Rolled bronze offers a more uniform grain structure and superior strength compared to cast bronze, making it ideal for applications requiring high durability and toughness. Cast bronze, produced by pouring molten metal into molds, allows for complex shapes and intricate designs but may have less consistent mechanical properties. Choosing between rolled and cast bronze depends on the specific requirements for strength, detail, and production method efficiency.

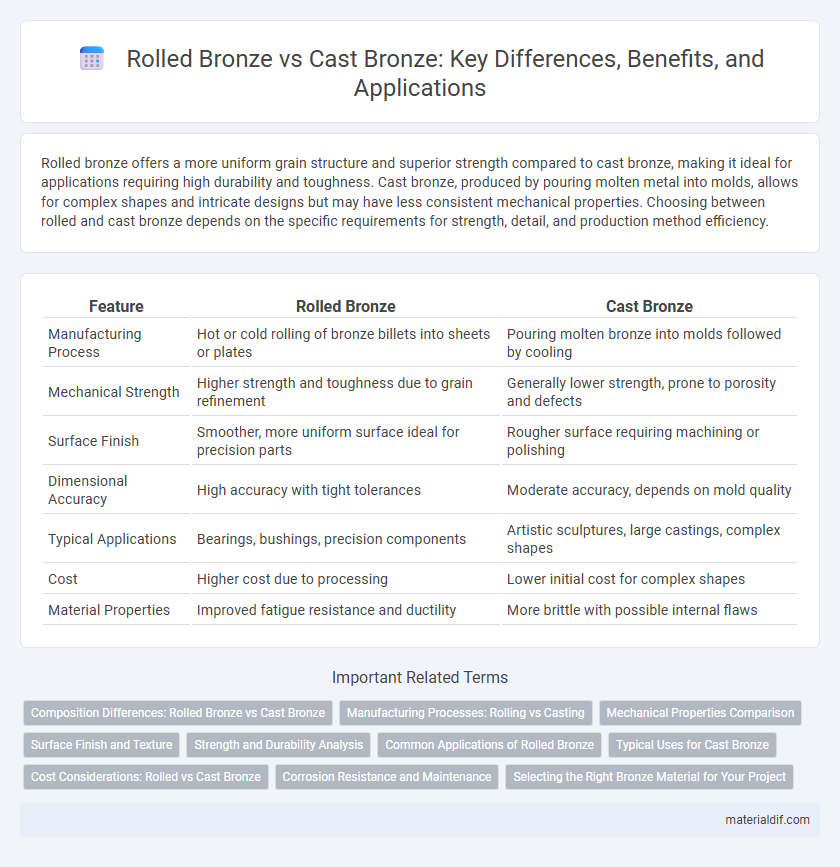

Table of Comparison

| Feature | Rolled Bronze | Cast Bronze |

|---|---|---|

| Manufacturing Process | Hot or cold rolling of bronze billets into sheets or plates | Pouring molten bronze into molds followed by cooling |

| Mechanical Strength | Higher strength and toughness due to grain refinement | Generally lower strength, prone to porosity and defects |

| Surface Finish | Smoother, more uniform surface ideal for precision parts | Rougher surface requiring machining or polishing |

| Dimensional Accuracy | High accuracy with tight tolerances | Moderate accuracy, depends on mold quality |

| Typical Applications | Bearings, bushings, precision components | Artistic sculptures, large castings, complex shapes |

| Cost | Higher cost due to processing | Lower initial cost for complex shapes |

| Material Properties | Improved fatigue resistance and ductility | More brittle with possible internal flaws |

Composition Differences: Rolled Bronze vs Cast Bronze

Rolled bronze typically consists of a copper-tin alloy with uniform grain structure achieved through mechanical deformation, enhancing its strength and malleability. Cast bronze contains the same base metals but may include additional elements like aluminum or silicon to improve fluidity and castability, resulting in a coarser microstructure with varied tensile properties. The composition differences directly influence the mechanical performance and application suitability of rolled versus cast bronze in industrial and artistic contexts.

Manufacturing Processes: Rolling vs Casting

Rolled bronze is produced by passing bronze alloy slabs through rollers at high temperature, resulting in a uniform thickness and enhanced mechanical properties due to metal grain alignment. Cast bronze involves melting the alloy and pouring it into molds, allowing for complex shapes but with potential variations in density and internal porosity. Rolling offers superior structural consistency and surface finish, while casting provides flexibility in design and size for bronze components.

Mechanical Properties Comparison

Rolled bronze exhibits higher tensile strength and improved ductility compared to cast bronze, making it more suitable for applications requiring enhanced mechanical performance. Cast bronze typically shows greater brittleness due to its solidification process, resulting in lower impact resistance and fatigue life. The grain structure in rolled bronze is more refined and uniform, contributing to superior wear resistance and toughness relative to the coarse microstructure of cast bronze.

Surface Finish and Texture

Rolled bronze exhibits a smoother and more consistent surface finish due to the mechanical process that compresses and elongates the metal, enhancing its texture uniformity. Cast bronze, formed by pouring molten metal into a mold, often features a rougher, more irregular surface with visible casting marks or porosity. The choice between rolled and cast bronze depends on the desired aesthetic and functional requirements, with rolled bronze favored for high-precision applications needing a refined finish.

Strength and Durability Analysis

Rolled bronze exhibits enhanced strength and durability due to the metal's refined grain structure achieved through the rolling process, resulting in improved tensile strength and resistance to fatigue. Cast bronze, while offering more intricate shapes, typically features a coarser grain and higher porosity, which can reduce overall structural integrity under stress conditions. The superior mechanical properties of rolled bronze make it preferable for applications requiring sustained load-bearing performance and wear resistance.

Common Applications of Rolled Bronze

Rolled bronze offers superior strength and uniformity compared to cast bronze, making it ideal for applications requiring high durability and precision. It is commonly used in architectural hardware, industrial machinery components, and electrical connectors due to its excellent wear resistance and conductivity. Rolled bronze sheets and strips also serve critical roles in marine environments, where corrosion resistance is essential.

Typical Uses for Cast Bronze

Cast bronze is typically used for creating complex shapes and intricate details in sculptures, architectural fittings, and industrial components due to its excellent moldability and strength. It is commonly found in applications requiring high durability and wear resistance, such as bearings, bushings, and marine hardware. The material's ability to withstand corrosion and mechanical stress makes it ideal for heavy-duty castings in machinery and decorative art pieces.

Cost Considerations: Rolled vs Cast Bronze

Rolled bronze typically incurs lower production costs due to its efficient manufacturing process, which involves deforming metal sheets under controlled pressure, reducing material waste. Cast bronze, on the other hand, demands higher tooling and mold expenses, along with longer production times, driving up overall costs. For large-scale or intricate designs, rolled bronze offers a cost-effective solution, while cast bronze justifies higher prices with superior detail and structural complexity.

Corrosion Resistance and Maintenance

Rolled bronze exhibits superior corrosion resistance due to its dense, uniform grain structure, which limits the penetration of oxidizing agents, while cast bronze may contain micro-porosities that increase susceptibility to corrosion. Maintenance requirements for rolled bronze are generally lower, as its smooth surface resists tarnishing and facilitates easier cleaning compared to the more textured surface of cast bronze. Selecting rolled bronze enhances durability and reduces long-term upkeep costs in environments exposed to moisture or chemicals.

Selecting the Right Bronze Material for Your Project

Rolled bronze offers superior strength and uniformity due to its manufacturing process, making it ideal for applications requiring high durability and precise thickness. Cast bronze provides excellent intricate detail and complex shapes, suitable for decorative or specialized components. Selecting the right bronze material depends on project needs for mechanical properties, finish quality, and dimensional accuracy.

Rolled Bronze vs Cast Bronze Infographic

materialdif.com

materialdif.com