Sintered stone and quartz both offer durable, non-porous surfaces ideal for countertops, but sintered stone is manufactured using natural minerals subjected to extreme heat and pressure, resulting in enhanced resistance to scratches, heat, and UV rays. Quartz countertops are engineered from crushed quartz mixed with resin, providing a wide range of colors and patterns but can be more susceptible to heat damage and discoloration over time. Choosing between sintered stone and quartz depends on the specific needs for durability, maintenance, and aesthetic preferences in interior design.

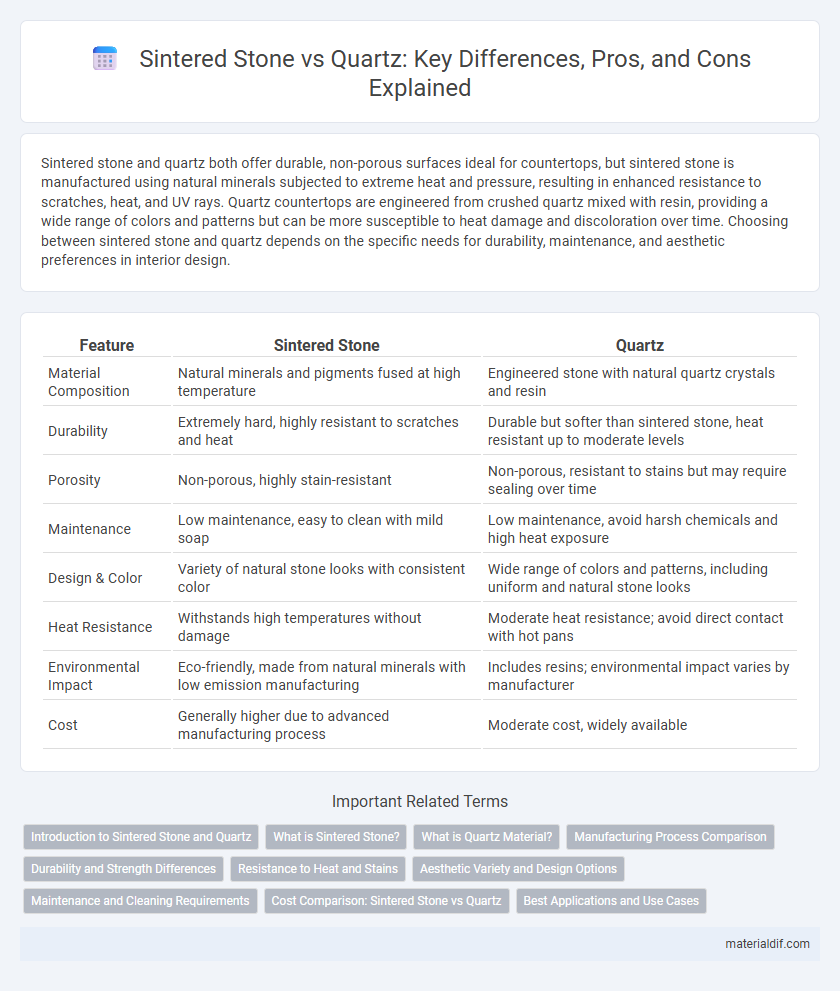

Table of Comparison

| Feature | Sintered Stone | Quartz |

|---|---|---|

| Material Composition | Natural minerals and pigments fused at high temperature | Engineered stone with natural quartz crystals and resin |

| Durability | Extremely hard, highly resistant to scratches and heat | Durable but softer than sintered stone, heat resistant up to moderate levels |

| Porosity | Non-porous, highly stain-resistant | Non-porous, resistant to stains but may require sealing over time |

| Maintenance | Low maintenance, easy to clean with mild soap | Low maintenance, avoid harsh chemicals and high heat exposure |

| Design & Color | Variety of natural stone looks with consistent color | Wide range of colors and patterns, including uniform and natural stone looks |

| Heat Resistance | Withstands high temperatures without damage | Moderate heat resistance; avoid direct contact with hot pans |

| Environmental Impact | Eco-friendly, made from natural minerals with low emission manufacturing | Includes resins; environmental impact varies by manufacturer |

| Cost | Generally higher due to advanced manufacturing process | Moderate cost, widely available |

Introduction to Sintered Stone and Quartz

Sintered stone is an engineered material made from natural minerals subjected to extreme heat and pressure, resulting in a durable, non-porous surface ideal for countertops and flooring. Quartz, another engineered stone, consists of approximately 90% ground quartz combined with resins and pigments, offering a wide variety of colors and patterns with excellent durability and stain resistance. Both materials outperform natural stone in terms of maintenance and longevity, making them popular choices in modern interior design.

What is Sintered Stone?

Sintered stone is an engineered material produced by compacting natural minerals such as feldspar, quartz, and kaolin at high temperature and pressure, creating a durable, non-porous surface. Unlike quartz, which is primarily composed of crushed quartz crystals bound with resin, sintered stone offers enhanced heat resistance and scratch durability, making it ideal for kitchen countertops and outdoor applications. This innovative manufacturing process results in a highly dense, stain-resistant surface with excellent UV stability and minimal maintenance requirements.

What is Quartz Material?

Quartz material is an engineered stone composed of approximately 90-95% natural quartz crystals combined with resin and pigments, creating a durable and non-porous surface. Its manufacturing process involves bonding crushed quartz with polymer resins under high pressure and heat, resulting in a highly resilient material ideal for countertops and flooring. Quartz surfaces offer exceptional resistance to stains, scratches, and heat compared to natural stones and some sintered stones.

Manufacturing Process Comparison

Sintered stone is produced by compacting natural minerals under extreme heat and pressure, employing advanced technology that mimics natural geological processes, without the need for resins or additives. Quartz surfaces are engineered by blending approximately 90-95% natural quartz crystals with polymer resins and pigments through a controlled manufacturing process involving compression and curing. This fundamental difference in manufacturing techniques impacts material characteristics such as durability, porosity, and heat resistance, making sintered stone highly resistant to UV and thermal shocks, while quartz offers greater design flexibility due to its resin components.

Durability and Strength Differences

Sintered stone offers superior hardness and scratch resistance compared to quartz, making it highly durable for heavy-use surfaces. Quartz, composed of natural quartz mixed with resin, is less heat resistant and more prone to chipping under extreme conditions. Both materials provide excellent strength, but sintered stone's compact manufacturing process results in enhanced resistance to impact and wear.

Resistance to Heat and Stains

Sintered stone exhibits superior resistance to heat, withstanding temperatures up to 1200degF without damage, compared to quartz, which can tolerate heat up to 150degC before risking discoloration or cracking. Quartz surfaces offer excellent stain resistance due to their non-porous resin and natural quartz composition, but sintered stone's ultra-dense structure enhances its ability to resist stains from acids and oils more effectively. Both materials maintain durability in kitchen environments, yet sintered stone provides a higher threshold for heat exposure and chemical resistance.

Aesthetic Variety and Design Options

Sintered stone offers a broader aesthetic variety with its natural stone-like textures and patterns, mimicking marble, granite, and slate with exceptional realism. Quartz surfaces provide consistent color and pattern options, often featuring engineered designs with high durability and vibrant hues. Both materials excel in design flexibility, but sintered stone leads in authentic stone appearances while quartz is favored for uniformity and customization.

Maintenance and Cleaning Requirements

Sintered stone requires minimal maintenance due to its non-porous surface, resisting stains and scratches without the need for sealing. Quartz surfaces also offer low maintenance with a non-porous composition that prevents bacterial growth and simplifies cleaning with mild soap and water. Both materials demand routine cleaning but differ in heat resistance, with sintered stone generally enduring higher temperatures without damage.

Cost Comparison: Sintered Stone vs Quartz

Sintered stone generally costs between $60 and $100 per square foot, while quartz typically ranges from $50 to $120 per square foot, depending on brand and quality. Installation expenses for sintered stone may be higher due to its hardness and specialized cutting requirements. Comparing these costs, quartz offers more budget-friendly options, whereas sintered stone provides a premium pricing tier justified by its enhanced durability and heat resistance.

Best Applications and Use Cases

Sintered stone offers exceptional resistance to heat, scratches, and UV rays, making it ideal for outdoor kitchens, facades, and heavy-use countertops. Quartz is best suited for indoor countertops and bathrooms due to its non-porous surface, easy maintenance, and wide color variety. Both materials are durable, but sintered stone excels in high-traffic or exposed areas, while quartz provides better design flexibility and stain resistance indoors.

Sintered Stone vs Quartz Infographic

materialdif.com

materialdif.com