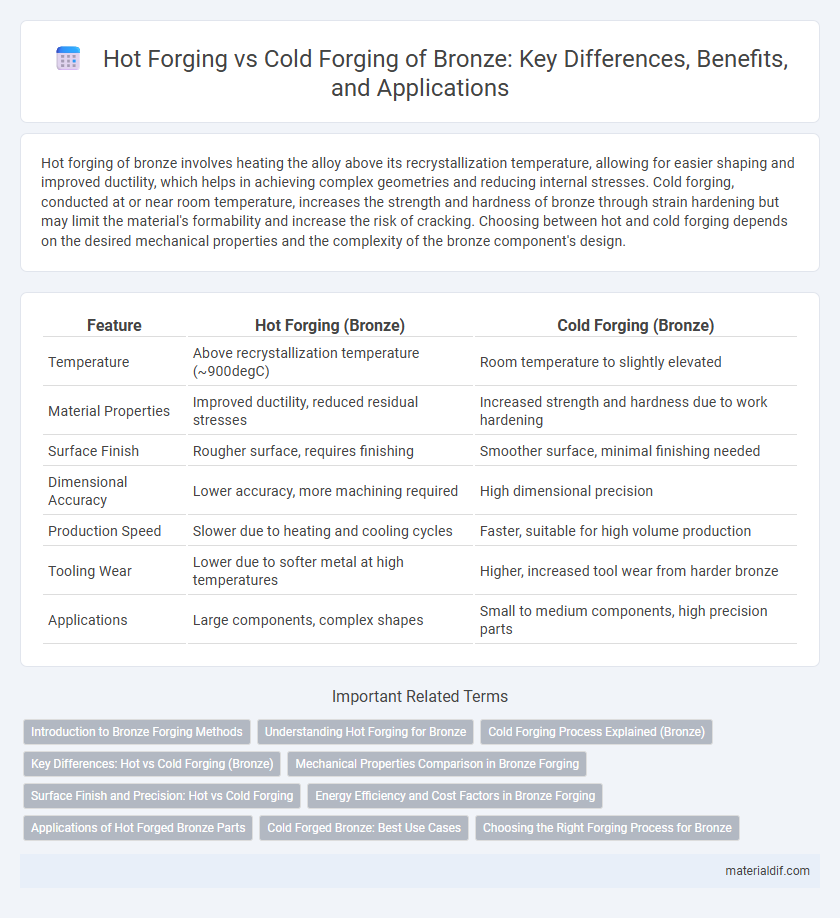

Hot forging of bronze involves heating the alloy above its recrystallization temperature, allowing for easier shaping and improved ductility, which helps in achieving complex geometries and reducing internal stresses. Cold forging, conducted at or near room temperature, increases the strength and hardness of bronze through strain hardening but may limit the material's formability and increase the risk of cracking. Choosing between hot and cold forging depends on the desired mechanical properties and the complexity of the bronze component's design.

Table of Comparison

| Feature | Hot Forging (Bronze) | Cold Forging (Bronze) |

|---|---|---|

| Temperature | Above recrystallization temperature (~900degC) | Room temperature to slightly elevated |

| Material Properties | Improved ductility, reduced residual stresses | Increased strength and hardness due to work hardening |

| Surface Finish | Rougher surface, requires finishing | Smoother surface, minimal finishing needed |

| Dimensional Accuracy | Lower accuracy, more machining required | High dimensional precision |

| Production Speed | Slower due to heating and cooling cycles | Faster, suitable for high volume production |

| Tooling Wear | Lower due to softer metal at high temperatures | Higher, increased tool wear from harder bronze |

| Applications | Large components, complex shapes | Small to medium components, high precision parts |

Introduction to Bronze Forging Methods

Bronze forging involves shaping the alloy through two primary methods: hot forging and cold forging, each affecting the metal's microstructure and mechanical properties differently. Hot forging heats bronze above its recrystallization temperature, enhancing ductility and allowing complex shapes with reduced risk of cracking, while cold forging retains higher strength and surface finish by deformation at room temperature. Selecting the appropriate method depends on the desired balance between mechanical strength, dimensional accuracy, and production efficiency in bronze components.

Understanding Hot Forging for Bronze

Hot forging of bronze involves heating the metal above its recrystallization temperature, typically between 700degC and 900degC, to enhance its ductility and reduce the risk of cracking during deformation. This process refines the grain structure, resulting in improved mechanical properties such as increased strength and toughness compared to cold forging. Hot forging is essential for shaping complex bronze components that require superior performance in applications like bearings, bushings, and sculptures.

Cold Forging Process Explained (Bronze)

Cold forging of bronze involves shaping the metal at or near room temperature, which enhances its strength and surface finish due to strain hardening. This process improves dimensional accuracy and results in superior mechanical properties compared to hot forging, as it preserves the fine-grain structure of bronze. Cold forging is ideal for producing intricate bronze components with tight tolerances, reduced oxidation, and enhanced wear resistance, making it a preferred method in precision applications.

Key Differences: Hot vs Cold Forging (Bronze)

Hot forging of bronze involves heating the material above its recrystallization temperature, enhancing its ductility and allowing for more complex shapes with reduced risk of cracking. Cold forging occurs at or near room temperature, resulting in higher strength and improved surface finish but requiring greater force and increasing the likelihood of strain hardening. Key differences include thermal conditions, mechanical properties, and tooling requirements, with hot forging favoring formability and cold forging producing superior dimensional accuracy and surface quality.

Mechanical Properties Comparison in Bronze Forging

Hot forging of bronze enhances ductility and reduces internal stresses, resulting in improved toughness and better grain structure refinement. Cold forging increases strength and hardness through strain hardening but may introduce residual stresses and reduce overall ductility. Mechanical properties after forging depend on temperature control, alloy composition, and deformation methods, with hot forging favoring impact resistance and cold forging optimizing dimensional accuracy.

Surface Finish and Precision: Hot vs Cold Forging

Cold forging bronze produces superior surface finish and higher dimensional precision due to minimal oxidation and material deformation at lower temperatures. Hot forging bronze involves heating above recrystallization temperature, which can lead to scale formation and reduced surface smoothness but allows for easier shaping of complex geometries. Precision in cold forged bronze parts typically exceeds hot forged counterparts, making cold forging preferable for applications requiring tight tolerances and smooth finishes.

Energy Efficiency and Cost Factors in Bronze Forging

Hot forging of bronze requires higher energy consumption due to heating processes, yet it offers improved material ductility and reduced tooling stress, potentially lowering long-term expenses. Cold forging consumes less energy by eliminating the heating phase but may increase tooling wear and result in higher rejection rates, impacting overall manufacturing costs. Evaluating energy efficiency against tooling life and defect rates is critical for optimizing cost factors in bronze forging operations.

Applications of Hot Forged Bronze Parts

Hot forged bronze parts exhibit superior mechanical properties, making them ideal for heavy-duty applications such as marine hardware, automotive components, and industrial machinery. The hot forging process enhances material strength and ductility, allowing the production of complex shapes with improved wear resistance and fatigue life. These characteristics ensure reliable performance in environments demanding high durability and corrosion resistance.

Cold Forged Bronze: Best Use Cases

Cold forged bronze offers superior dimensional accuracy and enhanced surface finish, making it ideal for precision components such as bushings, bearings, and electrical connectors. Its increased strength and work hardening properties improve wear resistance in applications requiring high durability under moderate stress. Cold forging is best suited for manufacturing small to medium-sized parts where tight tolerances and material integrity are critical.

Choosing the Right Forging Process for Bronze

Hot forging of bronze enhances ductility and reduces internal stresses, making it ideal for complex shapes and larger parts requiring superior mechanical properties. Cold forging preserves dimensional accuracy and surface finish, suitable for smaller, precision components with high strength needs. Selecting between hot and cold forging depends on desired part complexity, mechanical performance, and tolerance requirements in bronze manufacturing.

Hot Forging vs Cold Forging (Bronze) Infographic

materialdif.com

materialdif.com