronze Materials

Bronze bar stock offers superior machinability compared to bronze tubing due to its solid, uniform structure that allows precise cutting and shaping with minimal tool wear. In contrast, bronze tubing often requires specialized fabrication techniques such as bending and welding, which can be more complex but enable lightweight and hollow designs ideal for fluid transport. Selecting between bronze bar stock and tubing depends on the application's demand for mechanical strength, ease of machining, and fabrication flexibility.

Choosing the Right Bronze Product for Your Project

Selecting the right bronze product depends on the specific application requirements such as strength, machinability, and corrosion resistance. Bronze bar stock offers solid, versatile material ideal for custom machining and heavy-duty components, while bronze tubing provides lightweight, hollow structures suitable for fluid transport and decorative purposes. Evaluate factors like mechanical stress, dimensional accuracy, and cost to ensure optimal performance and longevity in your project.

Bronze Bar Stock vs Bronze Tubing Infographic

materialdif.com

materialdif.com