Crystallized quartz is a naturally formed mineral with a well-ordered atomic structure, exhibiting distinct crystal patterns and high piezoelectric properties. Fused quartz, in contrast, is a man-made glass produced by melting high-purity silica, resulting in an amorphous solid without a crystalline structure but with excellent thermal and chemical resistance. Both types of quartz serve unique purposes: crystallized quartz is essential for electronic oscillators, while fused quartz is preferred for optical fibers and laboratory equipment due to its durability and clarity.

Table of Comparison

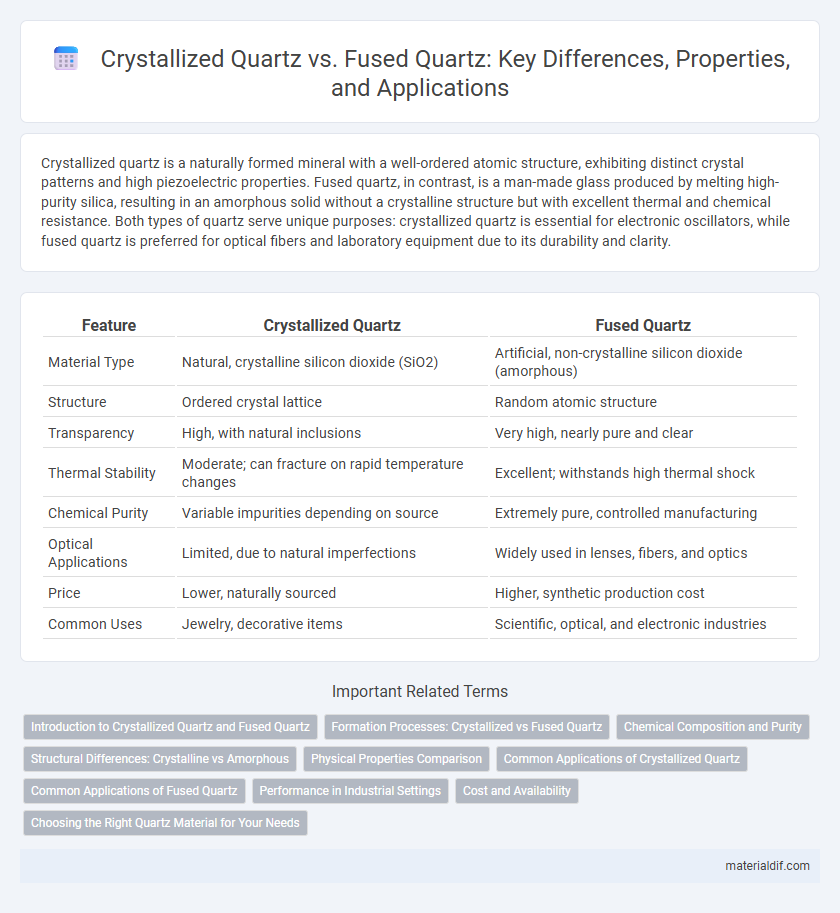

| Feature | Crystallized Quartz | Fused Quartz |

|---|---|---|

| Material Type | Natural, crystalline silicon dioxide (SiO2) | Artificial, non-crystalline silicon dioxide (amorphous) |

| Structure | Ordered crystal lattice | Random atomic structure |

| Transparency | High, with natural inclusions | Very high, nearly pure and clear |

| Thermal Stability | Moderate; can fracture on rapid temperature changes | Excellent; withstands high thermal shock |

| Chemical Purity | Variable impurities depending on source | Extremely pure, controlled manufacturing |

| Optical Applications | Limited, due to natural imperfections | Widely used in lenses, fibers, and optics |

| Price | Lower, naturally sourced | Higher, synthetic production cost |

| Common Uses | Jewelry, decorative items | Scientific, optical, and electronic industries |

Introduction to Crystallized Quartz and Fused Quartz

Crystallized quartz is a naturally occurring mineral composed of silicon dioxide, characterized by its well-ordered atomic structure and distinct hexagonal crystals. Fused quartz, on the other hand, is an engineered glass made by melting high-purity quartz crystals at extremely high temperatures, resulting in an amorphous, non-crystalline solid. Both materials exhibit exceptional thermal stability and optical clarity, but their structural differences influence their applications in electronics, optics, and materials science.

Formation Processes: Crystallized vs Fused Quartz

Crystallized quartz forms naturally through the slow cooling and solidification of silica-rich magma, allowing atoms to arrange into a highly ordered, crystalline structure. In contrast, fused quartz is manufactured by melting high-purity silica sand at temperatures above 2000degC, then rapidly cooling it to create an amorphous, non-crystalline solid. The distinct formation processes result in crystallized quartz exhibiting well-defined crystal lattices, while fused quartz possesses superior thermal shock resistance and optical clarity due to its glassy matrix.

Chemical Composition and Purity

Crystallized quartz, also known as natural quartz, consists primarily of silica (SiO2) in a highly ordered, crystalline structure, often containing trace mineral impurities that affect its purity. Fused quartz is manufactured by melting high-purity silica sand at temperatures exceeding 2000degC, resulting in an amorphous, non-crystalline structure with a higher chemical purity due to the removal of most impurities. The chemical composition of both forms remains silicon dioxide, but fused quartz typically achieves superior purity levels, making it essential for applications requiring minimal contamination.

Structural Differences: Crystalline vs Amorphous

Crystallized quartz features a well-ordered atomic lattice forming a repeating crystalline structure, which gives it distinct optical and mechanical properties. Fused quartz, on the other hand, lacks this long-range order, existing as an amorphous solid with a random atomic arrangement, resulting in higher thermal shock resistance and optical clarity. These structural differences significantly influence their applications in electronics, optics, and industrial manufacturing.

Physical Properties Comparison

Crystallized quartz, also known as natural quartz, exhibits a highly ordered atomic structure with a Mohs hardness of 7 and excellent piezoelectric properties. Fused quartz, an amorphous form produced by melting natural quartz, has superior thermal shock resistance and an extremely low coefficient of thermal expansion around 0.5 x 10^-6 /degC. While crystallized quartz is brittle and prone to cleavage along crystallographic planes, fused quartz is more durable under high-stress environments due to its isotropic nature and lack of grain boundaries.

Common Applications of Crystallized Quartz

Crystallized quartz is widely used in precision instruments, such as oscillators and resonators in electronic devices, due to its piezoelectric properties and stable frequency characteristics. It is commonly found in watches, clocks, and radio transmitters, where accurate timekeeping and signal processing are essential. These applications leverage the natural crystalline structure of quartz to maintain consistent performance under varying environmental conditions.

Common Applications of Fused Quartz

Fused quartz is widely used in semiconductor manufacturing due to its high purity, low thermal expansion, and excellent thermal shock resistance. Its applications include optical fibers, laboratory equipment, and high-temperature furnace components, where minimal contamination and strong mechanical properties are critical. Unlike crystallized quartz, fused quartz offers superior transparency to ultraviolet light, making it essential for photolithography and UV optics.

Performance in Industrial Settings

Crystallized quartz exhibits superior thermal stability and mechanical strength, making it ideal for high-precision industrial applications requiring consistent performance under extreme temperatures. Fused quartz offers excellent optical clarity and low thermal expansion, which is crucial for semiconductor manufacturing and laser technology where dimensional stability is essential. Both materials perform reliably in demanding environments, but quartz selection depends on specific industrial requirements such as thermal resistance or optical purity.

Cost and Availability

Crystallized quartz, formed naturally through geological processes, tends to be more expensive and less readily available due to its rarity and the time required for its formation. Fused quartz, produced synthetically by melting high-purity silica, is generally more cost-effective and widely available for industrial applications, offering consistent quality and purity. The manufacturing process of fused quartz allows for large-scale production, making it the preferred choice in technologies demanding high-performance optical and electronic materials.

Choosing the Right Quartz Material for Your Needs

Crystallized quartz offers superior optical clarity and thermal stability, making it ideal for high-precision applications like scientific instruments and high-quality lenses. Fused quartz, known for its exceptional purity and resistance to thermal shock, is preferred in environments requiring durability and high-temperature resistance, such as semiconductor manufacturing and UV optics. Selecting the right quartz depends on balancing clarity, thermal tolerance, and mechanical strength to suit the specific operational demands.

Crystallized Quartz vs Fused Quartz Infographic

materialdif.com

materialdif.com