Reconstituted quartz consists of crushed natural quartz particles mixed with resin or binders to create engineered stone surfaces, offering enhanced durability and uniformity for countertops and flooring. Fused quartz is made by melting natural quartz crystals at extremely high temperatures into a glassy, non-crystalline material known for excellent thermal shock resistance and optical clarity. While reconstituted quartz excels in aesthetic customization and surface hardness, fused quartz is preferred in high-precision optics and semiconductor manufacturing due to its purity and thermal stability.

Table of Comparison

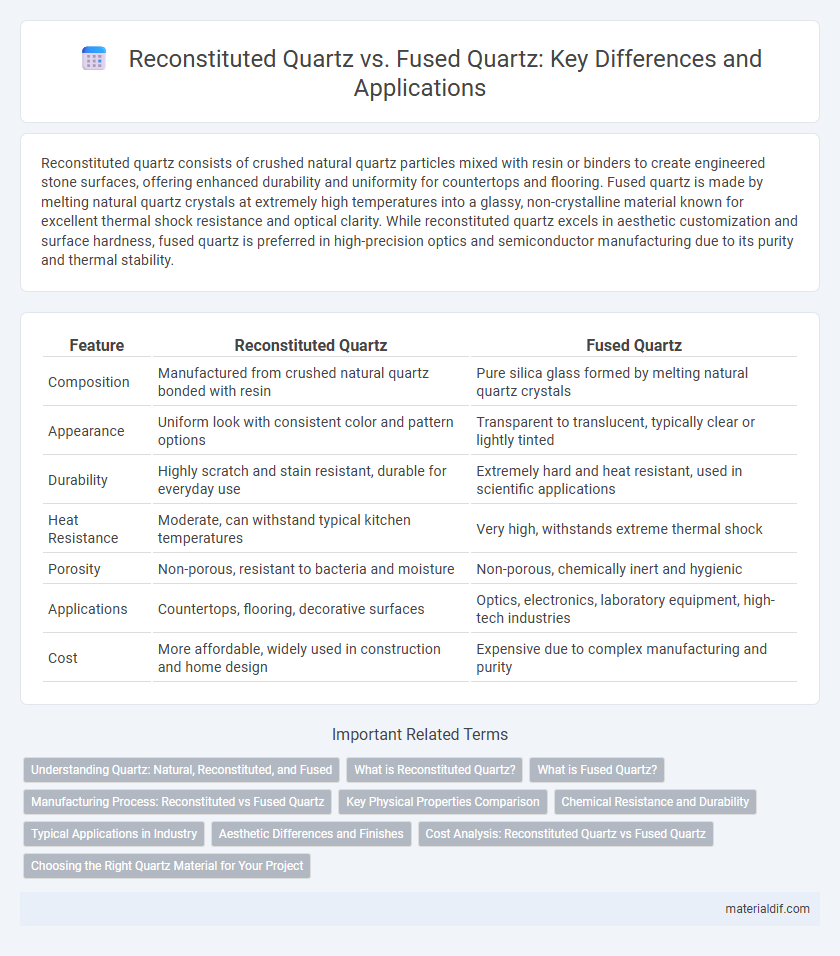

| Feature | Reconstituted Quartz | Fused Quartz |

|---|---|---|

| Composition | Manufactured from crushed natural quartz bonded with resin | Pure silica glass formed by melting natural quartz crystals |

| Appearance | Uniform look with consistent color and pattern options | Transparent to translucent, typically clear or lightly tinted |

| Durability | Highly scratch and stain resistant, durable for everyday use | Extremely hard and heat resistant, used in scientific applications |

| Heat Resistance | Moderate, can withstand typical kitchen temperatures | Very high, withstands extreme thermal shock |

| Porosity | Non-porous, resistant to bacteria and moisture | Non-porous, chemically inert and hygienic |

| Applications | Countertops, flooring, decorative surfaces | Optics, electronics, laboratory equipment, high-tech industries |

| Cost | More affordable, widely used in construction and home design | Expensive due to complex manufacturing and purity |

Understanding Quartz: Natural, Reconstituted, and Fused

Reconstituted quartz is engineered by binding crushed natural quartz with resin, offering versatility in surface applications and consistent patterns, while fused quartz is produced by melting high-purity quartz crystals at extreme temperatures, resulting in a nearly flawless, non-porous material with superior thermal and optical properties. Natural quartz forms through geological processes, providing inherent durability and unique crystalline structures. Understanding these distinctions aids in selecting the appropriate quartz type for specific industrial, architectural, or decorative uses.

What is Reconstituted Quartz?

Reconstituted quartz is a engineered material created by crushing natural quartz crystals into fine particles and combining them with resin and pigments to form durable slabs. It offers enhanced consistency, design versatility, and improved resistance to stains and scratches compared to natural quartz. Unlike fused quartz, which is produced by melting high-purity quartz sand at extremely high temperatures, reconstituted quartz is manufactured through a binding and pressing process that preserves the natural appearance while optimizing structural stability.

What is Fused Quartz?

Fused quartz is a type of glass made by melting high-purity quartz crystals at extremely high temperatures, resulting in a non-crystalline, amorphous solid with exceptional thermal and optical properties. It offers superior resistance to thermal shock, low thermal expansion, and excellent transparency across a wide range of wavelengths, making it ideal for applications in optics, semiconductors, and high-temperature environments. Unlike reconstituted quartz, fused quartz has a uniform molecular structure without impurities, ensuring high performance in precision and industrial uses.

Manufacturing Process: Reconstituted vs Fused Quartz

Reconstituted quartz is manufactured by grinding natural quartz crystals into a fine powder and then binding them with resin or other adhesives before curing and shaping, allowing for customizable sizes and shapes. Fused quartz is produced by melting high-purity quartz crystals at extremely high temperatures above 1,700degC, resulting in a homogeneous, non-crystalline glass with superior thermal and optical properties. The manufacturing process of fused quartz yields a material with higher purity and structural uniformity compared to reconstituted quartz, which contains polymer binders and may have variable mechanical strengths.

Key Physical Properties Comparison

Reconstituted quartz is engineered by binding crushed quartz particles with resin or cement, resulting in a material that exhibits enhanced uniformity and customizable hardness, while fused quartz is produced by melting high-purity natural quartz at temperatures above 1700degC, offering superior thermal stability and low thermal expansion. Reconstituted quartz typically has a Mohs hardness of 6-7 and moderate resistance to chemical corrosion, whereas fused quartz reaches a hardness around 7, with exceptional resistance to thermal shock and chemical inertness. The density of reconstituted quartz ranges from 2.3 to 2.5 g/cm3, compared to fused quartz's density of approximately 2.2 g/cm3, impacting their suitability for different industrial applications requiring specific mechanical or thermal properties.

Chemical Resistance and Durability

Reconstituted quartz exhibits high chemical resistance due to its engineered composition, making it less prone to stains and corrosion from acids and alkalis compared to fused quartz, which is pure silicon dioxide. Fused quartz offers superior thermal stability and durability at extreme temperatures, but can be more susceptible to mechanical damage under abrasive conditions. Selecting between reconstituted and fused quartz depends on the application's exposure to chemicals or thermal stress, with reconstituted quartz preferred for chemical resistance and fused quartz for high-temperature durability.

Typical Applications in Industry

Reconstituted quartz is commonly used in optical components, laboratory instruments, and high-precision electronics due to its uniformity and cost-effectiveness. Fused quartz finds typical applications in semiconductor manufacturing, UV optical systems, and high-temperature-resistant components because of its superior thermal stability and purity. Both materials serve crucial roles in industries requiring precise thermal and optical properties.

Aesthetic Differences and Finishes

Reconstituted quartz offers a wide range of vibrant color options and consistent patterns due to its engineered nature, making it ideal for decorative surfaces requiring uniform aesthetics. Fused quartz, formed by melting pure silica, exhibits a more translucent and glass-like appearance with a smooth, natural finish often favored in optical and high-temperature applications. Surface finishes for reconstituted quartz include polished, honed, and textured, while fused quartz typically features a pristine, ultra-smooth finish with minimal optical distortion.

Cost Analysis: Reconstituted Quartz vs Fused Quartz

Reconstituted quartz typically costs less than fused quartz due to its manufacturing process involving crushed natural quartz combined with resin, which reduces raw material expenses. Fused quartz undergoes a high-temperature melting process of pure silicon dioxide, making it more expensive but offering superior thermal and optical properties. For applications prioritizing budget and aesthetic versatility, reconstituted quartz is a cost-effective choice, whereas fused quartz is preferred for high-performance needs despite its higher price point.

Choosing the Right Quartz Material for Your Project

Reconstituted quartz offers enhanced durability and design versatility due to its composite nature, making it ideal for countertops and decorative surfaces requiring uniform appearance and high resistance to stains and scratches. Fused quartz, derived from pure silica melted at extreme temperatures, excels in high-temperature applications and optical clarity, making it suitable for scientific instruments and electronic components. Selecting the right quartz material depends on project requirements such as mechanical strength, thermal stability, and aesthetic preferences.

Reconstituted Quartz vs Fused Quartz Infographic

materialdif.com

materialdif.com