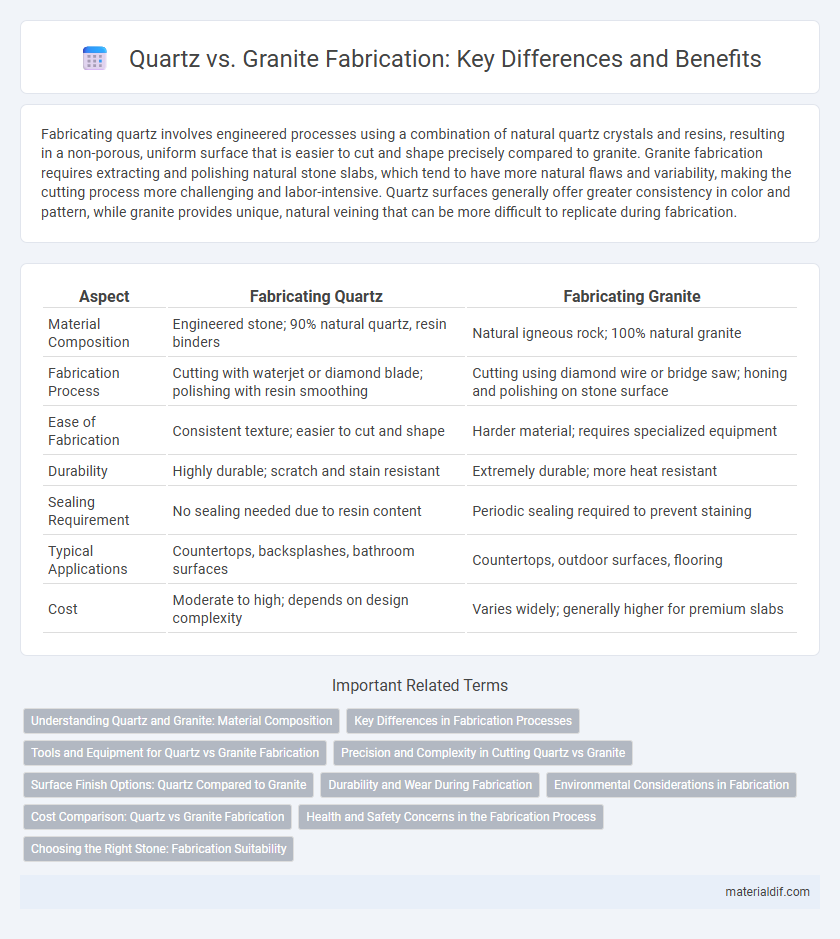

Fabricating quartz involves engineered processes using a combination of natural quartz crystals and resins, resulting in a non-porous, uniform surface that is easier to cut and shape precisely compared to granite. Granite fabrication requires extracting and polishing natural stone slabs, which tend to have more natural flaws and variability, making the cutting process more challenging and labor-intensive. Quartz surfaces generally offer greater consistency in color and pattern, while granite provides unique, natural veining that can be more difficult to replicate during fabrication.

Table of Comparison

| Aspect | Fabricating Quartz | Fabricating Granite |

|---|---|---|

| Material Composition | Engineered stone; 90% natural quartz, resin binders | Natural igneous rock; 100% natural granite |

| Fabrication Process | Cutting with waterjet or diamond blade; polishing with resin smoothing | Cutting using diamond wire or bridge saw; honing and polishing on stone surface |

| Ease of Fabrication | Consistent texture; easier to cut and shape | Harder material; requires specialized equipment |

| Durability | Highly durable; scratch and stain resistant | Extremely durable; more heat resistant |

| Sealing Requirement | No sealing needed due to resin content | Periodic sealing required to prevent staining |

| Typical Applications | Countertops, backsplashes, bathroom surfaces | Countertops, outdoor surfaces, flooring |

| Cost | Moderate to high; depends on design complexity | Varies widely; generally higher for premium slabs |

Understanding Quartz and Granite: Material Composition

Quartz countertops consist primarily of engineered stone, combining approximately 90% natural quartz crystals with resin and pigments to create a non-porous, durable surface resistant to stains and scratches. Granite is a natural igneous rock composed mainly of quartz, feldspar, and mica, featuring a porous texture that requires sealing to prevent moisture and stain penetration. Understanding these material compositions is essential for fabricators to determine cutting, polishing techniques, and maintenance requirements specific to each stone type.

Key Differences in Fabrication Processes

Fabricating quartz involves engineered processes where crushed quartz is combined with resin and pigments, allowing for consistent color and pattern control, while granite fabrication requires cutting and polishing natural stone, resulting in unique, variable patterns. Quartz fabrication uses advanced machinery for precise shaping and curing under heat and pressure, whereas granite fabrication relies on traditional wet cutting and grinding techniques. The engineered nature of quartz leads to less porosity and easier fabrication, contrasting with granite's natural hardness and variability that demand specialized tools and expertise.

Tools and Equipment for Quartz vs Granite Fabrication

Quartz fabrication requires diamond-tipped blades and water-cooled saws to prevent overheating and maintain precision, while granite fabrication demands heavier-duty machinery such as bridge saws and polishing machines to handle its denser composition. Both materials necessitate the use of CNC routers for shaping, but quartz's engineered nature allows for more consistent cutting without frequent tool replacements. Dust extraction systems are essential in both processes due to the fine silica dust generated, with enhanced filtration needed for quartz to mitigate health risks.

Precision and Complexity in Cutting Quartz vs Granite

Fabricating quartz involves advanced precision techniques due to its engineered composition, allowing for more intricate and consistent cuts compared to natural granite, which exhibits variable hardness and grain patterns. Quartz fabrication benefits from controlled manufacturing processes that enhance cutting accuracy and reduce chipping risks, while granite's natural variation demands skilled craftsmanship and specialized tools to achieve complex shapes. The precision required in quartz cutting enables detailed designs and seamless edges, surpassing the limitations typically encountered with granite slabs.

Surface Finish Options: Quartz Compared to Granite

Quartz offers a wider range of surface finish options compared to granite, including polished, honed, leathered, and matte finishes, allowing for greater customization in texture and shine. Unlike granite, quartz finishes maintain their appearance longer due to the engineered material's non-porous and stain-resistant properties. The consistency in quartz fabrication ensures uniform surface finishes, while granite's natural variation can result in less predictable visual outcomes.

Durability and Wear During Fabrication

Quartz offers superior durability compared to granite, resisting chipping and cracking during fabrication due to its engineered composition and consistent density. Granite's natural variability can lead to weaknesses, making it more susceptible to wear and breakage when cut or polished. Fabricators favor quartz for its ease of handling and lower risk of damage, reducing waste and improving project efficiency.

Environmental Considerations in Fabrication

Fabricating quartz involves less environmental impact compared to granite due to its engineered composition, which reduces the need for extensive quarrying associated with natural stone extraction. Quartz fabrication typically generates lower dust emissions and uses less water, contributing to improved workplace safety and resource conservation. Granite fabrication requires significant energy consumption and waste management efforts because of its natural variability and heavier processing demands.

Cost Comparison: Quartz vs Granite Fabrication

Quartz fabrication generally incurs higher costs compared to granite due to the advanced technology and precision required for engineered stone processing. Granite fabrication involves natural stone cutting and polishing, which tends to be less expensive but may result in more waste material. The price difference is influenced by fabrication complexity, material sourcing, and labor, with quartz often reflecting premium pricing for consistency and customization options.

Health and Safety Concerns in the Fabrication Process

Fabricating quartz poses significant health and safety risks due to the high crystalline silica content, which releases hazardous respirable silica dust during cutting and grinding, leading to silicosis and other respiratory diseases. In contrast, granite fabrication generates lower levels of silica dust but still requires rigorous dust control measures and personal protective equipment (PPE) to minimize inhalation risks. Effective ventilation systems, water suppression, and proper PPE are critical in both processes to protect workers from long-term health hazards related to airborne particulate exposure.

Choosing the Right Stone: Fabrication Suitability

Fabricating quartz offers consistent patterns and lower porosity, making it highly suitable for applications requiring durability and stain resistance, while granite requires specialized tools due to its hardness but provides unique natural variations and superior heat resistance. Quartz fabrication allows for precise molding and seamless designs, ideal for modern countertops and intricate shapes, whereas granite's fabrication demands careful handling to prevent chipping and ensure edge integrity. Selecting the right stone depends on balancing fabrication complexity, aesthetic preferences, and functional requirements like maintenance and surface resilience.

Fabricating Quartz vs Fabricating Granite Infographic

materialdif.com

materialdif.com