Resin-bonded quartz offers enhanced durability and non-porous surfaces, making it highly resistant to stains and scratches compared to cement-bonded quartz. Cement-bonded quartz typically provides a more affordable option but may be more prone to cracking and requires regular sealing to maintain its appearance. Choosing between these materials depends on the balance between budget, durability, and maintenance preferences for your project.

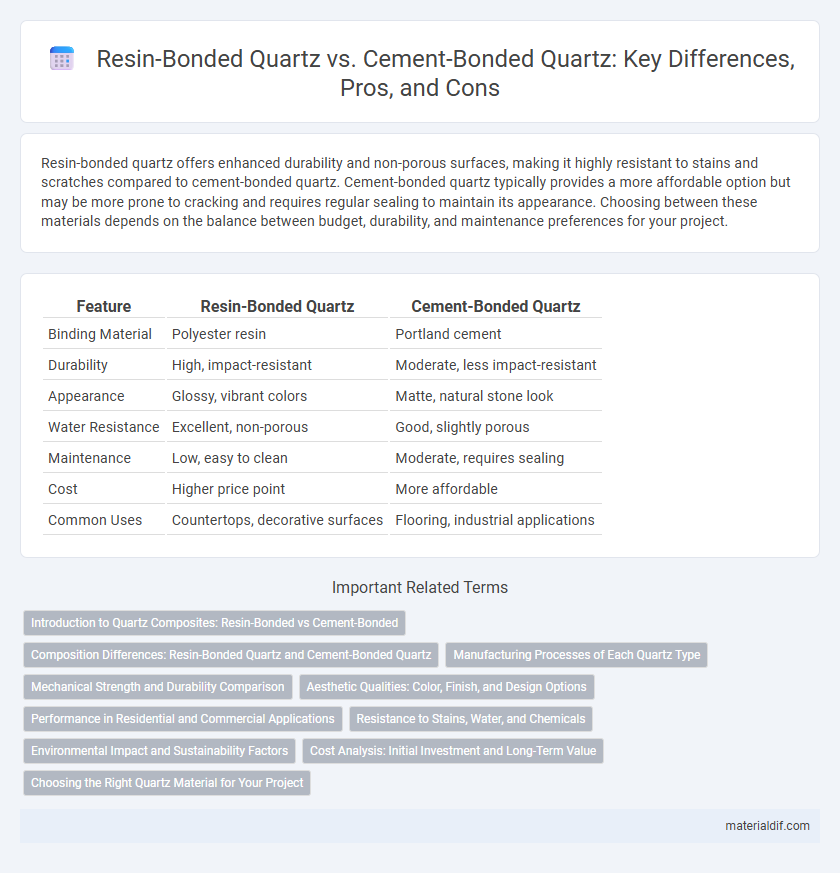

Table of Comparison

| Feature | Resin-Bonded Quartz | Cement-Bonded Quartz |

|---|---|---|

| Binding Material | Polyester resin | Portland cement |

| Durability | High, impact-resistant | Moderate, less impact-resistant |

| Appearance | Glossy, vibrant colors | Matte, natural stone look |

| Water Resistance | Excellent, non-porous | Good, slightly porous |

| Maintenance | Low, easy to clean | Moderate, requires sealing |

| Cost | Higher price point | More affordable |

| Common Uses | Countertops, decorative surfaces | Flooring, industrial applications |

Introduction to Quartz Composites: Resin-Bonded vs Cement-Bonded

Resin-bonded quartz composites consist of crushed quartz aggregates bound by a polymer resin, offering high durability, low porosity, and a wide range of colors and finishes suitable for countertops and flooring. Cement-bonded quartz composites use a cementitious binder mixed with quartz aggregates, providing excellent heat resistance and a more natural stone appearance, often preferred for outdoor applications and heavy-duty surfaces. Understanding the differences in bonding agents helps select the appropriate quartz composite based on performance requirements, aesthetic preferences, and installation environments.

Composition Differences: Resin-Bonded Quartz and Cement-Bonded Quartz

Resin-bonded quartz consists of natural quartz crystals combined with a polymer resin, creating a non-porous and durable surface ideal for countertops. Cement-bonded quartz incorporates quartz aggregates mixed with cement as the binder, resulting in a more porous and heavier material commonly used in flooring and outdoor applications. The primary composition difference lies in the binding agents: synthetic resin for enhanced flexibility and stain resistance versus cement for structural strength and moisture absorption.

Manufacturing Processes of Each Quartz Type

Resin-bonded quartz is manufactured by mixing crushed quartz aggregates with a polymer resin binder, then curing the mixture under controlled heat and pressure to create a durable, non-porous surface. Cement-bonded quartz involves blending quartz aggregates with Portland cement, water, and additives, followed by a hydraulic setting process and curing that results in a harder, more porous material. The choice of binder directly influences the production techniques, physical properties, and application suitability of each quartz type.

Mechanical Strength and Durability Comparison

Resin-bonded quartz exhibits superior mechanical strength due to its high resin content, which enhances flexibility and impact resistance, making it ideal for heavy-use surfaces. Cement-bonded quartz, while less flexible, provides enhanced durability against high temperatures and chemical exposure, suitable for industrial applications. The mechanical strength of resin-bonded quartz typically ranges between 40-60 MPa flexural strength, whereas cement-bonded quartz offers higher compressive strength but lower tensile strength, affecting its performance in different environments.

Aesthetic Qualities: Color, Finish, and Design Options

Resin-bonded quartz offers superior aesthetic qualities with a wide range of vibrant color options and polished or matte finishes that enhance its visual appeal. Cement-bonded quartz typically presents more muted tones and a rougher texture, limiting design versatility. The resin binder in resin-bonded quartz allows for intricate patterns and a smoother, more consistent surface, making it ideal for modern, high-end interior designs.

Performance in Residential and Commercial Applications

Resin-bonded quartz offers higher durability and stain resistance compared to cement-bonded quartz, making it ideal for both residential kitchens and high-traffic commercial spaces. Cement-bonded quartz, while more cost-effective, tends to have lower mechanical strength and increased porosity, which can affect its longevity in demanding environments. Performance-wise, resin-bonded quartz provides superior non-porous surfaces that resist bacteria and scratching, enhancing its appeal in upscale residential and commercial applications.

Resistance to Stains, Water, and Chemicals

Resin-bonded quartz offers superior resistance to stains, water, and chemicals due to its non-porous surface and strong resin matrix, making it highly durable for kitchen and bathroom applications. Cement-bonded quartz, while robust, tends to be more porous, increasing susceptibility to staining and water absorption, which can lead to chemical damage over time. Choosing resin-bonded quartz ensures enhanced longevity and easier maintenance compared to cement-bonded alternatives.

Environmental Impact and Sustainability Factors

Resin-bonded quartz surfaces feature a polymer binder that often contains synthetic chemicals, contributing to lower recyclability and potential off-gassing concerns compared to cement-bonded quartz, which uses a mineral-based binder with generally higher environmental compatibility. Cement-bonded quartz typically exhibits better sustainability credentials due to its natural composition, lower embodied energy, and enhanced recyclability at end-of-life stages. The choice between resin-bonded and cement-bonded quartz significantly impacts carbon footprint and ecological toxicity, making cement-based options preferable for eco-conscious construction and interior design projects.

Cost Analysis: Initial Investment and Long-Term Value

Resin-bonded quartz typically requires a higher initial investment due to synthetic adhesives and more precise manufacturing processes, while cement-bonded quartz offers a lower upfront cost driven by traditional cement binding methods. Over time, resin-bonded quartz delivers greater long-term value through enhanced durability, stain resistance, and lower maintenance requirements, reducing replacement and repair expenses. Cement-bonded quartz may incur higher lifecycle costs owing to susceptibility to cracking and wear, despite its affordability at purchase.

Choosing the Right Quartz Material for Your Project

Resin-bonded quartz offers superior durability and a smoother finish, making it ideal for high-traffic areas and modern aesthetics, while cement-bonded quartz provides enhanced strength and heat resistance, suitable for outdoor or industrial applications. Selecting the right quartz material depends on factors such as project location, exposure to elements, and desired surface texture. Thorough evaluation of resin and cement bonding properties ensures optimal performance and longevity tailored to specific design requirements.

Resin-Bonded Quartz vs Cement-Bonded Quartz Infographic

materialdif.com

materialdif.com