Naval bronze and commercial bronze differ primarily in composition and corrosion resistance, with naval bronze containing a higher copper and tin content optimized for marine environments. This alloy exhibits superior resistance to saltwater corrosion, making it ideal for ship fittings, propellers, and underwater components. Commercial bronze, often alloyed with elements like aluminum or zinc, suits general-purpose applications where cost-effectiveness outweighs exposure to harsh conditions.

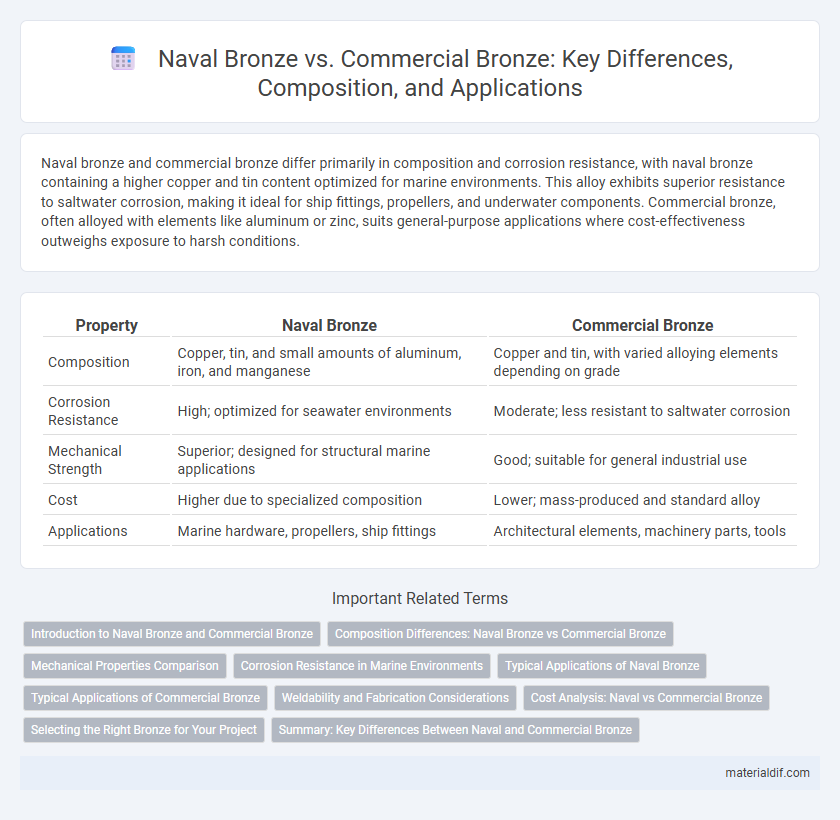

Table of Comparison

| Property | Naval Bronze | Commercial Bronze |

|---|---|---|

| Composition | Copper, tin, and small amounts of aluminum, iron, and manganese | Copper and tin, with varied alloying elements depending on grade |

| Corrosion Resistance | High; optimized for seawater environments | Moderate; less resistant to saltwater corrosion |

| Mechanical Strength | Superior; designed for structural marine applications | Good; suitable for general industrial use |

| Cost | Higher due to specialized composition | Lower; mass-produced and standard alloy |

| Applications | Marine hardware, propellers, ship fittings | Architectural elements, machinery parts, tools |

Introduction to Naval Bronze and Commercial Bronze

Naval bronze is an alloy primarily composed of copper, tin, and zinc, specifically engineered for marine applications due to its exceptional corrosion resistance in saltwater environments. Commercial bronze generally contains a higher proportion of copper and tin, designed for general-purpose use in machinery, bearings, and decorative items but lacks the enhanced anti-corrosive properties of naval bronze. The key distinction lies in naval bronze's superior durability and resistance to biofouling, making it ideal for ship fittings, propellers, and underwater fastenings.

Composition Differences: Naval Bronze vs Commercial Bronze

Naval bronze contains a higher percentage of tin, typically ranging from 8% to 10%, enhancing corrosion resistance in seawater environments compared to commercial bronze, which usually has around 5% tin. Naval bronze often includes elements like phosphorus and lead to improve strength and machinability, whereas commercial bronze prioritizes ease of casting with lower alloying content. The increased tin and alloying elements in naval bronze make it ideal for marine applications, while commercial bronze suits general industrial use.

Mechanical Properties Comparison

Naval bronze offers superior mechanical properties compared to commercial bronze, including higher tensile strength and enhanced corrosion resistance, which makes it ideal for marine environments. Its composition often includes increased amounts of tin and phosphorus, contributing to improved hardness and durability under stress. Commercial bronze generally has lower strength and wear resistance, limiting its use to less demanding applications.

Corrosion Resistance in Marine Environments

Naval Bronze offers superior corrosion resistance in marine environments due to its higher copper and tin content, which effectively combats saltwater-induced oxidation and pitting. Commercial Bronze, typically containing less tin and more zinc, is more susceptible to dezincification and surface degradation when exposed to seawater. The enhanced alloy composition of Naval Bronze ensures prolonged durability and structural integrity in harsh marine conditions, making it the preferred choice for maritime applications.

Typical Applications of Naval Bronze

Naval bronze is primarily used in marine environments for components such as ship propellers, underwater fasteners, and pump shafts due to its superior corrosion resistance in seawater compared to commercial bronze. Its high strength and durability make it ideal for critical applications in shipbuilding and offshore structures where exposure to saltwater and mechanical stress is constant. Unlike commercial bronze, which often serves decorative or low-strength purposes, naval bronze is engineered to withstand harsh maritime conditions and kinetic wear.

Typical Applications of Commercial Bronze

Commercial bronze is widely used in architectural hardware, plumbing fittings, and electrical connectors due to its excellent corrosion resistance and ease of machining. Typical applications include valves, pump components, and marine hardware where moderate strength and good wear resistance are essential. Its antimicrobial properties also make it suitable for door handles and hospital equipment, ensuring hygiene and durability.

Weldability and Fabrication Considerations

Naval bronze offers superior weldability compared to commercial bronze due to its carefully controlled alloy composition, which minimizes porosity and cracking during welding. Fabrication of naval bronze requires attention to its higher copper content and added elements like tin and zinc, enhancing corrosion resistance and making it suitable for marine environments. Commercial bronze, while easier to cast and machine, often lacks the enhanced weldability and durability features necessary for demanding fabrications in seawater applications.

Cost Analysis: Naval vs Commercial Bronze

Naval bronze typically incurs higher costs due to its superior corrosion resistance and added alloying elements like nickel and tin, making it ideal for marine environments. Commercial bronze offers a more economical option with reduced alloy complexity, suitable for less demanding applications where cost efficiency is prioritized over enhanced durability. The initial investment in naval bronze is offset by its longer lifespan and lower maintenance, resulting in potentially lower total cost of ownership compared to commercial bronze.

Selecting the Right Bronze for Your Project

Naval bronze offers superior corrosion resistance and strength due to its higher copper and tin content, making it ideal for marine environments and heavy-duty applications. Commercial bronze, with its varied alloy compositions, suits general-purpose uses where cost-effectiveness and moderate durability are priorities. Selecting the right bronze depends on evaluating environmental exposure, mechanical stress, and specific project requirements to ensure longevity and performance.

Summary: Key Differences Between Naval and Commercial Bronze

Naval Bronze features higher corrosion resistance due to its increased nickel and iron content, making it ideal for marine environments. Commercial Bronze typically contains less nickel and is more prone to dezincification, reducing its durability in seawater applications. The enhanced alloy composition in Naval Bronze ensures superior strength and longevity for shipbuilding and underwater hardware compared to standard Commercial Bronze.

Naval Bronze vs Commercial Bronze Infographic

materialdif.com

materialdif.com