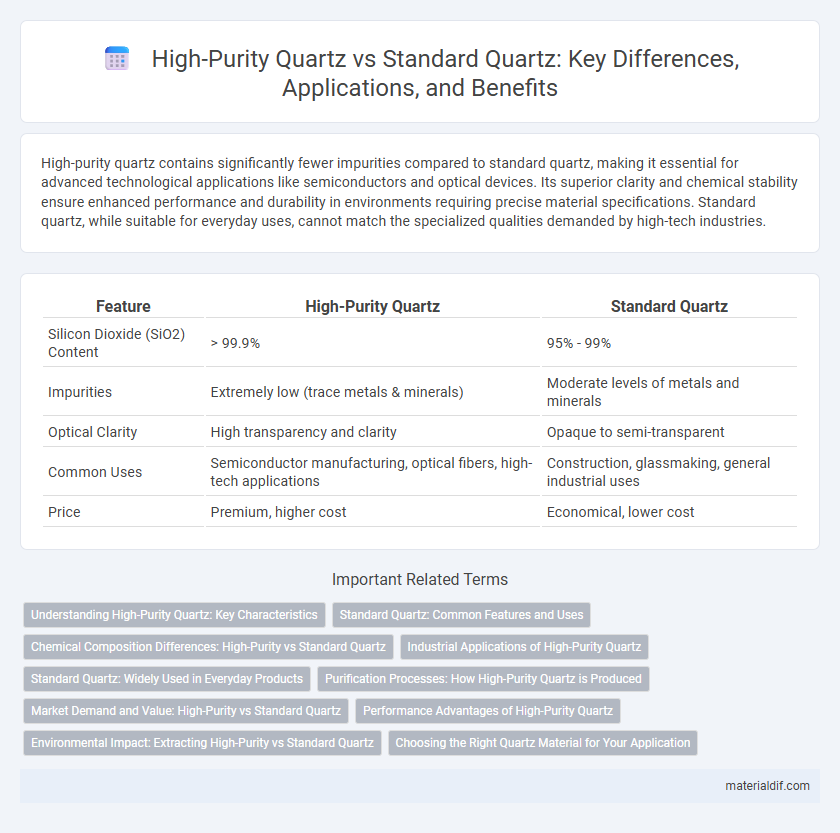

High-purity quartz contains significantly fewer impurities compared to standard quartz, making it essential for advanced technological applications like semiconductors and optical devices. Its superior clarity and chemical stability ensure enhanced performance and durability in environments requiring precise material specifications. Standard quartz, while suitable for everyday uses, cannot match the specialized qualities demanded by high-tech industries.

Table of Comparison

| Feature | High-Purity Quartz | Standard Quartz |

|---|---|---|

| Silicon Dioxide (SiO2) Content | > 99.9% | 95% - 99% |

| Impurities | Extremely low (trace metals & minerals) | Moderate levels of metals and minerals |

| Optical Clarity | High transparency and clarity | Opaque to semi-transparent |

| Common Uses | Semiconductor manufacturing, optical fibers, high-tech applications | Construction, glassmaking, general industrial uses |

| Price | Premium, higher cost | Economical, lower cost |

Understanding High-Purity Quartz: Key Characteristics

High-purity quartz contains over 99.99% silicon dioxide (SiO2), significantly reducing impurities such as iron, aluminum, and titanium compared to standard quartz, which typically has lower purity levels. This exceptional purity enhances thermal stability, optical clarity, and electrical properties, making it essential for semiconductor, optical, and photovoltaic applications. The low impurity content in high-purity quartz prevents contamination during manufacturing processes, ensuring superior performance in high-precision industries.

Standard Quartz: Common Features and Uses

Standard quartz, composed primarily of silicon dioxide (SiO2), exhibits excellent hardness and chemical resistance, making it a versatile material for various industrial applications. Commonly used in glassmaking, construction, and foundry molds, standard quartz provides durability and thermal stability. Its widespread availability and lower cost compared to high-purity quartz make it ideal for general manufacturing processes requiring consistent performance without extreme purity.

Chemical Composition Differences: High-Purity vs Standard Quartz

High-purity quartz contains over 99.99% silicon dioxide (SiO2) with minimal impurities such as aluminum, iron, and titanium, which are typically present in standard quartz at higher concentrations. These trace contaminants in standard quartz can affect its optical and electrical properties, making high-purity quartz essential for semiconductor and optical applications. The chemical composition differences ensure that high-purity quartz delivers superior thermal stability and chemical resistance compared to standard quartz.

Industrial Applications of High-Purity Quartz

High-purity quartz, distinguished by its minimal impurity levels often below 10 ppm, is crucial in semiconductor and optical fiber manufacturing due to its exceptional thermal stability and optical clarity. Unlike standard quartz, which contains higher trace elements affecting performance, high-purity quartz ensures superior electrical insulation and consistent refractive indices essential for high-precision industrial applications. Industries such as electronics, solar photovoltaic cells, and aerospace heavily rely on high-purity quartz to maintain product integrity and optimize operational efficiency.

Standard Quartz: Widely Used in Everyday Products

Standard quartz, primarily composed of silicon dioxide with purity levels around 95-98%, is widely utilized in everyday products such as glass manufacturing, construction materials, and electronics due to its durability and abundance. Its broad availability and cost-effectiveness make it the preferred choice for applications where ultra-high purity is not critical. Compared to high-purity quartz, standard quartz supports mass production in industries relying on reliable mechanical and chemical properties without the need for stringent purity standards.

Purification Processes: How High-Purity Quartz is Produced

High-purity quartz undergoes advanced purification processes, including acid leaching, magnetic separation, and thermal treatment, to remove impurities such as iron, aluminum, and titanium. These methods enhance the SiO2 content to over 99.99%, significantly higher than standard quartz, which typically contains 95-99% silica. Specialized refining techniques ensure the elimination of trace contaminants, making high-purity quartz essential for semiconductor, optical, and solar industries.

Market Demand and Value: High-Purity vs Standard Quartz

High-purity quartz commands a significantly higher market value due to its superior silica content and minimal impurities, making it essential for semiconductor, solar panel, and optical industries. Standard quartz, while abundant and cost-effective, primarily serves construction and decorative purposes with lower technical requirements. The growing demand for advanced electronics and renewable energy technologies drives a rapid increase in high-purity quartz market share globally.

Performance Advantages of High-Purity Quartz

High-purity quartz contains over 99.99% silicon dioxide, significantly reducing contaminants compared to standard quartz, which typically contains 95-99% SiO2. This extreme purity enhances thermal stability and dielectric strength, making high-purity quartz ideal for semiconductor manufacturing and optical applications. Its superior chemical resistance and lower defect density improve overall material performance and device reliability in precision industries.

Environmental Impact: Extracting High-Purity vs Standard Quartz

Extracting high-purity quartz requires more intensive processing and stricter environmental controls than standard quartz, leading to higher energy consumption and increased waste generation. Mining operations for high-purity quartz often involve careful chemical treatments and purification steps that can release hazardous byproducts if not managed properly. In contrast, standard quartz extraction generally has a lower environmental footprint due to less complex processing and raw material refinement.

Choosing the Right Quartz Material for Your Application

High-purity quartz contains over 99.99% silicon dioxide (SiO2) and is essential for applications requiring minimal impurities, such as semiconductor manufacturing and optical components. Standard quartz, with purity levels around 95-99%, suits less sensitive uses like construction and decorative elements where absolute clarity and contamination resistance are not critical. Selecting the right quartz material depends on the application's precision requirements, with high-purity quartz offering superior performance in demanding technological environments.

High-Purity Quartz vs Standard Quartz Infographic

materialdif.com

materialdif.com