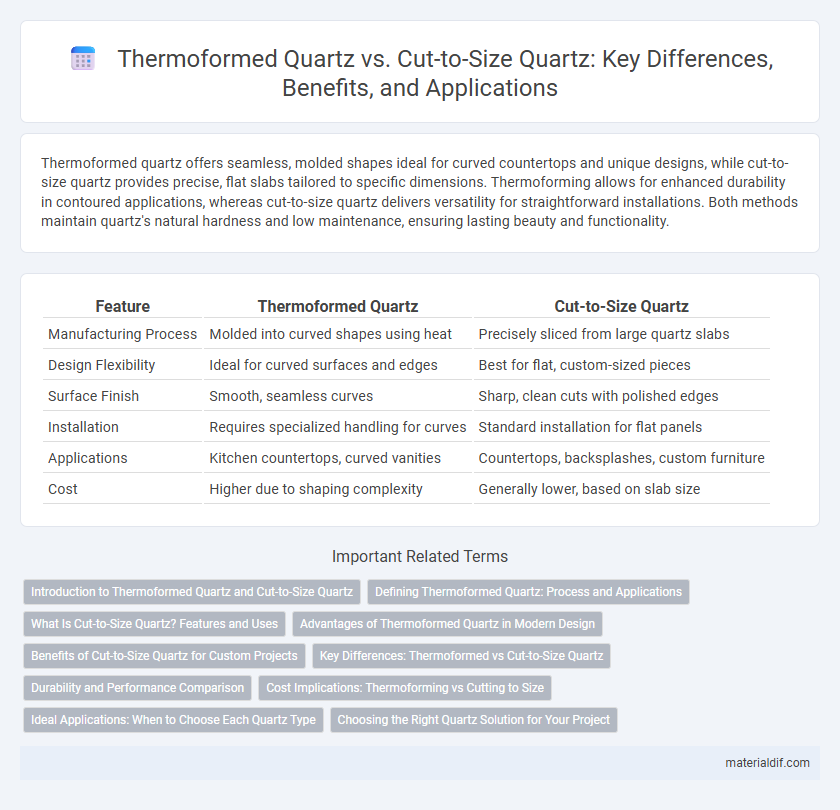

Thermoformed quartz offers seamless, molded shapes ideal for curved countertops and unique designs, while cut-to-size quartz provides precise, flat slabs tailored to specific dimensions. Thermoforming allows for enhanced durability in contoured applications, whereas cut-to-size quartz delivers versatility for straightforward installations. Both methods maintain quartz's natural hardness and low maintenance, ensuring lasting beauty and functionality.

Table of Comparison

| Feature | Thermoformed Quartz | Cut-to-Size Quartz |

|---|---|---|

| Manufacturing Process | Molded into curved shapes using heat | Precisely sliced from large quartz slabs |

| Design Flexibility | Ideal for curved surfaces and edges | Best for flat, custom-sized pieces |

| Surface Finish | Smooth, seamless curves | Sharp, clean cuts with polished edges |

| Installation | Requires specialized handling for curves | Standard installation for flat panels |

| Applications | Kitchen countertops, curved vanities | Countertops, backsplashes, custom furniture |

| Cost | Higher due to shaping complexity | Generally lower, based on slab size |

Introduction to Thermoformed Quartz and Cut-to-Size Quartz

Thermoformed quartz is engineered by heating and molding quartz slabs into curved shapes, allowing for seamless designs and integrated edges commonly used in kitchen countertops and bathroom vanities. Cut-to-size quartz involves precision cutting slabs into specific dimensions with straight edges, offering customization for flat surface installations and easier fabrication. Both methods utilize engineered quartz composed of approximately 90-95% natural quartz combined with resins and pigments, ensuring durability, stain resistance, and low maintenance.

Defining Thermoformed Quartz: Process and Applications

Thermoformed quartz involves heating engineered quartz slabs until pliable, then molding them into curved shapes for seamless countertops and unique architectural features. This process enhances design flexibility without compromising quartz's durability and resistance to stains or scratches. Common applications include curved kitchen islands, bathroom vanity tops, and custom wall claddings where traditional cut-to-size quartz cannot achieve continuous curves.

What Is Cut-to-Size Quartz? Features and Uses

Cut-to-size quartz refers to engineered quartz slabs precisely cut to specific dimensions, offering versatility for various applications such as countertops, backsplashes, and wall cladding. Its features include custom sizing, minimal waste, and ease of installation, making it ideal for tailored design projects in kitchens, bathrooms, and commercial spaces. The material retains quartz's durability, non-porous surface, and resistance to stains and scratches, ensuring both functionality and aesthetic appeal.

Advantages of Thermoformed Quartz in Modern Design

Thermoformed quartz offers superior versatility in modern design by enabling complex shapes and seamless curves that cut-to-size quartz cannot easily achieve. This process enhances durability and reduces installation time due to fewer joints and cuts, resulting in sleek, contemporary aesthetics. Its ability to conform to custom molds makes thermoformed quartz ideal for innovative kitchen islands, curved countertops, and integrated backsplashes.

Benefits of Cut-to-Size Quartz for Custom Projects

Cut-to-size quartz offers precise dimensions tailored to specific project requirements, minimizing waste and installation time. This customization ensures a perfect fit for unique design elements, enhancing aesthetic appeal and functionality. Compared to thermoformed quartz, cut-to-size quartz provides greater design flexibility and cost efficiency for bespoke applications.

Key Differences: Thermoformed vs Cut-to-Size Quartz

Thermoformed quartz undergoes a heating process that shapes the material into curved forms, ideal for countertops with seamless edges and complex designs, while cut-to-size quartz is precisely cut from large slabs to specific dimensions, emphasizing straight edges and flat surfaces. Thermoforming allows for enhanced design flexibility and reduced visible seams, contrasting with the typically lower cost and faster production time of cut-to-size quartz. Selection between these methods depends on project complexity, budget constraints, and desired visual aesthetics.

Durability and Performance Comparison

Thermoformed quartz offers enhanced durability due to its seamless construction, reducing potential weak points compared to cut-to-size quartz, which involves joining multiple pieces. Cut-to-size quartz provides precise customization and easier installation but may have increased vulnerability to cracks along seams. Overall, thermoformed quartz delivers superior performance in high-impact and high-moisture environments, making it ideal for heavy-use applications.

Cost Implications: Thermoforming vs Cutting to Size

Thermoformed quartz typically incurs higher upfront costs due to specialized molds and heating processes, but offers reduced labor expenses and less material waste compared to cut-to-size quartz. Cut-to-size quartz involves lower initial tooling costs but may lead to increased labor and material waste, impacting overall budgets when producing complex shapes. Cost efficiency depends on project scale and design complexity, with thermoforming favored for intricate, large-volume orders.

Ideal Applications: When to Choose Each Quartz Type

Thermoformed quartz is ideal for curved surfaces and seamless designs, making it perfect for custom countertops, backsplashes, and bathroom vanities that require molded edges or complex shapes. Cut-to-size quartz suits straightforward applications such as flat kitchen countertops, wall cladding, and flooring, providing precise dimensions without the need for shaping or bending. Choosing thermoformed quartz is best when durability and aesthetic flow on irregular surfaces are priorities, while cut-to-size quartz excels in projects demanding exact fits and simpler installation.

Choosing the Right Quartz Solution for Your Project

Thermoformed quartz offers seamless, curved designs ideal for modern kitchens and bathrooms, providing durability and a smooth finish with fewer joints, enhancing both aesthetics and hygiene. Cut-to-size quartz slabs provide maximum customization with precise dimensions, suitable for projects requiring tailored surfaces or intricate details, ensuring optimal material usage and lower waste. Selecting the right quartz solution depends on the project's design requirements, budget constraints, and desired installation complexity, balancing form and function for long-lasting results.

Thermoformed Quartz vs Cut-to-Size Quartz Infographic

materialdif.com

materialdif.com