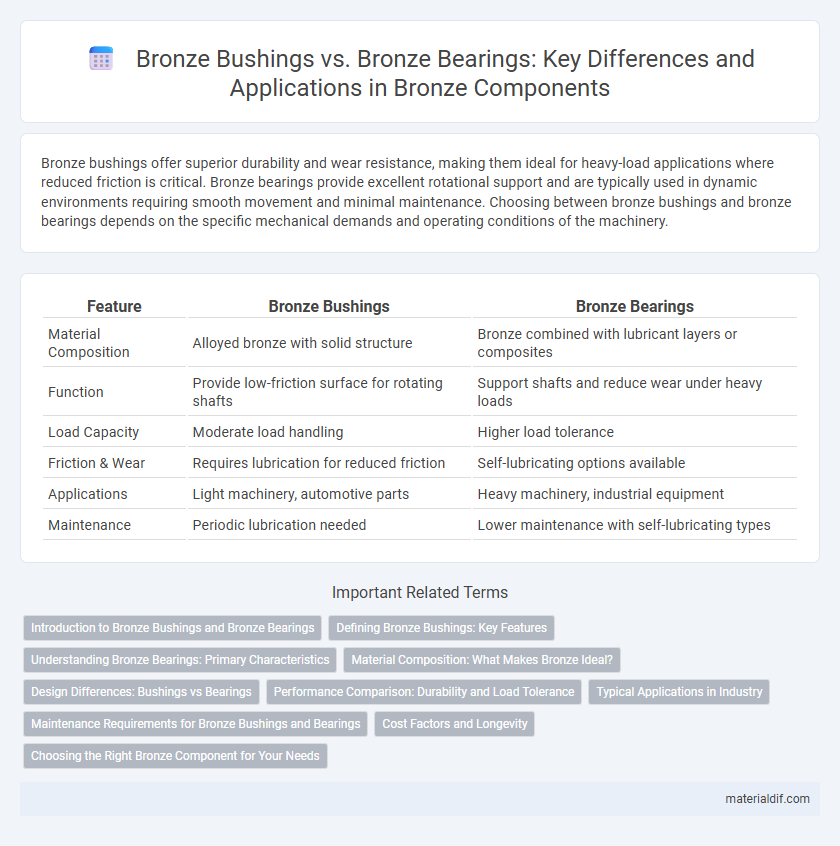

Bronze bushings offer superior durability and wear resistance, making them ideal for heavy-load applications where reduced friction is critical. Bronze bearings provide excellent rotational support and are typically used in dynamic environments requiring smooth movement and minimal maintenance. Choosing between bronze bushings and bronze bearings depends on the specific mechanical demands and operating conditions of the machinery.

Table of Comparison

| Feature | Bronze Bushings | Bronze Bearings |

|---|---|---|

| Material Composition | Alloyed bronze with solid structure | Bronze combined with lubricant layers or composites |

| Function | Provide low-friction surface for rotating shafts | Support shafts and reduce wear under heavy loads |

| Load Capacity | Moderate load handling | Higher load tolerance |

| Friction & Wear | Requires lubrication for reduced friction | Self-lubricating options available |

| Applications | Light machinery, automotive parts | Heavy machinery, industrial equipment |

| Maintenance | Periodic lubrication needed | Lower maintenance with self-lubricating types |

Introduction to Bronze Bushings and Bronze Bearings

Bronze bushings and bronze bearings are essential components in machinery designed to reduce friction and wear between moving parts. Bronze bushings typically serve as sleeves or liners, providing a durable, low-friction surface for rotating shafts, while bronze bearings may include ball or roller types that support radial and axial loads more dynamically. Both utilize the inherent strength, corrosion resistance, and thermal conductivity of bronze alloys to enhance mechanical performance and longevity.

Defining Bronze Bushings: Key Features

Bronze bushings are cylindrical components made from bronze alloys, designed to reduce friction between moving parts and provide wear resistance in mechanical systems. They typically feature high thermal conductivity and excellent corrosion resistance, making them suitable for heavy-load, low-speed applications with minimal maintenance requirements. Unlike bronze bearings, bushings are primarily used as plain bearings without rolling elements, emphasizing simplicity and durability in shaft support and alignment.

Understanding Bronze Bearings: Primary Characteristics

Bronze bearings are engineered to provide superior wear resistance, high load capacity, and excellent corrosion resistance, making them ideal for heavy-duty and high-speed applications. These bearings typically contain alloys with elements such as tin, phosphorus, and aluminum, which enhance their strength and durability under frictional forces. Unlike bushings, bronze bearings often incorporate precision-machined surfaces and lubrication reservoirs to ensure smooth operation and extended service life in various industrial environments.

Material Composition: What Makes Bronze Ideal?

Bronze bushings and bronze bearings both leverage the alloy's high copper content combined with tin, aluminum, or phosphorus to provide exceptional strength and corrosion resistance. The material composition of bronze grants excellent wear resistance and low friction coefficients, making it ideal for applications requiring durability under high loads. Its thermal conductivity and self-lubricating properties reduce maintenance needs while enhancing performance in demanding mechanical environments.

Design Differences: Bushings vs Bearings

Bronze bushings are typically solid, cylindrical components designed to provide low-friction support for rotating shafts, relying on their material properties to minimize wear. In contrast, bronze bearings often incorporate design features such as embedded lubricants or split constructions that enhance load capacity and reduce maintenance needs. The fundamental design difference lies in bushings serving as simple sleeves, while bearings are engineered to accommodate dynamic loads through advanced structural adaptations.

Performance Comparison: Durability and Load Tolerance

Bronze bushings exhibit superior durability under heavy loads due to their solid structure that resists deformation and wear over extended use, making them ideal for high-pressure environments. Bronze bearings, while offering excellent load tolerance and smooth rotational performance, typically incorporate softer materials or lubricants that may reduce lifespan under extreme stress. The choice between bronze bushings and bearings depends heavily on specific performance requirements, where bushings excel in longevity and load-bearing capacity, and bearings provide enhanced motion efficiency.

Typical Applications in Industry

Bronze bushings are commonly used in heavy machinery and automotive applications due to their excellent wear resistance and ability to handle high loads with minimal lubrication. Bronze bearings are preferred in precision instruments and electrical equipment where low friction and smooth rotational movement are critical. Both components serve vital roles in industries such as construction, agriculture, and manufacturing, optimizing performance and durability under varying operating conditions.

Maintenance Requirements for Bronze Bushings and Bearings

Bronze bushings require minimal lubrication and periodic inspection to prevent wear and corrosion, making maintenance straightforward compared to bronze bearings, which often need consistent lubrication and regular cleaning to maintain optimal performance. Bronze bearings typically demand more frequent monitoring to ensure the lubricant remains effective and to avoid contamination that can lead to premature failure. Proper maintenance of both components extends their operational lifespan but bronze bushings generally offer lower maintenance demands in industrial applications.

Cost Factors and Longevity

Bronze bushings generally offer a lower initial cost compared to bronze bearings due to simpler manufacturing processes and less precision machining. Bronze bearings, while more expensive upfront, provide superior longevity and wear resistance, reducing long-term replacement and maintenance expenses. Evaluating cost factors alongside expected service life is crucial for applications requiring durability and budget efficiency.

Choosing the Right Bronze Component for Your Needs

Bronze bushings provide excellent wear resistance and low friction, making them ideal for applications with high load and low speed. Bronze bearings, typically composed of bronze alloys embedded with solid lubricants, excel in dynamic environments requiring continuous lubrication and shock absorption. Selecting the right bronze component depends on factors such as load, speed, lubrication conditions, and environmental exposure to ensure optimal performance and longevity.

Bronze Bushings vs Bronze Bearings Infographic

materialdif.com

materialdif.com