Statue bronze typically contains a higher copper content mixed with tin and sometimes small amounts of other metals like zinc or lead to enhance durability and achieve detailed sculptural finishes. Coinage bronze, on the other hand, often has a more standardized alloy composition designed for mass production, balancing corrosion resistance and malleability for striking coins. The differing alloy ratios reflect their varied functional requirements, with statue bronze prioritizing aesthetic longevity and coinage bronze emphasizing economic efficiency and wear resistance.

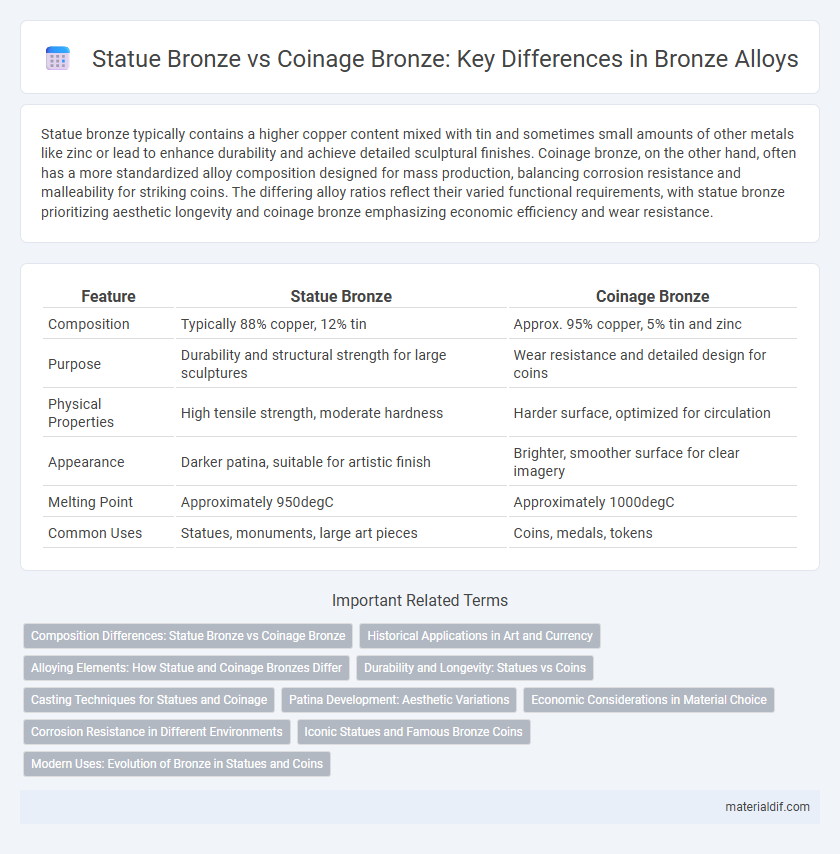

Table of Comparison

| Feature | Statue Bronze | Coinage Bronze |

|---|---|---|

| Composition | Typically 88% copper, 12% tin | Approx. 95% copper, 5% tin and zinc |

| Purpose | Durability and structural strength for large sculptures | Wear resistance and detailed design for coins |

| Physical Properties | High tensile strength, moderate hardness | Harder surface, optimized for circulation |

| Appearance | Darker patina, suitable for artistic finish | Brighter, smoother surface for clear imagery |

| Melting Point | Approximately 950degC | Approximately 1000degC |

| Common Uses | Statues, monuments, large art pieces | Coins, medals, tokens |

Composition Differences: Statue Bronze vs Coinage Bronze

Statue bronze typically contains higher percentages of copper combined with tin and small amounts of zinc or lead, optimizing durability and a smooth casting surface for artistic detailing. Coinage bronze compositions have a standardized ratio, often comprising around 88% copper and 12% tin or zinc, ensuring hardness and resistance to wear for circulation. These distinct alloy compositions reflect their functional requirements, with statue bronze prioritizing workability and finish, while coinage bronze emphasizes longevity and corrosion resistance.

Historical Applications in Art and Currency

Statue bronze, composed primarily of copper and tin with occasional additions of lead or zinc, was historically valued for its durability and ability to capture fine artistic details in sculpture, exemplified by masterpieces from the Renaissance and Ancient Greece. Coinage bronze, often a lower tin and higher copper alloy, prioritized wear resistance and corrosion prevention, making it ideal for currency circulation in the Roman Empire and early modern Europe. The distinct alloy compositions highlight their specialized applications: artistic bronze optimized for aesthetics and casting precision, while coinage bronze balanced cost-effectiveness and longevity in monetary transactions.

Alloying Elements: How Statue and Coinage Bronzes Differ

Statue bronze typically contains higher proportions of tin, ranging from 10 to 20%, which enhances strength and corrosion resistance essential for large-scale sculptures. Coinage bronze, comparatively, includes lower tin content around 5%, combined with zinc and sometimes lead to improve machinability and wear resistance for minting coins. The precise alloying elements and their ratios create distinct mechanical properties tailored to the functional demands of statues versus coins.

Durability and Longevity: Statues vs Coins

Statue bronze typically contains a higher percentage of tin, which enhances its hardness and resistance to wear, making it ideal for large sculptures exposed to environmental elements. Coinage bronze, often alloyed with zinc or other metals, prioritizes durability against frequent handling and corrosion but may slightly compromise hardness to ensure easier minting. Consequently, statues exhibit greater longevity in preserving detailed features over centuries, while coins balance durability with practicality for daily use.

Casting Techniques for Statues and Coinage

Statue bronze typically employs the lost-wax casting method, allowing for intricate details and smooth surfaces critical to large, artistic sculptures. Coinage bronze often uses sand casting or die casting, enabling high-volume production with consistent, thinner designs suitable for currency. Both techniques require precise alloy composition, but statue bronze usually contains higher tin content for durability and finish quality.

Patina Development: Aesthetic Variations

Statue bronze, typically composed with higher copper content and added elements like tin and lead, develops a thick, textured patina that enhances depth and character over time, creating rich green and brown hues. Coinage bronze, often alloyed with more zinc for durability and corrosion resistance, forms a smoother, more uniform patina that preserves metallic luster while showing subtle tonal changes. These patina differences result from the distinct alloy compositions and environmental interactions, influencing the aesthetic appeal in sculpture versus numismatic applications.

Economic Considerations in Material Choice

Statue bronze and coinage bronze differ significantly in composition and economic considerations, with statue bronze typically containing higher copper content and added elements like tin and zinc to enhance durability and aesthetic appeal at a greater cost. Coinage bronze prioritizes cost-efficiency and corrosion resistance, often incorporating lower copper percentages and more zinc to facilitate mass production and maintain affordability for widespread circulation. The balance between material expense and functional requirements dictates the selection, where statue bronze emphasizes longevity and visual impact, while coinage bronze focuses on economic feasibility and production scalability.

Corrosion Resistance in Different Environments

Statue bronze, typically an alloy with higher copper content and added tin, exhibits superior corrosion resistance in outdoor environments, developing a stable patina that protects the surface from further oxidation. Coinage bronze, often formulated with a balance favoring wear resistance and color uniformity, is more susceptible to corrosion when exposed to moisture and acidic conditions, leading to surface degradation over time. Environmental factors like humidity, pollutants, and soil acidity strongly impact the longevity of bronze artifacts, with statue bronze generally outperforming coinage bronze in resisting corrosion in diverse atmospheric and terrestrial settings.

Iconic Statues and Famous Bronze Coins

Iconic statues such as Michelangelo's David and the Statue of Liberty exemplify the use of high-quality bronze alloys renowned for their durability and detailed craftsmanship, highlighting artistic and historical significance. Famous bronze coins, like the Roman sestertius and the Chinese Ban Liang, showcase early advancements in metallurgy, featuring distinct patinas and intricate designs that underscore their role in trade and culture. Both statue bronze and coinage bronze differ in composition and casting techniques, tailored to balance strength, corrosion resistance, and aesthetic appeal for their specific applications.

Modern Uses: Evolution of Bronze in Statues and Coins

Modern statue bronze typically features higher tin content for enhanced durability and corrosion resistance, enabling intricate sculptural details that withstand outdoor environments. Coinage bronze, optimized for mass minting, balances copper, tin, and zinc to ensure hardness, wear resistance, and a smooth finish for circulation. Advances in alloy composition and casting techniques reflect the evolving demands of modern art and currency production, preserving bronze's legacy in both functional and aesthetic applications.

Statue Bronze vs Coinage Bronze Infographic

materialdif.com

materialdif.com