Resin-bonded quartz combines natural quartz crystals with a resin adhesive, creating a durable, non-porous surface ideal for countertops and flooring. Pure quartz, on the other hand, consists of 100% natural quartz crystals, offering superior hardness but requiring sealing to prevent stains and damage. Resin-bonded quartz provides enhanced stain resistance and lower maintenance compared to pure quartz, making it a popular choice for busy households.

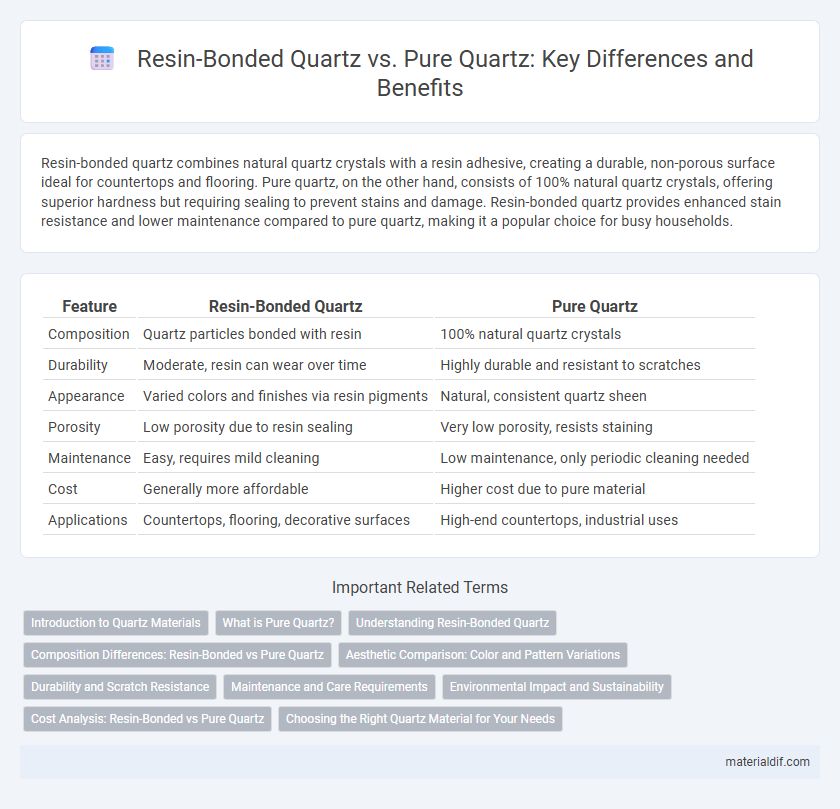

Table of Comparison

| Feature | Resin-Bonded Quartz | Pure Quartz |

|---|---|---|

| Composition | Quartz particles bonded with resin | 100% natural quartz crystals |

| Durability | Moderate, resin can wear over time | Highly durable and resistant to scratches |

| Appearance | Varied colors and finishes via resin pigments | Natural, consistent quartz sheen |

| Porosity | Low porosity due to resin sealing | Very low porosity, resists staining |

| Maintenance | Easy, requires mild cleaning | Low maintenance, only periodic cleaning needed |

| Cost | Generally more affordable | Higher cost due to pure material |

| Applications | Countertops, flooring, decorative surfaces | High-end countertops, industrial uses |

Introduction to Quartz Materials

Quartz materials consist primarily of silicon dioxide crystals, offering durability and aesthetic appeal in various applications. Resin-bonded quartz combines natural quartz particles with resin adhesives, enhancing flexibility and impact resistance compared to pure quartz, which contains 99% natural quartz and offers superior hardness and thermal stability. Choosing between resin-bonded and pure quartz depends on balancing cost, strength, and desired surface properties for specific uses.

What is Pure Quartz?

Pure quartz is a natural mineral composed of silicon dioxide (SiO2) with a crystalline structure, renowned for its durability, hardness, and resistance to heat and chemicals. Unlike resin-bonded quartz, pure quartz surfaces are made entirely of natural quartz without any synthetic resin binders, resulting in a denser and more heat-resistant material. This 100% natural composition makes pure quartz highly suitable for applications requiring superior strength and longevity, such as countertops and industrial uses.

Understanding Resin-Bonded Quartz

Resin-bonded quartz combines natural quartz crystals with durable resin binders, enhancing its strength and flexibility compared to pure quartz, which consists almost entirely of natural quartz mineral. This composite structure offers increased resistance to stains and impacts, making resin-bonded quartz ideal for countertops and surfaces requiring low maintenance and high durability. Understanding resin-bonded quartz involves recognizing its engineered formation, which integrates up to 93% quartz with polymers to create a non-porous and consistent material.

Composition Differences: Resin-Bonded vs Pure Quartz

Resin-bonded quartz consists of approximately 90-95% natural quartz crystals combined with resin and polymer binders, enhancing flexibility and impact resistance. Pure quartz, on the other hand, is composed of nearly 100% quartz with minimal or no added resins, resulting in a harder, denser surface. The resin content in resin-bonded quartz improves adhesion and color consistency, while pure quartz emphasizes durability and natural stone appearance.

Aesthetic Comparison: Color and Pattern Variations

Resin-bonded quartz surfaces offer a wider range of color and pattern variations due to the ability to mix pigments and binders, creating consistent and customizable designs ideal for tailored aesthetics. Pure quartz, composed entirely of natural quartz crystals, exhibits more subtle and natural color variations with intricate, organic patterns that vary from slab to slab, providing unique and authentic visual appeal. The choice between resin-bonded and pure quartz depends on the desired balance between customizable uniformity and natural, one-of-a-kind pattern aesthetics.

Durability and Scratch Resistance

Resin-bonded quartz surfaces combine natural quartz particles with resin, providing enhanced flexibility but slightly lower durability compared to pure quartz, which is composed almost entirely of natural quartz crystals. Pure quartz exhibits superior scratch resistance due to its dense, crystalline structure and lack of resin components that can be more susceptible to surface damage. For applications demanding long-lasting durability and high resistance to scratches, pure quartz is the optimal choice, while resin-bonded quartz offers improved versatility and design options.

Maintenance and Care Requirements

Resin-bonded quartz surfaces require regular cleaning with non-abrasive, pH-balanced cleaners to prevent resin degradation and maintain their glossy finish, while avoiding harsh chemicals that can cause discoloration or surface damage. Pure quartz, being natural stone, demands less maintenance but benefits from periodic sealing to protect against stains and moisture infiltration, ensuring long-term durability. Both materials benefit from prompt spill cleanup and gentle cleaning routines to preserve their appearance and structural integrity over time.

Environmental Impact and Sustainability

Resin-bonded quartz combines crushed quartz with resin binders, which may release volatile organic compounds (VOCs) during production, impacting indoor air quality and the environment. Pure quartz surfaces, composed mainly of natural quartz without resin additives, exhibit lower emissions and can be more easily recycled, enhancing sustainability credentials. Selecting pure quartz reduces reliance on synthetic materials and favors eco-friendlier manufacturing practices in the countertop industry.

Cost Analysis: Resin-Bonded vs Pure Quartz

Resin-bonded quartz offers a cost-effective alternative to pure quartz by combining natural quartz aggregates with resin binders, significantly reducing material and installation expenses. Pure quartz, composed almost entirely of high-purity quartz crystals, commands a higher price due to its superior durability and minimal resin content. Budget-conscious projects benefit from resin-bonded quartz's lower upfront cost while balancing considerations of longevity and maintenance expenses.

Choosing the Right Quartz Material for Your Needs

Resin-bonded quartz combines natural quartz particles with resin binders, offering enhanced flexibility, stain resistance, and affordability compared to pure quartz, which is composed of nearly 100% natural quartz providing superior durability and heat resistance. Selecting the right quartz material depends on your specific application, budget, and desired aesthetic; resin-bonded quartz suits decorative and light-use surfaces, while pure quartz excels in high-traffic areas requiring long-term resilience. Evaluating factors like maintenance requirements, environmental exposure, and mechanical stress ensures optimal performance and longevity in your quartz choice.

Resin-Bonded Quartz vs Pure Quartz Infographic

materialdif.com

materialdif.com