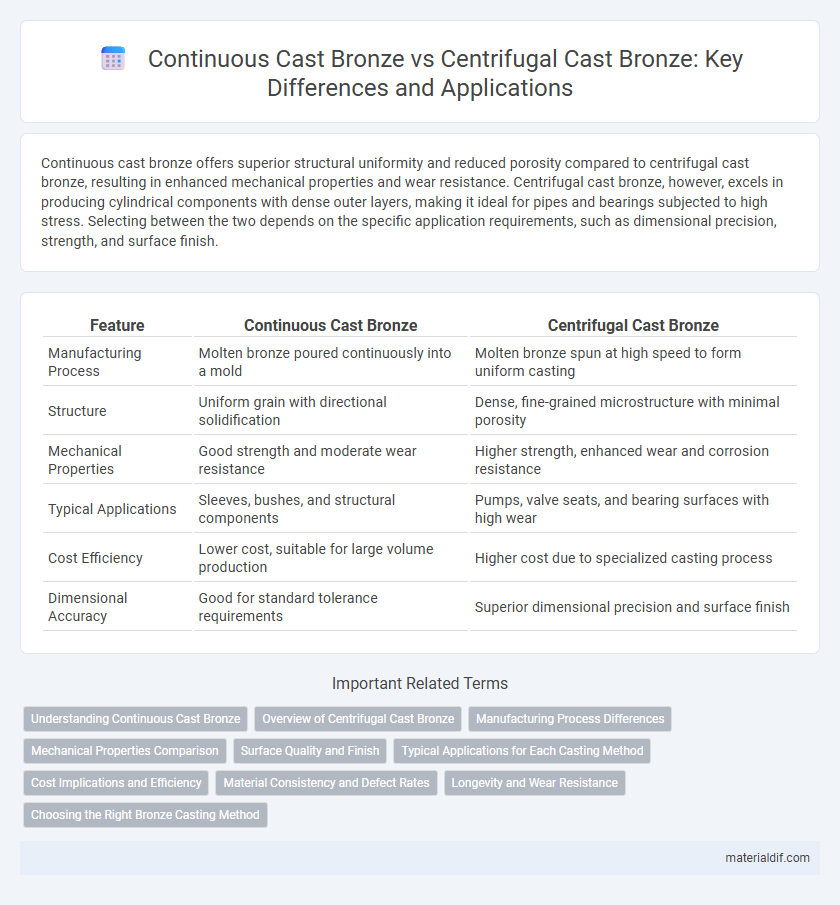

Continuous cast bronze offers superior structural uniformity and reduced porosity compared to centrifugal cast bronze, resulting in enhanced mechanical properties and wear resistance. Centrifugal cast bronze, however, excels in producing cylindrical components with dense outer layers, making it ideal for pipes and bearings subjected to high stress. Selecting between the two depends on the specific application requirements, such as dimensional precision, strength, and surface finish.

Table of Comparison

| Feature | Continuous Cast Bronze | Centrifugal Cast Bronze |

|---|---|---|

| Manufacturing Process | Molten bronze poured continuously into a mold | Molten bronze spun at high speed to form uniform casting |

| Structure | Uniform grain with directional solidification | Dense, fine-grained microstructure with minimal porosity |

| Mechanical Properties | Good strength and moderate wear resistance | Higher strength, enhanced wear and corrosion resistance |

| Typical Applications | Sleeves, bushes, and structural components | Pumps, valve seats, and bearing surfaces with high wear |

| Cost Efficiency | Lower cost, suitable for large volume production | Higher cost due to specialized casting process |

| Dimensional Accuracy | Good for standard tolerance requirements | Superior dimensional precision and surface finish |

Understanding Continuous Cast Bronze

Continuous Cast Bronze features a uniform microstructure due to its consistent solidification process, resulting in enhanced mechanical properties and superior corrosion resistance. This casting method produces bronze with fewer internal defects and improved dimensional accuracy compared to Centrifugal Cast Bronze. Its controlled manufacturing environment makes Continuous Cast Bronze ideal for precision components in marine, industrial, and bearing applications.

Overview of Centrifugal Cast Bronze

Centrifugal cast bronze is a manufacturing process where molten bronze is poured into a rotating mold, utilizing centrifugal force to achieve a dense, homogeneous metal structure with minimal impurities. This method enhances mechanical properties such as strength, wear resistance, and corrosion resistance, making it ideal for high-performance industrial components like bearings and bushings. Compared to continuous cast bronze, centrifugal casting produces components with superior dimensional accuracy and material integrity, suitable for demanding applications in marine and automotive industries.

Manufacturing Process Differences

Continuous cast bronze is produced by pouring molten metal into a mold with a steady flow, resulting in uniform grain structure and consistent mechanical properties ideal for mass production. Centrifugal cast bronze involves spinning a mold at high speeds while pouring the metal, which forces denser material toward the outer walls, enhancing density and reducing porosity in cylindrical components. The continuous casting method emphasizes efficiency and dimensional precision, whereas centrifugal casting offers superior structural integrity for parts subjected to high stress.

Mechanical Properties Comparison

Continuous cast bronze exhibits superior tensile strength and uniformity compared to centrifugal cast bronze, due to its refined microstructure achieved through controlled solidification. Centrifugal cast bronze typically has higher density and improved resistance to centrifugal forces, making it ideal for components subjected to rotational stress. Mechanical property variations between these methods influence application suitability, with continuous cast bronze favored for structural applications and centrifugal cast bronze preferred for wear-resistant parts.

Surface Quality and Finish

Continuous cast bronze exhibits superior surface quality and a smoother finish due to its controlled solidification process, which minimizes porosity and surface imperfections. In contrast, centrifugal cast bronze often presents a rougher exterior with potential machining marks resulting from its rotational mold casting technique. The continuous cast method is preferred for applications requiring high precision and aesthetic surface integrity.

Typical Applications for Each Casting Method

Continuous cast bronze is commonly used for manufacturing components requiring uniform structure and precise dimensions, such as bearings, bushings, and valve parts in automotive and industrial machinery. Centrifugal cast bronze is ideal for producing large, cylindrical, and wear-resistant parts like pump sleeves, cylinder liners, and heavy-duty sleeves in marine, petroleum, and power generation industries. The choice between continuous and centrifugal casting depends on application-specific demands for mechanical properties, dimensional accuracy, and size constraints.

Cost Implications and Efficiency

Continuous cast bronze offers lower production costs due to its streamlined manufacturing process and reduced material waste, making it cost-effective for high-volume applications. Centrifugal cast bronze, while more expensive upfront, provides superior density and mechanical properties, enhancing efficiency in high-stress environments. Selecting between the two depends on balancing initial investment against long-term performance requirements and operational efficiency.

Material Consistency and Defect Rates

Continuous cast bronze offers superior material consistency due to its uniform solidification process, resulting in fewer internal defects and enhanced mechanical properties. Centrifugal cast bronze, while effective in producing dense outer layers, tends to have variable microstructures and higher defect rates such as porosity and inclusions in the core. Selecting continuous casting improves reliability and performance in applications requiring precise material integrity.

Longevity and Wear Resistance

Continuous cast bronze demonstrates superior wear resistance due to its uniform microstructure, resulting in extended longevity under high-friction conditions. Centrifugal cast bronze offers enhanced density and reduced porosity, which improves its durability but may have slightly less uniform wear properties compared to continuous cast variants. Selecting continuous cast bronze is ideal for applications demanding consistent performance and prolonged service life.

Choosing the Right Bronze Casting Method

Continuous cast bronze offers superior dimensional accuracy and consistent metal structure, making it ideal for complex components requiring tight tolerances. Centrifugal cast bronze excels in producing dense, defect-free cylindrical parts with high mechanical strength due to its radial solidification process. Selecting the right bronze casting method depends on part geometry, mechanical property requirements, and production volume to optimize performance and cost-efficiency.

Continuous Cast Bronze vs Centrifugal Cast Bronze Infographic

materialdif.com

materialdif.com