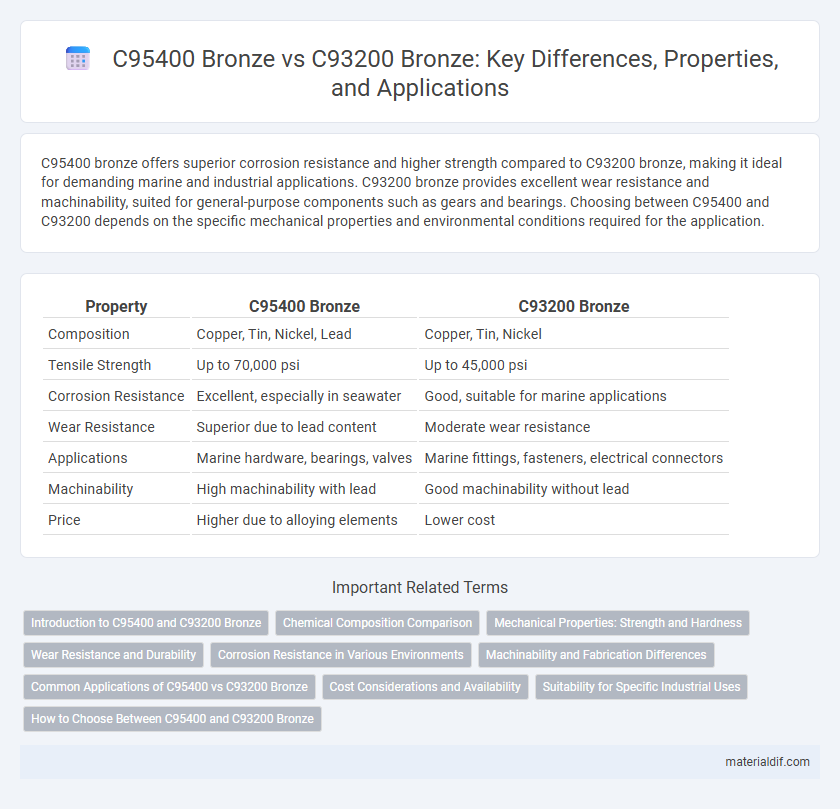

C95400 bronze offers superior corrosion resistance and higher strength compared to C93200 bronze, making it ideal for demanding marine and industrial applications. C93200 bronze provides excellent wear resistance and machinability, suited for general-purpose components such as gears and bearings. Choosing between C95400 and C93200 depends on the specific mechanical properties and environmental conditions required for the application.

Table of Comparison

| Property | C95400 Bronze | C93200 Bronze |

|---|---|---|

| Composition | Copper, Tin, Nickel, Lead | Copper, Tin, Nickel |

| Tensile Strength | Up to 70,000 psi | Up to 45,000 psi |

| Corrosion Resistance | Excellent, especially in seawater | Good, suitable for marine applications |

| Wear Resistance | Superior due to lead content | Moderate wear resistance |

| Applications | Marine hardware, bearings, valves | Marine fittings, fasteners, electrical connectors |

| Machinability | High machinability with lead | Good machinability without lead |

| Price | Higher due to alloying elements | Lower cost |

Introduction to C95400 and C93200 Bronze

C95400 bronze, also known as high-strength leaded aluminum bronze, contains approximately 7-10% aluminum, 5% iron, and 5% nickel, providing excellent wear resistance and corrosion resistance in marine environments. C93200 bronze, or aluminum bronze with similar nickel and iron content but lower aluminum percentage, offers good strength and moderate corrosion resistance primarily used in general industrial applications. Both alloys exhibit superior mechanical properties and fatigue resistance, with C95400 preferred for demanding applications requiring higher strength and toughness.

Chemical Composition Comparison

C95400 bronze primarily consists of approximately 9-10% tin, 1.8-2.4% lead, with the remainder mostly copper, enhancing its machinability and corrosion resistance. C93200 bronze contains about 7-9% tin, 1.9-2.5% lead, and a copper base, offering slightly different mechanical properties and wear resistance. The higher tin content in C95400 increases hardness and tensile strength compared to C93200, which impacts their application suitability in bearing and wear components.

Mechanical Properties: Strength and Hardness

C95400 bronze exhibits higher tensile strength, typically ranging from 560 to 690 MPa, compared to C93200 bronze's range of 380 to 520 MPa, making it more suitable for applications requiring greater mechanical durability. In terms of hardness, C95400 generally achieves Rockwell B values around 95-105, whereas C93200 measures lower, around 80-95 HRB, indicating C95400's superior resistance to surface deformation. The enhanced strength and hardness of C95400 bronze are attributed to its higher nickel and tin content, providing improved wear resistance over C93200 bronze.

Wear Resistance and Durability

C95400 Bronze offers superior wear resistance compared to C93200 Bronze due to its higher tin content and optimized alloy composition, enhancing its durability in heavy-load applications. The enhanced wear resistance of C95400 makes it ideal for components subjected to friction and abrasion, such as bearings and bushings, ensuring longer service life. In contrast, C93200 Bronze, while durable, exhibits slightly lower wear resistance, making it more suitable for moderate wear environments.

Corrosion Resistance in Various Environments

C95400 bronze exhibits superior corrosion resistance compared to C93200 bronze, especially in marine and industrial environments due to its higher tin content and balanced alloy composition. This grade maintains structural integrity and resists dezincification and stress corrosion cracking better, making it ideal for seawater applications and harsh chemical exposures. Conversely, C93200 bronze shows moderate corrosion resistance, performing adequately in less aggressive environments but prone to more rapid degradation under severe conditions.

Machinability and Fabrication Differences

C95400 bronze offers superior machinability compared to C93200, making it more suitable for precision machining applications. The higher lead content in C95400 reduces tool wear and improves surface finish, whereas C93200 bronze exhibits greater strength but is harder to machine. Fabrication techniques for C95400 typically involve easier cutting and drilling processes, while C93200 requires more robust tooling due to its increased hardness and tensile strength.

Common Applications of C95400 vs C93200 Bronze

C95400 bronze, known for its excellent corrosion resistance and high strength, is commonly used in marine hardware, valve components, and pump parts where exposure to seawater and mechanical stress is frequent. C93200 bronze, favored for its good corrosion resistance and machinability, is typically applied in electrical connectors, architectural hardware, and plumbing fittings. Both alloys serve critical roles in environments requiring durability and resistance to wear, with C95400 preferred for harsher conditions and C93200 selected for moderate stress applications.

Cost Considerations and Availability

C95400 bronze generally commands a higher price due to its superior strength and corrosion resistance, making it ideal for demanding industrial applications. C93200 bronze is more cost-effective and widely available, benefiting projects with tighter budgets and less stringent performance requirements. Availability of C93200 is more consistent globally, while C95400 may experience supply variability depending on regional demand and specialty foundries.

Suitability for Specific Industrial Uses

C95400 Bronze, known for its high strength and excellent corrosion resistance, is highly suitable for aerospace and marine applications where durability and wear resistance are critical. C93200 Bronze offers superior machinability and good wear properties, making it ideal for intricate components in electrical and hydraulic systems. Selecting between C95400 and C93200 depends on the required balance of mechanical strength and ease of manufacturing in specific industrial environments.

How to Choose Between C95400 and C93200 Bronze

Selecting between C95400 and C93200 bronze depends on specific application needs such as corrosion resistance and mechanical strength. C95400 bronze offers superior wear resistance and is ideal for bearing applications, while C93200 bronze provides enhanced machinability and is suited for intricate components. Evaluating operational environment, load conditions, and manufacturing requirements will guide the optimal choice between these two copper alloys.

C95400 Bronze vs C93200 Bronze Infographic

materialdif.com

materialdif.com