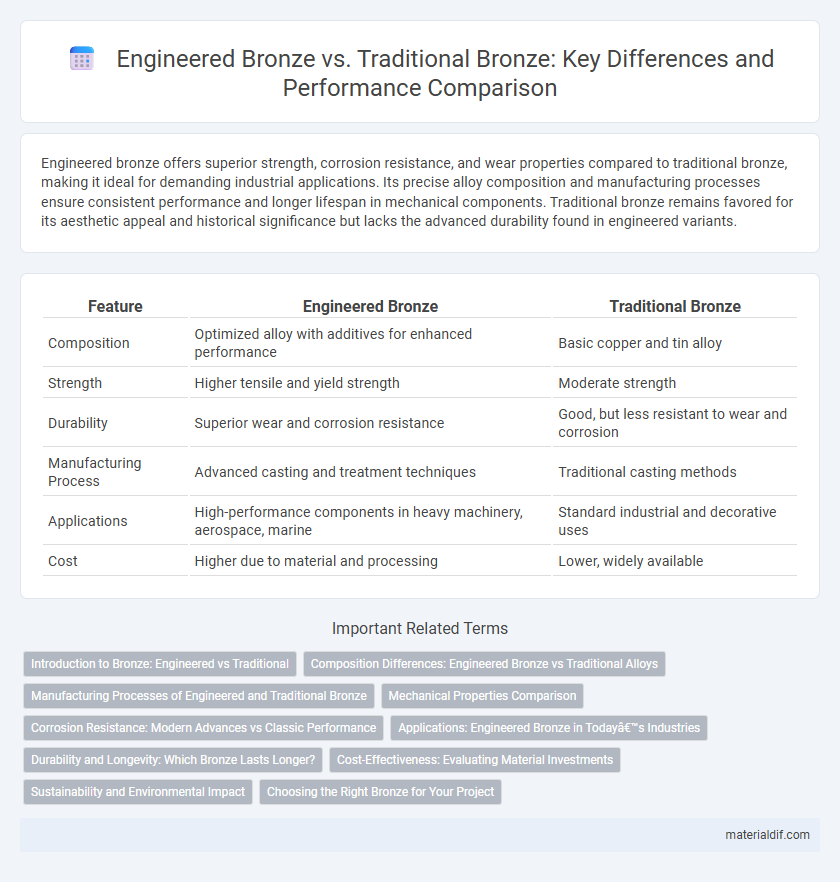

Engineered bronze offers superior strength, corrosion resistance, and wear properties compared to traditional bronze, making it ideal for demanding industrial applications. Its precise alloy composition and manufacturing processes ensure consistent performance and longer lifespan in mechanical components. Traditional bronze remains favored for its aesthetic appeal and historical significance but lacks the advanced durability found in engineered variants.

Table of Comparison

| Feature | Engineered Bronze | Traditional Bronze |

|---|---|---|

| Composition | Optimized alloy with additives for enhanced performance | Basic copper and tin alloy |

| Strength | Higher tensile and yield strength | Moderate strength |

| Durability | Superior wear and corrosion resistance | Good, but less resistant to wear and corrosion |

| Manufacturing Process | Advanced casting and treatment techniques | Traditional casting methods |

| Applications | High-performance components in heavy machinery, aerospace, marine | Standard industrial and decorative uses |

| Cost | Higher due to material and processing | Lower, widely available |

Introduction to Bronze: Engineered vs Traditional

Engineered bronze offers enhanced mechanical properties and corrosion resistance compared to traditional bronze alloys, achieved through precise control of composition and advanced manufacturing techniques. Traditional bronze, primarily an alloy of copper and tin, has been valued for its durability and workability in historical applications. Modern engineered bronze variants incorporate elements such as aluminum, nickel, or phosphorus to optimize performance for specific industrial uses.

Composition Differences: Engineered Bronze vs Traditional Alloys

Engineered bronze alloys feature precise compositional adjustments, incorporating elements such as aluminum, nickel, or silicon to enhance mechanical properties and corrosion resistance, unlike traditional bronzes primarily composed of copper and tin. These modifications result in superior strength, wear resistance, and durability tailored for specific industrial applications. Traditional bronze alloys, with their simpler copper-tin base, offer excellent casting and corrosion resistance but lack the optimized performance characteristics found in engineered variants.

Manufacturing Processes of Engineered and Traditional Bronze

Engineered bronze is produced through advanced manufacturing processes such as powder metallurgy and precision casting, allowing for enhanced control over alloy composition and microstructure, leading to improved mechanical properties and corrosion resistance. Traditional bronze manufacturing relies on sand casting or investment casting methods, where molten copper and tin are combined and poured into molds, resulting in less uniformity and potential casting defects. The precision of engineered bronze processes enables tailored properties for specific applications, while traditional methods emphasize cost-effectiveness and historical craftsmanship.

Mechanical Properties Comparison

Engineered bronze alloys exhibit superior mechanical properties compared to traditional bronze, including higher tensile strength, improved wear resistance, and enhanced corrosion resistance, making them ideal for high-performance applications. Advanced alloying elements such as nickel, aluminum, and silicon contribute to increased hardness and fatigue strength in engineered bronze. These enhancements enable components made from engineered bronze to withstand greater stress and extend service life under demanding mechanical conditions.

Corrosion Resistance: Modern Advances vs Classic Performance

Engineered bronze alloys incorporate advanced elements such as aluminum, nickel, and phosphorus, significantly enhancing corrosion resistance compared to traditional bronze, which primarily consists of copper and tin. These modern alloys exhibit superior performance in harsh environments, including marine and chemical applications, by forming more stable and protective oxide layers. Traditional bronze offers reliable corrosion resistance in general conditions, but engineered bronze provides tailored properties to meet specific industrial demands with extended durability.

Applications: Engineered Bronze in Today’s Industries

Engineered bronze alloys offer superior wear resistance and enhanced machinability compared to traditional bronze, making them ideal for high-performance applications in aerospace, automotive, and heavy machinery industries. Their tailored compositions improve strength and corrosion resistance, supporting critical components like bushings, bearings, and valve guides under extreme conditions. This versatility allows engineered bronze to meet modern industrial demands where durability and precision are essential.

Durability and Longevity: Which Bronze Lasts Longer?

Engineered bronze alloys, designed with precise material compositions and enhanced manufacturing processes, exhibit superior durability and resistance to wear compared to traditional bronze. Their improved tensile strength and corrosion resistance contribute to a longer service life in demanding applications. Traditional bronze, while historically valued for its toughness, typically shows more susceptibility to fatigue and environmental degradation over time.

Cost-Effectiveness: Evaluating Material Investments

Engineered bronze offers enhanced cost-effectiveness compared to traditional bronze by providing superior strength and wear resistance, which reduces maintenance and replacement expenses over time. Its tailored alloy composition minimizes material waste and improves manufacturing efficiency, leading to lower overall production costs. Evaluating long-term durability and performance, engineered bronze often delivers a better return on investment despite an initially higher material price.

Sustainability and Environmental Impact

Engineered bronze alloys often incorporate recycled materials and are designed for longer lifespans, reducing the need for frequent replacements and minimizing resource extraction compared to traditional bronze. These advanced formulations typically result in improved corrosion resistance and mechanical properties, enhancing sustainability by lowering maintenance and waste generation over time. Traditional bronze, while recyclable, usually involves higher energy consumption during smelting and casting, leading to a more significant environmental footprint.

Choosing the Right Bronze for Your Project

Engineered bronze offers enhanced mechanical properties, such as increased strength and wear resistance, making it ideal for high-performance industrial applications compared to traditional bronze, which excels in corrosion resistance and aesthetic appeal. Selecting the right bronze depends on project requirements like load-bearing capacity, environmental conditions, and expected lifespan. Prioritizing factors such as tensile strength, machinability, and alloy composition ensures choosing the optimal bronze type for durability and functionality.

Engineered Bronze vs Traditional Bronze Infographic

materialdif.com

materialdif.com