Gunmetal bronze is an alloy primarily composed of copper, tin, and zinc, known for its improved machinability and corrosion resistance, making it ideal for manufacturing guns and marine hardware. Bell metal bronze contains a higher tin content, producing a harder and more resonant alloy commonly used in the casting of bells and musical instruments. The key difference lies in their composition and applications, with gunmetal bronze favoring durability and toughness, while bell metal bronze emphasizes acoustic quality and hardness.

Table of Comparison

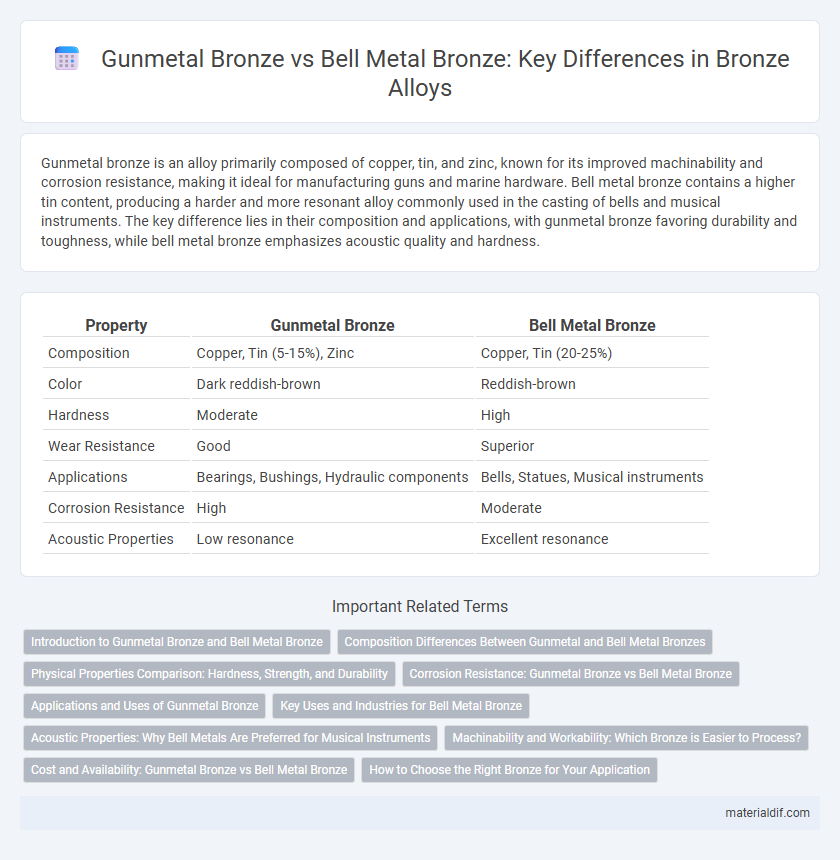

| Property | Gunmetal Bronze | Bell Metal Bronze |

|---|---|---|

| Composition | Copper, Tin (5-15%), Zinc | Copper, Tin (20-25%) |

| Color | Dark reddish-brown | Reddish-brown |

| Hardness | Moderate | High |

| Wear Resistance | Good | Superior |

| Applications | Bearings, Bushings, Hydraulic components | Bells, Statues, Musical instruments |

| Corrosion Resistance | High | Moderate |

| Acoustic Properties | Low resonance | Excellent resonance |

Introduction to Gunmetal Bronze and Bell Metal Bronze

Gunmetal bronze is a durable alloy primarily composed of copper, tin, and zinc, known for its corrosion resistance and machinability, often used in valves, gears, and bearings. Bell metal bronze, consisting mainly of copper and a higher tin content, is valued for its resonant properties, making it ideal for casting bells and musical instruments. The distinct compositions of gunmetal and bell metal result in unique mechanical and acoustic qualities tailored to their specific industrial and artistic applications.

Composition Differences Between Gunmetal and Bell Metal Bronzes

Gunmetal bronze primarily consists of copper, tin, and zinc, with zinc content typically ranging from 5% to 15%, enhancing its toughness and corrosion resistance. Bell metal bronze, on the other hand, contains a higher tin content, usually between 20% to 25%, with minimal or no zinc, which provides greater hardness and resonance ideal for making bells. The presence of zinc in gunmetal reduces brittleness compared to bell metal, which relies on its higher tin concentration for superior tonal quality.

Physical Properties Comparison: Hardness, Strength, and Durability

Gunmetal bronze exhibits higher tensile strength and superior hardness compared to bell metal bronze, making it ideal for applications requiring enhanced wear resistance. Bell metal bronze typically contains a higher tin content, which provides excellent resonance and durability but results in slightly lower mechanical strength. Both alloys demonstrate good corrosion resistance, yet gunmetal's composition offers greater toughness and impact resistance suitable for industrial uses.

Corrosion Resistance: Gunmetal Bronze vs Bell Metal Bronze

Gunmetal bronze exhibits superior corrosion resistance due to its higher copper and tin content combined with small amounts of zinc, making it highly durable in marine environments. Bell metal bronze, with a higher tin concentration and lower zinc content, offers good corrosion resistance but is more prone to oxidation and stress cracking. In comparison, gunmetal bronze provides enhanced longevity and structural integrity in applications requiring exposure to water and corrosive elements.

Applications and Uses of Gunmetal Bronze

Gunmetal bronze, composed primarily of copper, tin, and zinc, is widely used in applications requiring corrosion resistance and high strength, such as marine hardware, valves, and bearings. Its ability to withstand the harsh marine environment makes it ideal for ship propellers, underwater fittings, and pump components. Unlike bell metal bronze, which excels in acoustic properties for musical instruments, gunmetal bronze is favored for mechanical parts demanding durability and wear resistance.

Key Uses and Industries for Bell Metal Bronze

Bell Metal Bronze, an alloy primarily composed of copper and tin, is renowned for its excellent resonating properties, making it ideal for musical instruments such as bells and gongs. Its durability and resistance to corrosion extend its application to marine hardware and architectural fittings. The automotive and aerospace industries also utilize Bell Metal Bronze for components requiring durability combined with acoustic qualities.

Acoustic Properties: Why Bell Metals Are Preferred for Musical Instruments

Gunmetal bronze, typically composed of copper, tin, and zinc, offers high strength and corrosion resistance but produces a duller sound compared to bell metal bronze. Bell metal bronze, consisting of roughly 78% copper and 22% tin, exhibits superior acoustic properties including a bright, resonant tone with excellent sustain, making it the preferred choice for musical instruments such as bells and gongs. The higher tin content in bell metal increases hardness and density, enhancing vibration transmission and sound clarity critical for musical applications.

Machinability and Workability: Which Bronze is Easier to Process?

Gunmetal bronze contains tin, zinc, and sometimes lead, offering superior machinability due to its finely grained structure and lead content that acts as a lubricant during cutting processes. Bell metal bronze, primarily composed of copper and tin with a higher tin content, is harder and more brittle, making it less workable and challenging to machine without causing tool wear or material cracking. For applications requiring easier processing and precision machining, gunmetal bronze is typically preferred over bell metal bronze.

Cost and Availability: Gunmetal Bronze vs Bell Metal Bronze

Gunmetal bronze is generally more cost-effective and widely available due to its simpler alloy composition of primarily copper, tin, and zinc, making it a preferred choice for large-scale industrial applications. Bell metal bronze, characterized by a higher tin content typically around 20-25%, is more expensive and less common, as its specialized properties are ideal for acoustic applications like bells and musical instruments. The higher cost and limited availability of bell metal bronze reflect its niche demand and more complex manufacturing process compared to the more versatile and affordable gunmetal bronze.

How to Choose the Right Bronze for Your Application

Gunmetal Bronze offers superior corrosion resistance and machinability, making it ideal for marine hardware, valves, and bearings exposed to harsh environments. Bell Metal Bronze, known for its high tin content, provides excellent resonance and durability, preferred in musical instruments and sculptures. Consider application requirements such as strength, wear resistance, and acoustic properties when selecting between Gunmetal and Bell Metal Bronze.

Gunmetal Bronze vs Bell Metal Bronze Infographic

materialdif.com

materialdif.com