Quartz powder consists of fine, finely ground particles ideal for applications requiring smooth finishes, such as in ceramics and coatings. Quartz grit features larger, coarser granules primarily used for abrasive blasting and filtration media. The choice between quartz powder and quartz grit depends on the desired texture and functional properties in industrial processes.

Table of Comparison

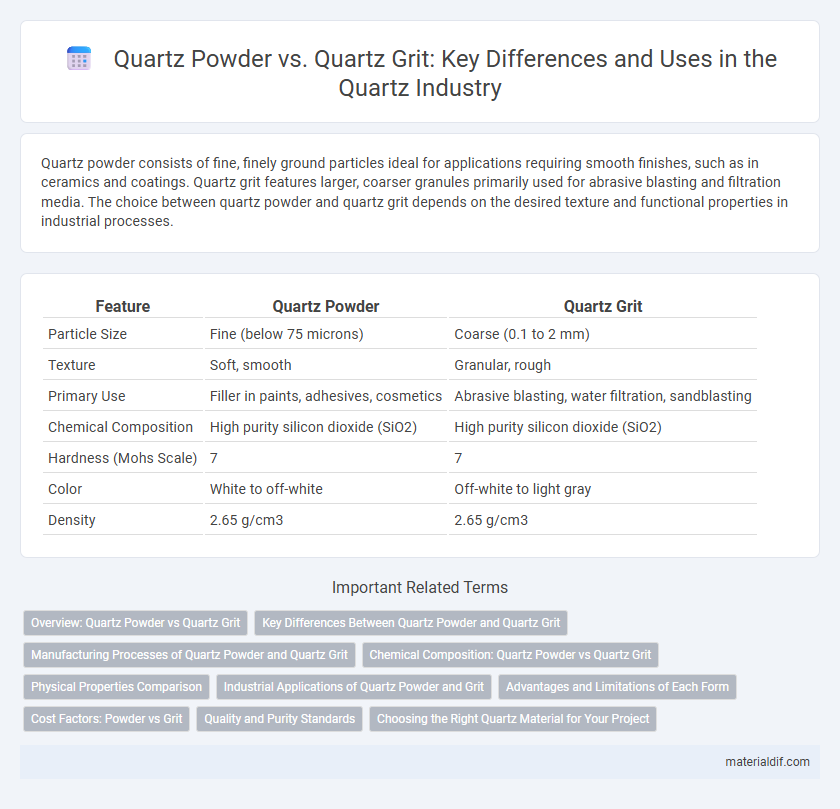

| Feature | Quartz Powder | Quartz Grit |

|---|---|---|

| Particle Size | Fine (below 75 microns) | Coarse (0.1 to 2 mm) |

| Texture | Soft, smooth | Granular, rough |

| Primary Use | Filler in paints, adhesives, cosmetics | Abrasive blasting, water filtration, sandblasting |

| Chemical Composition | High purity silicon dioxide (SiO2) | High purity silicon dioxide (SiO2) |

| Hardness (Mohs Scale) | 7 | 7 |

| Color | White to off-white | Off-white to light gray |

| Density | 2.65 g/cm3 | 2.65 g/cm3 |

Overview: Quartz Powder vs Quartz Grit

Quartz powder consists of finely ground quartz particles typically less than 75 microns in size, making it ideal for use in silica-based products, industrial applications, and as a filler in paints and plastics. Quartz grit refers to coarser granules, generally ranging from 150 to 600 microns, commonly used in abrasive blasting, filtration, and as a base material in construction. The key difference lies in particle size and application, with quartz powder favored for smooth finishes and chemical processing, while quartz grit is preferred for durability and mechanical abrasion.

Key Differences Between Quartz Powder and Quartz Grit

Quartz powder consists of finely ground quartz particles measuring less than 75 microns, offering a smooth texture ideal for applications requiring high precision such as ceramics and electronics. In contrast, quartz grit features coarser particles typically ranging from 0.1 to 2 mm, providing superior abrasion resistance and durability for use in sandblasting, filtration, and industrial grinding. The key difference lies in particle size and surface texture, which directly influence their specific industrial functions and performance characteristics.

Manufacturing Processes of Quartz Powder and Quartz Grit

Quartz powder is produced through a meticulous grinding and milling process that reduces quartz crystals into fine, uniform particles essential for high-precision applications like electronics and coatings. Quartz grit, on the other hand, is manufactured by crushing and sieving quartz rock into coarser granules used predominantly in abrasive blasting and filtration media. Both processes require controlled crushing, washing, and drying steps to achieve specific particle size distributions and purity levels vital for their respective industrial uses.

Chemical Composition: Quartz Powder vs Quartz Grit

Quartz powder and quartz grit both primarily consist of silicon dioxide (SiO2), but the difference lies in their particle size and purity levels affecting chemical composition in practical terms. Quartz powder has a finer particle size, often containing fewer impurities and higher purity SiO2, making it suitable for applications requiring chemical consistency like electronics and ceramics. Quartz grit features coarser particles with potential trace minerals and impurities due to less processing, impacting its use in abrasive media and filtration where high purity is less critical.

Physical Properties Comparison

Quartz powder consists of finely ground particles typically less than 75 microns, offering a smooth texture and high surface area ideal for coatings and polishing applications. Quartz grit features coarser grains ranging from 0.2 to 2 millimeters, providing greater abrasive strength and durability used primarily in sandblasting and filtration media. The distinct particle size distribution between quartz powder and quartz grit directly influences their compressive strength, porosity, and flow characteristics in industrial processes.

Industrial Applications of Quartz Powder and Grit

Quartz powder, characterized by its fine particle size, is extensively used in the production of glass, ceramics, and electronic components due to its high purity and uniform texture. Quartz grit, with its coarser granules, finds industrial applications in abrasive blasting, sandpaper manufacturing, and as a filler in construction materials to enhance durability. Both forms leverage quartz's hardness and chemical stability, optimizing performance in industries such as metallurgy, foundry, and refractory materials.

Advantages and Limitations of Each Form

Quartz powder offers superior uniformity and fine particle size, making it ideal for applications requiring smooth finishes and precise mixtures, such as in ceramics and coatings, but it may pose inhalation risks without proper handling. Quartz grit provides a coarser texture beneficial for abrasive cleaning, sandblasting, and filtration, delivering effective surface roughening and filtration capacity, though it lacks the smoothness required for fine finishing tasks. Selection depends on specific industrial needs, balancing particle size advantages against safety and application requirements.

Cost Factors: Powder vs Grit

Quartz powder typically incurs higher production costs due to the extensive grinding and milling processes required to achieve its fine particle size, resulting in increased energy consumption and equipment wear. Quartz grit, characterized by coarser granules, generally demands less processing, making it more cost-effective for large-scale industrial applications. The pricing disparity between quartz powder and grit often reflects these differences in processing intensity, impacting purchase decisions based on budget and application needs.

Quality and Purity Standards

Quartz powder features ultra-fine particles with consistently high purity levels, typically exceeding 99.9%, making it ideal for applications demanding strict quality control such as electronics and optical industries. Quartz grit consists of coarser granules and may contain trace impurities, requiring rigorous quality standards to ensure suitability for industrial uses like metal casting and abrasive blasting. Both forms undergo stringent purification processes to meet industry-specific quality and purity standards, ensuring optimal performance and reliability.

Choosing the Right Quartz Material for Your Project

Quartz powder offers a fine particle size ideal for precision applications such as cosmetics, ceramics, and fillers, enhancing smoothness and uniformity in final products. Quartz grit, consisting of coarser granules, is preferred in abrasive blasting, filtration, and landscaping due to its durability and effective particle separation. Selecting the right quartz material depends on the project's surface texture requirements, with powder optimizing fine finish and grit ensuring robust structural applications.

Quartz Powder vs Quartz Grit Infographic

materialdif.com

materialdif.com