Engineered quartz offers greater durability and stain resistance compared to natural stone, making it ideal for high-traffic areas like kitchens and bathrooms. Unlike natural stone, engineered quartz is non-porous and requires minimal maintenance while providing a consistent appearance with a wide range of colors and patterns. Its combination of aesthetic appeal and practical benefits has made engineered quartz a popular alternative to traditional natural stone surfaces.

Table of Comparison

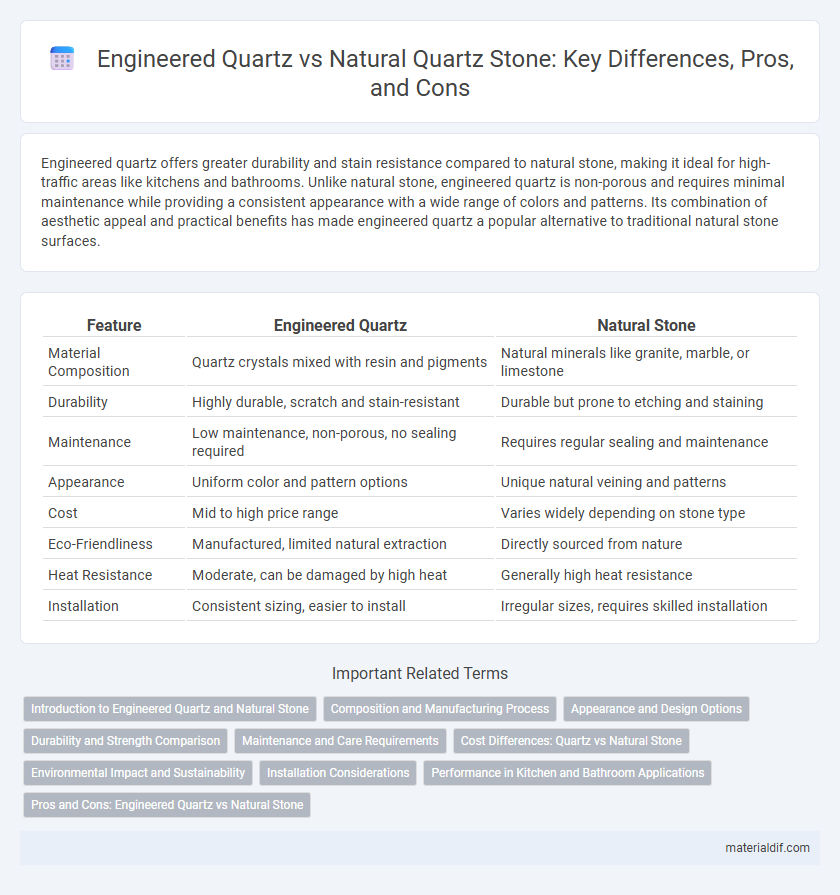

| Feature | Engineered Quartz | Natural Stone |

|---|---|---|

| Material Composition | Quartz crystals mixed with resin and pigments | Natural minerals like granite, marble, or limestone |

| Durability | Highly durable, scratch and stain-resistant | Durable but prone to etching and staining |

| Maintenance | Low maintenance, non-porous, no sealing required | Requires regular sealing and maintenance |

| Appearance | Uniform color and pattern options | Unique natural veining and patterns |

| Cost | Mid to high price range | Varies widely depending on stone type |

| Eco-Friendliness | Manufactured, limited natural extraction | Directly sourced from nature |

| Heat Resistance | Moderate, can be damaged by high heat | Generally high heat resistance |

| Installation | Consistent sizing, easier to install | Irregular sizes, requires skilled installation |

Introduction to Engineered Quartz and Natural Stone

Engineered quartz is a manufactured surface composed of approximately 90% natural quartz crystals combined with resins and pigments, offering enhanced durability and design consistency compared to natural stone. Natural stone, including granite, marble, and travertine, is quarried directly from the earth, showcasing unique veining and color variations that reflect its geological origins. Both materials are popular choices for countertops and surfaces, with engineered quartz providing low maintenance and superior resistance to stains and scratches.

Composition and Manufacturing Process

Engineered quartz consists of approximately 90-95% natural quartz crystals combined with resin binders and pigments, creating a non-porous, uniform surface. Unlike natural stone, which is quarried and cut from solid slabs, engineered quartz is manufactured through a rigorous process involving grinding, mixing, molding, and curing under extreme heat and pressure to enhance durability and consistency. This controlled production results in increased resistance to stains, scratches, and impacts compared to the porous, variable composition of natural stone such as granite or marble.

Appearance and Design Options

Engineered quartz offers a consistent and customizable appearance with a wide range of colors, patterns, and finishes tailored to modern design trends, whereas natural stone such as marble or granite features unique, one-of-a-kind veining and coloration formed by natural processes. The non-porous surface of engineered quartz allows for sleek, uniform designs that can mimic the look of natural stone while providing increased durability and stain resistance. Designers favor engineered quartz for its versatility and ability to maintain vibrant aesthetics over time, compared to the variable appearance and maintenance needs of natural stone surfaces.

Durability and Strength Comparison

Engineered quartz exhibits higher durability and consistent strength due to its composition of approximately 90% quartz crystals combined with resin binders, making it more resistant to chips, cracks, and stains than natural stone. Natural stone such as granite or marble offers variable strength depending on the geological formation but generally requires sealing to prevent damage from moisture and acids. The engineered quartz's non-porous surface enhances its resilience and maintenance ease, positioning it as a superior choice for high-traffic areas and heavy use.

Maintenance and Care Requirements

Engineered quartz offers low maintenance with its non-porous surface resisting stains, scratches, and bacteria, requiring only regular wiping with mild soap and water. Natural stone such as granite or marble demands more care, including periodic sealing to prevent staining and damage from acidic substances. The durability of engineered quartz reduces the need for specialized cleaning products, making it more convenient for daily use compared to natural stone surfaces.

Cost Differences: Quartz vs Natural Stone

Engineered quartz typically costs between $50 and $150 per square foot, offering a more affordable option compared to natural stone, which can range from $70 to $250 per square foot depending on the type. Quartz provides consistent pricing due to its manufactured nature, while natural stone prices fluctuate with rarity, quarry location, and quality of each slab. Installation expenses for both materials are similar, but quartz often results in lower overall costs due to reduced maintenance and higher durability.

Environmental Impact and Sustainability

Engineered quartz demonstrates superior environmental sustainability compared to natural stone due to its use of recycled materials and lower quarrying impact. Manufacturing processes for engineered quartz consume less water and energy while reducing landfill waste through efficient production methods. Natural stone quarrying often leads to habitat disruption and higher carbon emissions, making engineered quartz a more eco-friendly choice for sustainable building projects.

Installation Considerations

Engineered quartz offers greater installation flexibility due to its uniformity, reducing the risk of cracks or chips compared to natural stone. Unlike natural stone, quartz slabs come in consistent sizes and thicknesses, simplifying fitting and alignment during countertop installation. The non-porous surface of engineered quartz also eliminates the need for sealing, streamlining maintenance post-installation.

Performance in Kitchen and Bathroom Applications

Engineered quartz offers superior durability and resistance to stains, scratches, and heat compared to natural stone, making it ideal for high-traffic kitchen and bathroom surfaces. Its non-porous composition prevents bacterial growth and eliminates the need for sealing, enhancing hygiene and reducing maintenance. Natural stone, while aesthetically unique, requires regular sealing and is more prone to chipping and staining, which can affect long-term performance in moisture-rich environments.

Pros and Cons: Engineered Quartz vs Natural Stone

Engineered quartz offers consistent color and pattern, low maintenance due to its non-porous surface, and higher resistance to stains and scratches compared to natural stone. Natural stone, such as granite or marble, provides unique, authentic textures and is heat resistant but often requires regular sealing and is more prone to etching and chipping. Cost-wise, engineered quartz is typically more affordable and durable, while natural stone carries a premium price and can vary greatly in quality and longevity.

Engineered Quartz vs Natural Stone Infographic

materialdif.com

materialdif.com