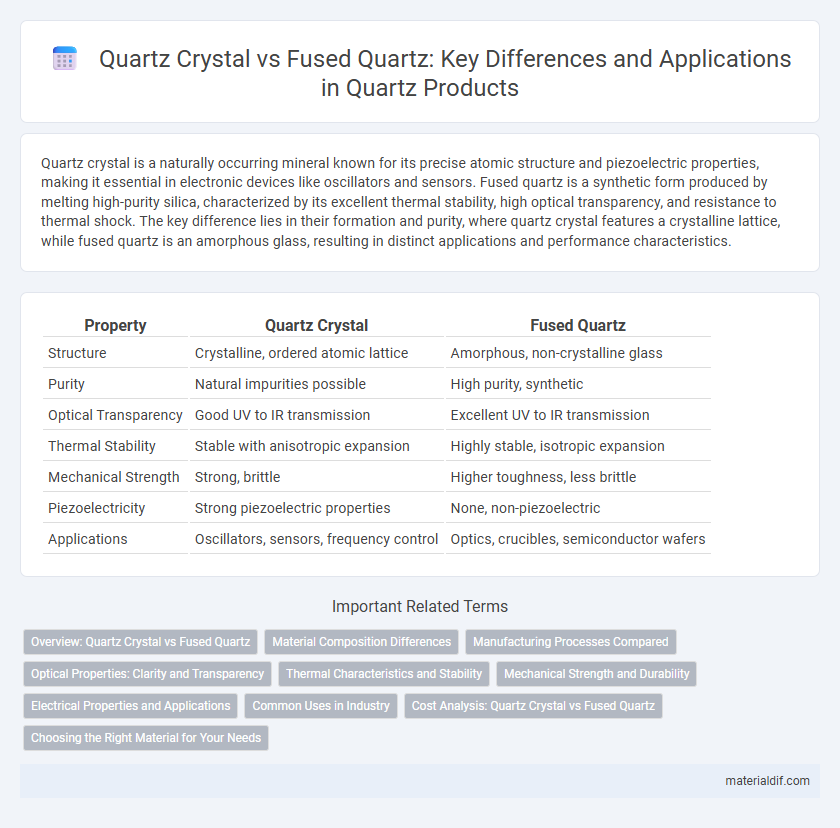

Quartz crystal is a naturally occurring mineral known for its precise atomic structure and piezoelectric properties, making it essential in electronic devices like oscillators and sensors. Fused quartz is a synthetic form produced by melting high-purity silica, characterized by its excellent thermal stability, high optical transparency, and resistance to thermal shock. The key difference lies in their formation and purity, where quartz crystal features a crystalline lattice, while fused quartz is an amorphous glass, resulting in distinct applications and performance characteristics.

Table of Comparison

| Property | Quartz Crystal | Fused Quartz |

|---|---|---|

| Structure | Crystalline, ordered atomic lattice | Amorphous, non-crystalline glass |

| Purity | Natural impurities possible | High purity, synthetic |

| Optical Transparency | Good UV to IR transmission | Excellent UV to IR transmission |

| Thermal Stability | Stable with anisotropic expansion | Highly stable, isotropic expansion |

| Mechanical Strength | Strong, brittle | Higher toughness, less brittle |

| Piezoelectricity | Strong piezoelectric properties | None, non-piezoelectric |

| Applications | Oscillators, sensors, frequency control | Optics, crucibles, semiconductor wafers |

Overview: Quartz Crystal vs Fused Quartz

Quartz crystal is a naturally occurring mineral with a well-ordered atomic structure and piezoelectric properties, commonly used in electronic oscillators and frequency control devices. Fused quartz, also known as fused silica, is a synthetic glass made by melting high-purity silica, offering superior thermal stability, optical transparency, and low thermal expansion for applications like semiconductor manufacturing and high-precision optics. Both materials are essential in technology but differ significantly in structure, manufacturing, and performance characteristics.

Material Composition Differences

Quartz crystal is a naturally occurring mineral composed primarily of silicon dioxide (SiO2) arranged in a well-ordered, crystalline lattice that imparts piezoelectric properties. Fused quartz, on the other hand, is a synthetic amorphous form of silicon dioxide produced by melting high-purity quartz crystals, resulting in a non-crystalline, glassy structure with superior thermal and optical properties. The key material composition difference lies in the crystalline arrangement of quartz crystal versus the random atomic structure of fused quartz, affecting their mechanical, optical, and electrical characteristics.

Manufacturing Processes Compared

Quartz crystal forms naturally through geological processes over millions of years, characterized by a well-ordered atomic structure crucial for piezoelectric applications. Fused quartz is manufactured by melting high-purity quartz sand at temperatures above 1700degC, resulting in an amorphous, non-crystalline glass with superior thermal shock resistance. The manufacturing of quartz crystal involves precision cutting and polishing to retain its crystalline integrity, while fused quartz focuses on controlled melting and rapid cooling to prevent crystallization.

Optical Properties: Clarity and Transparency

Quartz crystal exhibits natural clarity with slight variations caused by impurities and internal fractures, resulting in high but sometimes inconsistent transparency. Fused quartz boasts superior optical properties due to its synthetic production process, offering nearly flawless clarity and exceptional transparency across a broad wavelength range from ultraviolet to infrared. This makes fused quartz ideal for precision optical applications requiring minimal light scattering and high transmission efficiency.

Thermal Characteristics and Stability

Quartz crystal exhibits excellent thermal stability with a low coefficient of thermal expansion around 13.7 x 10-6 /degC, making it ideal for precision oscillators and frequency control devices. Fused quartz offers superior thermal shock resistance and a near-zero thermal expansion coefficient approximately 0.5 x 10-6 /degC, ensuring minimal dimensional changes under extreme temperature fluctuations. Both materials maintain high thermal stability, but fused quartz is preferred in applications demanding exceptional heat resistance and structural integrity.

Mechanical Strength and Durability

Quartz crystal exhibits superior mechanical strength due to its well-ordered atomic lattice, making it highly resistant to deformation under stress. In contrast, fused quartz, an amorphous form of silicon dioxide, offers enhanced durability by resisting thermal shock and chemical corrosion more effectively than crystalline quartz. The combination of structural rigidity in quartz crystal and the toughness of fused quartz determines their suitability for applications requiring specific mechanical and environmental resilience.

Electrical Properties and Applications

Quartz crystal exhibits piezoelectric properties, enabling it to generate an electric charge under mechanical stress, which is essential for precise frequency control in oscillators and resonators. Fused quartz, an amorphous form of silicon dioxide, lacks piezoelectricity but demonstrates superior electrical insulation, high dielectric strength, and low electrical conductivity, making it ideal for use in high-voltage insulators and semiconductor manufacturing. The distinct electrical behaviors of quartz crystal and fused quartz determine their specialized applications in electronics and industrial processes.

Common Uses in Industry

Quartz crystal is widely used in electronic devices for its precise frequency control in oscillators and resonators, essential in telecommunications, watches, and GPS technology. Fused quartz is favored in semiconductor manufacturing, optical instruments, and high-temperature applications due to its exceptional thermal stability, chemical resistance, and optical clarity. Both materials play pivotal roles in industrial settings, with quartz crystal dominating in frequency-sensitive components and fused quartz excelling in environments requiring durability and transparency.

Cost Analysis: Quartz Crystal vs Fused Quartz

Quartz crystal typically incurs higher costs due to its natural formation, precise cutting, and polishing processes, making it ideal for applications requiring high piezoelectric properties. Fused quartz, produced through melting and rapid cooling of high-purity silica, offers lower manufacturing expenses and excellent thermal stability, favoring uses in optical and semiconductor industries. Cost analysis reveals fused quartz as a more economical choice for large-scale production, while quartz crystal remains valuable for specialized applications demanding superior crystalline structure.

Choosing the Right Material for Your Needs

Quartz crystal offers natural piezoelectric properties essential for precise frequency control in electronic components, making it ideal for oscillators and resonators. Fused quartz, a synthetic glass formed by melting natural quartz, provides superior thermal stability and optical clarity, suitable for high-temperature applications and optical instruments. Selecting between quartz crystal and fused quartz depends on the need for electrical resonance versus thermal resistance and optical performance.

Quartz Crystal vs Fused Quartz Infographic

materialdif.com

materialdif.com