Industrial quartz is primarily valued for its high purity and durability, making it essential in manufacturing electronics, glass, and silicon chips, whereas gemstone quartz is prized for its aesthetic qualities, clarity, and color variations, used mainly in jewelry and decorative items. The structural composition of both types is chemically similar, but the key difference lies in their applications and visual attributes, with industrial quartz often being more opaque and less visually appealing. Understanding these distinctions helps in selecting the appropriate quartz type for either technological or ornamental purposes.

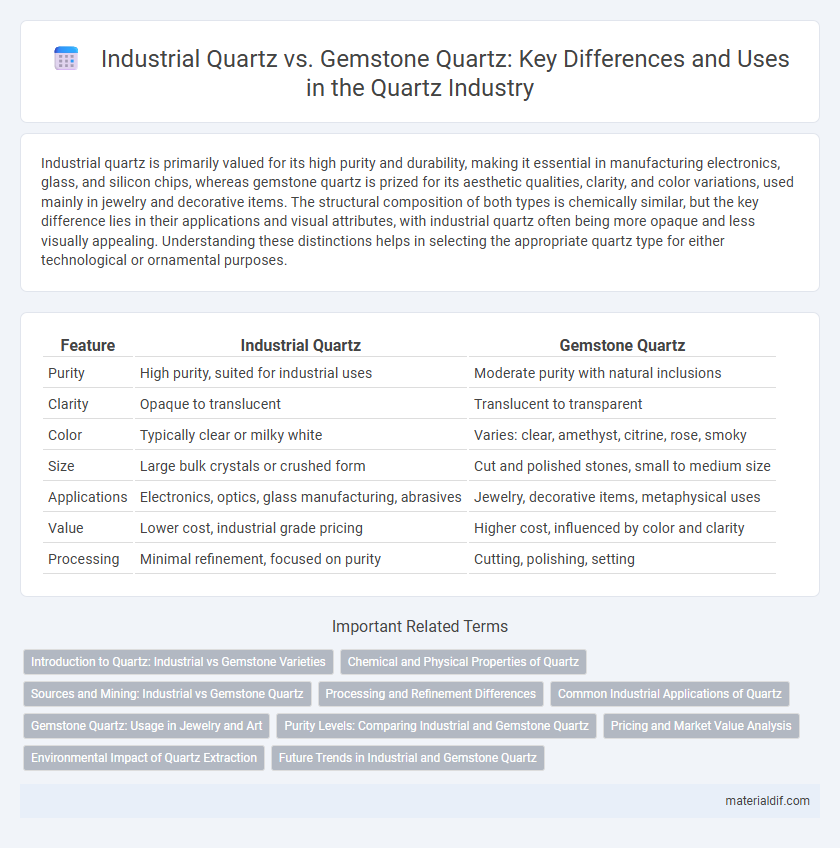

Table of Comparison

| Feature | Industrial Quartz | Gemstone Quartz |

|---|---|---|

| Purity | High purity, suited for industrial uses | Moderate purity with natural inclusions |

| Clarity | Opaque to translucent | Translucent to transparent |

| Color | Typically clear or milky white | Varies: clear, amethyst, citrine, rose, smoky |

| Size | Large bulk crystals or crushed form | Cut and polished stones, small to medium size |

| Applications | Electronics, optics, glass manufacturing, abrasives | Jewelry, decorative items, metaphysical uses |

| Value | Lower cost, industrial grade pricing | Higher cost, influenced by color and clarity |

| Processing | Minimal refinement, focused on purity | Cutting, polishing, setting |

Introduction to Quartz: Industrial vs Gemstone Varieties

Quartz, a crystalline mineral composed primarily of silicon dioxide, exists in both industrial and gemstone varieties distinguished by purity and application. Industrial quartz is valued for its high silica content and durability, making it essential in electronics, glass manufacturing, and construction. Gemstone quartz, including amethyst and citrine, is prized for its clarity, color, and optical properties used in jewelry and ornamental designs.

Chemical and Physical Properties of Quartz

Industrial quartz is primarily valued for its high purity silicon dioxide (SiO2) content, typically exceeding 99.5%, making it ideal for applications in electronics and optics due to its exceptional thermal stability and piezoelectric properties. Gemstone quartz, such as amethyst or citrine, contains trace mineral impurities that influence its color and optical clarity, although it retains the same hexagonal crystal structure and hardness of 7 on the Mohs scale. Both types exhibit excellent chemical resistance and durability, but industrial quartz emphasizes purity and uniformity, whereas gemstone quartz is prized for its aesthetic variations.

Sources and Mining: Industrial vs Gemstone Quartz

Industrial quartz is primarily sourced from large-scale open-pit mining operations in countries like the United States, Brazil, and Madagascar, where purity and size for manufacturing applications are critical. Gemstone quartz, including varieties like amethyst, citrine, and rose quartz, is often mined in smaller quantities from specialized deposits found in places such as Brazil, Uruguay, and Zambia, emphasizing clarity and color for jewelry use. The extraction of industrial quartz focuses on high-volume production to meet demands in electronics, glassmaking, and construction, while gemstone quartz mining targets aesthetic quality and crystal structure for collectors and artisans.

Processing and Refinement Differences

Industrial quartz undergoes rigorous crushing, grinding, and chemical purification to achieve high purity levels essential for electronics, optics, and glass manufacturing. In contrast, gemstone quartz is minimally processed to preserve natural color, clarity, and crystal structure, emphasizing polishing and cutting techniques that enhance aesthetic appeal. The refinement of industrial quartz prioritizes functionality and chemical purity, while gemstone quartz refinement focuses on visual quality and market value.

Common Industrial Applications of Quartz

Industrial quartz, primarily composed of high-purity silicon dioxide, is essential in manufacturing processes such as glassmaking, ceramics, and foundry molds due to its heat resistance and durability. Gemstone quartz, valued for its clarity and color variations, is less commonly used in industrial applications and more often found in jewelry and ornamental pieces. Common industrial applications exploit quartz's chemical inertness and physical stability in electronics, optical instruments, and abrasive materials.

Gemstone Quartz: Usage in Jewelry and Art

Gemstone quartz, prized for its clarity, color variations, and unique crystal formations, is extensively used in jewelry design and artistic creations, offering a versatile alternative to traditional gemstones. Its varieties, such as amethyst, citrine, and rose quartz, provide designers with a broad palette to craft elegant rings, necklaces, and ornamental pieces. Unlike industrial quartz, which is valued for its functional properties in electronics and manufacturing, gemstone quartz emphasizes aesthetic qualities and natural beauty, making it a favorite in artisanal and luxury markets.

Purity Levels: Comparing Industrial and Gemstone Quartz

Industrial quartz typically contains higher levels of impurities such as iron, aluminum, and titanium, which impact its usability in manufacturing processes like electronics and glassmaking. In contrast, gemstone quartz exhibits superior purity with minimal inclusions, enhancing its clarity and value in jewelry applications. Purity levels directly influence the performance and aesthetic appeal of quartz in their respective industrial and gemstone uses.

Pricing and Market Value Analysis

Industrial quartz is primarily valued for its high purity and physical properties, used extensively in electronics, glass manufacturing, and silicon production, making its pricing stable but generally lower compared to gemstone quartz. Gemstone quartz, including varieties like amethyst and citrine, commands higher market prices due to aesthetic appeal, rarity, and demand in the jewelry industry, often fluctuating based on quality, color, and clarity. Market value analysis shows industrial quartz benefits from bulk use and consistency, while gemstone quartz pricing is driven by consumer trends and collector interest.

Environmental Impact of Quartz Extraction

Industrial quartz extraction primarily involves large-scale mining operations that disrupt landscapes and generate significant habitat loss, contributing to soil erosion and water contamination from chemical runoff. Gemstone quartz mining, though smaller in scale, often employs artisanal methods that can lead to localized environmental degradation and improper waste management. Sustainable practices in both types of quartz extraction are critical to minimizing ecological footprints and preserving biodiversity.

Future Trends in Industrial and Gemstone Quartz

Industrial quartz markets are expected to grow significantly due to rising demand in electronics, renewable energy sectors, and advanced manufacturing technologies. Gemstone quartz, driven by evolving consumer preferences and fashion trends, is likely to see increased demand in luxury jewelry and decorative applications. Innovations in synthetic quartz production and sustainable mining practices will shape future trends across both industrial and gemstone quartz segments.

Industrial Quartz vs Gemstone Quartz Infographic

materialdif.com

materialdif.com