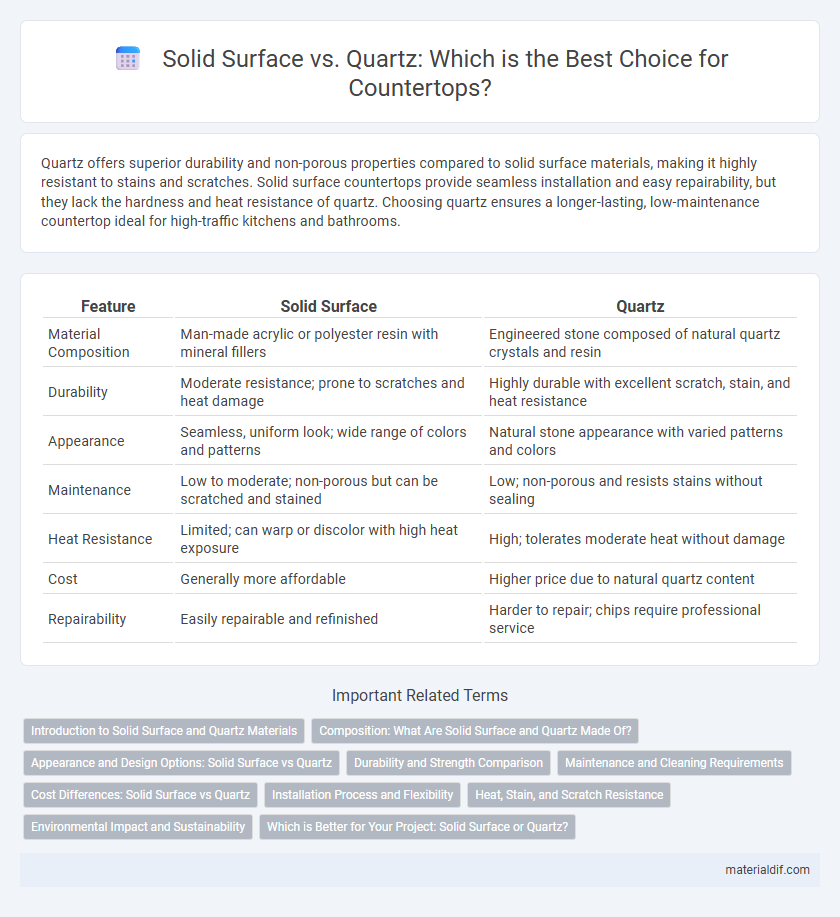

Quartz offers superior durability and non-porous properties compared to solid surface materials, making it highly resistant to stains and scratches. Solid surface countertops provide seamless installation and easy repairability, but they lack the hardness and heat resistance of quartz. Choosing quartz ensures a longer-lasting, low-maintenance countertop ideal for high-traffic kitchens and bathrooms.

Table of Comparison

| Feature | Solid Surface | Quartz |

|---|---|---|

| Material Composition | Man-made acrylic or polyester resin with mineral fillers | Engineered stone composed of natural quartz crystals and resin |

| Durability | Moderate resistance; prone to scratches and heat damage | Highly durable with excellent scratch, stain, and heat resistance |

| Appearance | Seamless, uniform look; wide range of colors and patterns | Natural stone appearance with varied patterns and colors |

| Maintenance | Low to moderate; non-porous but can be scratched and stained | Low; non-porous and resists stains without sealing |

| Heat Resistance | Limited; can warp or discolor with high heat exposure | High; tolerates moderate heat without damage |

| Cost | Generally more affordable | Higher price due to natural quartz content |

| Repairability | Easily repairable and refinished | Harder to repair; chips require professional service |

Introduction to Solid Surface and Quartz Materials

Solid surface materials consist of a blend of acrylic or polyester resins combined with natural minerals, creating a non-porous, seamless surface ideal for countertops and sinks. Quartz surfaces are engineered stone products made from approximately 90-95% natural quartz particles bonded with resin, offering exceptional durability and resistance to stains and scratches. Both materials feature customizable designs and colors, but quartz typically provides greater hardness and heat resistance compared to solid surface counterparts.

Composition: What Are Solid Surface and Quartz Made Of?

Solid surface countertops are primarily composed of a blend of acrylic or polyester resins combined with natural minerals like alumina trihydrate, creating a non-porous, seamless surface favored for its uniform appearance. Quartz countertops consist mostly of engineered stone, blending approximately 90-95% natural quartz crystals with resin binders and pigments to enhance durability, stain resistance, and color variety. The distinct compositions influence properties such as hardness, maintenance requirements, and resistance to heat and scratches, making quartz generally harder and more resilient than solid surface materials.

Appearance and Design Options: Solid Surface vs Quartz

Quartz countertops offer a wide range of colors and patterns, closely mimicking natural stone with consistent veining and texture, making them ideal for modern and elegant designs. Solid surface materials provide seamless integration and a matte finish with more uniform color options, allowing for custom shapes and built-in sinks without visible joints. Design flexibility in quartz is enhanced by its durability and gloss, while solid surface excels in customizable forms and smooth, non-porous surfaces perfect for contemporary aesthetics.

Durability and Strength Comparison

Quartz countertops exhibit superior durability compared to solid surface materials due to their composition of natural quartz crystals bonded with resin, providing enhanced resistance to scratches, heat, and stains. Solid surface countertops, typically made from acrylic or polyester resins, offer moderate strength but are more susceptible to surface scratches and heat damage. Both materials resist moisture effectively, but quartz's inherent hardness contributes to a longer lifespan and better impact resistance in high-traffic kitchen environments.

Maintenance and Cleaning Requirements

Quartz surfaces require minimal maintenance due to their non-porous nature, resisting stains and bacteria without needing sealing. Solid surface materials, while also low-maintenance, can be more susceptible to scratches and heat damage, requiring gentle cleaning with mild soap and water. Regular wiping and avoiding abrasive cleaners help preserve the finish of both surfaces, but quartz offers greater ease in long-term upkeep.

Cost Differences: Solid Surface vs Quartz

Quartz countertops generally have a higher upfront cost compared to solid surface materials due to their durability and natural stone components. Solid surface options tend to be more budget-friendly, with prices typically ranging from $35 to $65 per square foot, while quartz can cost between $50 and $120 per square foot. Maintenance expenses for quartz are usually lower over time, as its non-porous nature resists staining and requires less frequent sealing than solid surface countertops.

Installation Process and Flexibility

Quartz countertops offer a more straightforward installation process compared to solid surface materials, as quartz slabs are prefabricated and require precise cutting and sealing on-site to ensure durability. Solid surface countertops provide greater flexibility during installation due to their thermoformable properties, allowing for seamless integration of curved edges and custom shapes. This adaptability makes solid surfaces ideal for unique designs, whereas quartz excels in projects favoring uniformity and structural strength.

Heat, Stain, and Scratch Resistance

Quartz surfaces offer superior heat resistance compared to solid surfaces, withstanding temperatures up to 300degF without damage. Both materials exhibit excellent stain resistance due to their non-porous nature, but quartz is more resistant to harsh chemicals and acids. Scratch resistance is higher in quartz, thanks to its harder mineral composition, making it less prone to surface abrasions over time.

Environmental Impact and Sustainability

Quartz countertops are engineered from natural quartz combined with resins and pigments, resulting in a durable but less recyclable product compared to solid surface materials made primarily from renewable and recyclable polymers. Solid surface countertops often have a lower environmental impact due to their ability to be repaired and reshaped, extending lifespan and reducing waste in landfills. The production of quartz involves energy-intensive mining and processing, whereas solid surface manufacturing can incorporate recycled content and generate fewer emissions, enhancing overall sustainability.

Which is Better for Your Project: Solid Surface or Quartz?

Quartz surfaces offer superior durability and resistance to scratches, stains, and heat compared to solid surface materials, making them ideal for high-traffic kitchen countertops. Solid surfaces provide seamless joints and a more affordable option with easy repair and customization, better suited for bathrooms and lighter-use areas. Evaluating your project's needs for durability, maintenance, and budget helps determine whether quartz or solid surface delivers the best balance of performance and aesthetics.

Solid Surface vs Quartz Infographic

materialdif.com

materialdif.com