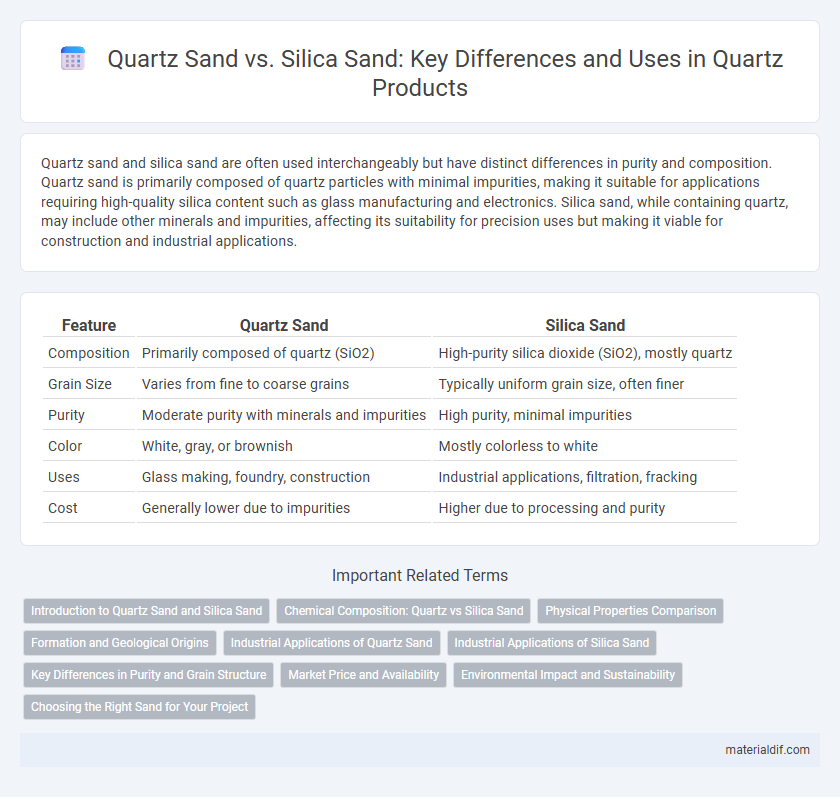

Quartz sand and silica sand are often used interchangeably but have distinct differences in purity and composition. Quartz sand is primarily composed of quartz particles with minimal impurities, making it suitable for applications requiring high-quality silica content such as glass manufacturing and electronics. Silica sand, while containing quartz, may include other minerals and impurities, affecting its suitability for precision uses but making it viable for construction and industrial applications.

Table of Comparison

| Feature | Quartz Sand | Silica Sand |

|---|---|---|

| Composition | Primarily composed of quartz (SiO2) | High-purity silica dioxide (SiO2), mostly quartz |

| Grain Size | Varies from fine to coarse grains | Typically uniform grain size, often finer |

| Purity | Moderate purity with minerals and impurities | High purity, minimal impurities |

| Color | White, gray, or brownish | Mostly colorless to white |

| Uses | Glass making, foundry, construction | Industrial applications, filtration, fracking |

| Cost | Generally lower due to impurities | Higher due to processing and purity |

Introduction to Quartz Sand and Silica Sand

Quartz sand primarily consists of high-purity quartz grains, making it ideal for industrial uses such as glass manufacturing and foundry molds. Silica sand, a broader category, contains various forms of silicon dioxide and may include impurities, affecting its suitability for specific applications. Both sands are essential in construction and filtration but differ significantly in composition and industrial utility.

Chemical Composition: Quartz vs Silica Sand

Quartz sand primarily consists of crystalline silicon dioxide (SiO2), exhibiting high purity and uniform chemical composition. Silica sand also contains silicon dioxide but may include impurities such as iron oxide, aluminum oxide, and other minerals affecting its chemical properties. The distinct purity levels in quartz sand make it preferable for applications requiring high chemical resistance and optical clarity compared to more variable silica sand.

Physical Properties Comparison

Quartz sand and silica sand differ primarily in their purity levels, with quartz sand consisting mostly of quartz crystals and silica sand containing higher percentages of silicon dioxide (SiO2). Quartz sand exhibits greater hardness (approximately 7 on the Mohs scale) and higher density, making it more resistant to abrasion and wear compared to typical silica sand varieties. The particle shape of quartz sand tends to be more angular and coarse, which enhances its performance in filtration and construction applications relative to the smoother, rounded grains of silica sand.

Formation and Geological Origins

Quartz sand primarily forms from the weathering and erosion of quartz-rich rocks like granite and sandstone, resulting in high-purity grains composed almost entirely of quartz. Silica sand, while often containing quartz, also includes other silica minerals and may originate from a broader range of geological sources such as quartzite, sandstone, and certain sedimentary deposits. The geological origins of quartz sand emphasize crystalline quartz from igneous and metamorphic processes, whereas silica sand represents a more diverse mineralogical composition derived from varied sedimentary environments.

Industrial Applications of Quartz Sand

Quartz sand, prized for its high purity and angular grain shape, serves as a critical raw material in the glass manufacturing, foundry casting, and construction industries. Its consistent chemical composition and refractoriness make it ideal for producing high-quality glass, molding cores, and filler materials in concrete. Unlike silica sand, which may contain impurities, quartz sand guarantees superior performance and durability in demanding industrial applications.

Industrial Applications of Silica Sand

Silica sand, a high-purity form of quartz sand composed primarily of silicon dioxide (SiO2), is extensively used in industrial applications such as glass manufacturing, foundry molds, water filtration, and hydraulic fracturing. Its chemical stability, high melting point, and uniform grain size make it essential for producing durable glass products, casting metal parts with precision, and filtering contaminants from water. Compared to general quartz sand, silica sand's controlled composition and purity levels enhance performance in critical industrial processes, ensuring efficiency and product consistency.

Key Differences in Purity and Grain Structure

Quartz sand exhibits higher purity than silica sand, typically containing over 99% silicon dioxide (SiO2) with minimal impurities, which enhances its suitability for applications requiring ultra-pure material. The grain structure of quartz sand is more angular and rigid due to its crystalline nature, providing superior strength and chemical resistance compared to the often more rounded and softer grains of silica sand. These differences in purity and grain morphology directly impact the performance of each type in industrial uses such as glassmaking, foundry casting, and water filtration.

Market Price and Availability

Quartz sand generally commands a higher market price compared to silica sand due to its purity and specific industrial applications. The availability of quartz sand is more limited, as it requires more extensive processing to achieve the desired grade for electronics and optical uses. Silica sand is abundantly available and widely used in construction, glass manufacturing, and foundries, contributing to its lower pricing and greater market presence.

Environmental Impact and Sustainability

Quartz sand and silica sand both play crucial roles in industrial applications but differ significantly in environmental impact and sustainability. Quartz sand extraction often results in lower ecological disruption due to less intensive mining processes, whereas silica sand mining can lead to habitat destruction and increased carbon emissions from extraction and processing. Sustainable practices in quartz sand mining emphasize reduced water usage, reclamation efforts, and minimizing air pollution, making it a more environmentally responsible option compared to traditional silica sand extraction methods.

Choosing the Right Sand for Your Project

Quartz sand and silica sand differ primarily in composition and purity; quartz sand is a natural form of silicon dioxide often containing impurities, while silica sand is a highly refined version with a higher percentage of pure silicon dioxide. Selecting the right sand depends on the project's requirements, such as grain size, purity level, and intended use in construction, glass manufacturing, or filtration systems. Ensuring the sand meets specific technical standards is crucial for durability, performance, and overall effectiveness in industrial applications.

Quartz Sand vs Silica Sand Infographic

materialdif.com

materialdif.com