Rolled bronze sheets offer superior dimensional accuracy and a smoother surface finish compared to cast bronze plates, making them ideal for applications requiring tight tolerances and aesthetic appeal. Cast bronze plates, produced by pouring molten bronze into molds, provide excellent strength and durability, suitable for heavy-duty structural uses and intricate shapes. Choosing between rolled sheets and cast plates depends on the specific performance requirements, with rolled sheets favored for precision metalworking and cast plates preferred for robust, large-scale projects.

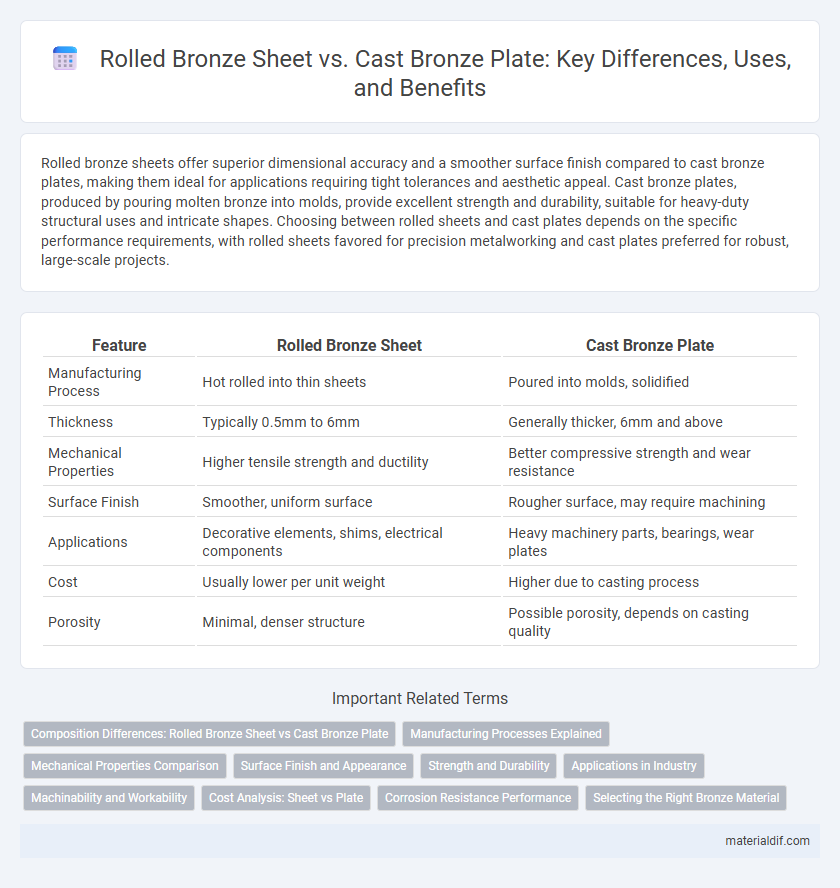

Table of Comparison

| Feature | Rolled Bronze Sheet | Cast Bronze Plate |

|---|---|---|

| Manufacturing Process | Hot rolled into thin sheets | Poured into molds, solidified |

| Thickness | Typically 0.5mm to 6mm | Generally thicker, 6mm and above |

| Mechanical Properties | Higher tensile strength and ductility | Better compressive strength and wear resistance |

| Surface Finish | Smoother, uniform surface | Rougher surface, may require machining |

| Applications | Decorative elements, shims, electrical components | Heavy machinery parts, bearings, wear plates |

| Cost | Usually lower per unit weight | Higher due to casting process |

| Porosity | Minimal, denser structure | Possible porosity, depends on casting quality |

Composition Differences: Rolled Bronze Sheet vs Cast Bronze Plate

Rolled bronze sheet typically contains higher copper content with controlled additions of tin and small percentages of phosphorus to enhance malleability and surface finish. Cast bronze plate usually has a more varied composition including copper, tin, and sometimes zinc or lead, optimized for durability and wear resistance in bulky shapes. The compositional differences directly affect mechanical properties, with rolled sheets favoring flexibility and smooth surfaces, whereas cast plates emphasize strength and hardness.

Manufacturing Processes Explained

Rolled bronze sheets are produced by passing heated bronze slabs through heavy rollers to achieve uniform thickness and a smooth surface, ensuring enhanced mechanical properties and structural integrity. Cast bronze plates are created by pouring molten bronze into molds, allowing the metal to cool and solidify naturally, which results in varying grain structures and potential porosity. The rolled process offers better surface finish and dimensional accuracy, while casting allows for larger, thicker plates with complex shapes.

Mechanical Properties Comparison

Rolled bronze sheets exhibit higher tensile strength and improved ductility due to their uniform grain structure formed during the rolling process, making them ideal for applications requiring flexibility and impact resistance. Cast bronze plates, while generally possessing higher hardness and wear resistance from their solidification process, tend to have lower tensile strength and increased brittleness, which can limit their use in dynamic mechanical environments. The choice between rolled and cast bronze depends on the mechanical property requirements such as strength, toughness, and wear resistance for specific industrial applications.

Surface Finish and Appearance

Rolled bronze sheets exhibit a smooth, uniform surface finish due to the continuous rolling process, enhancing their aesthetic appeal and making them ideal for decorative applications. Cast bronze plates typically have a rougher, textured surface with visible grain structures and occasional surface imperfections, resulting from the solidification process in molds. The choice between rolled and cast bronze largely depends on the required surface finish and visual quality for the intended use.

Strength and Durability

Rolled bronze sheets exhibit superior strength and durability compared to cast bronze plates due to their refined grain structure formed through mechanical rolling processes, which enhances tensile strength and resistance to wear. Cast bronze plates, while offering good corrosion resistance and toughness, often contain micro-porosities that can reduce structural integrity under heavy stress. For applications requiring high mechanical performance and impact resistance, rolled bronze sheets provide more reliable long-term durability.

Applications in Industry

Rolled bronze sheets are widely used in industries requiring precise thickness and smooth surface finishes, such as electrical connectors, automotive components, and decorative architectural elements. Cast bronze plates, known for their durability and strength, are preferred in heavy machinery bases, marine hardware, and wear-resistant industrial parts. Both forms offer excellent corrosion resistance and thermal conductivity, making them suitable for applications in harsh environments and high-temperature conditions.

Machinability and Workability

Rolled bronze sheet offers superior machinability due to its uniform grain structure and consistent thickness, allowing for precise cutting and shaping with minimal tool wear. Cast bronze plate, although excellent for complex shapes and heavier sections, tends to have a coarser grain, which can reduce machinability and increase the likelihood of tool degradation. In terms of workability, rolled bronze exhibits better ductility and surface finish, making it ideal for applications requiring tight tolerances and smooth finishes.

Cost Analysis: Sheet vs Plate

Rolled bronze sheet typically incurs lower production costs due to its continuous manufacturing process, making it more cost-effective for large-scale applications compared to cast bronze plate, which involves a more labor-intensive pouring and cooling method. Cast bronze plates, while generally more expensive, offer superior dimensional thickness and heavier section capabilities, justifying their cost in structural or heavy-duty projects. Cost analysis must also consider post-production machining; rolled sheets require less machining, reducing overall expenses, whereas cast plates often need more extensive finishing work, increasing total project costs.

Corrosion Resistance Performance

Rolled bronze sheets exhibit superior corrosion resistance due to their dense and uniform microstructure formed during the rolling process, which minimizes porosity and prevents moisture ingress. Cast bronze plates, while strong, often contain microscopic voids and inclusions that can lead to localized corrosion over time. In marine and industrial environments, rolled bronze sheets maintain structural integrity and resist oxidation more effectively than cast bronze plates, enhancing longevity.

Selecting the Right Bronze Material

Rolled bronze sheet offers superior strength and uniform grain structure ideal for applications requiring high mechanical performance and precise dimensions, while cast bronze plate provides excellent corrosion resistance and intricate shapes suitable for heavy-duty or artistic uses. Selecting the right bronze material depends on factors like the required tensile strength, desired surface finish, and environmental exposure. Considering the specific mechanical properties and production methods ensures optimal durability and functionality for industrial or decorative projects.

Rolled Bronze Sheet vs Cast Bronze Plate Infographic

materialdif.com

materialdif.com