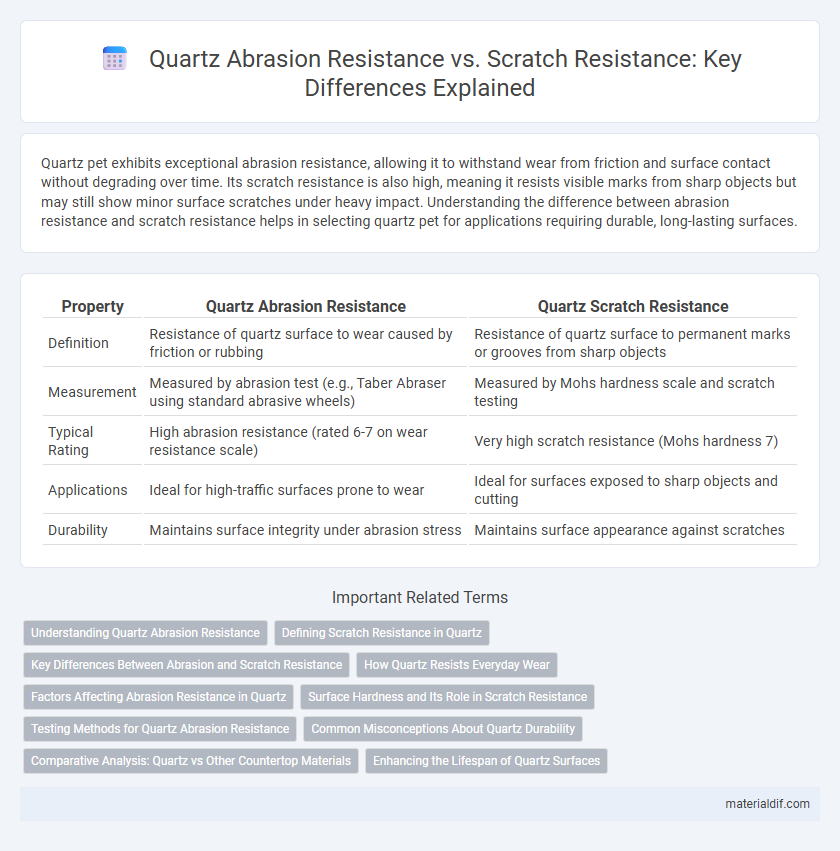

Quartz pet exhibits exceptional abrasion resistance, allowing it to withstand wear from friction and surface contact without degrading over time. Its scratch resistance is also high, meaning it resists visible marks from sharp objects but may still show minor surface scratches under heavy impact. Understanding the difference between abrasion resistance and scratch resistance helps in selecting quartz pet for applications requiring durable, long-lasting surfaces.

Table of Comparison

| Property | Quartz Abrasion Resistance | Quartz Scratch Resistance |

|---|---|---|

| Definition | Resistance of quartz surface to wear caused by friction or rubbing | Resistance of quartz surface to permanent marks or grooves from sharp objects |

| Measurement | Measured by abrasion test (e.g., Taber Abraser using standard abrasive wheels) | Measured by Mohs hardness scale and scratch testing |

| Typical Rating | High abrasion resistance (rated 6-7 on wear resistance scale) | Very high scratch resistance (Mohs hardness 7) |

| Applications | Ideal for high-traffic surfaces prone to wear | Ideal for surfaces exposed to sharp objects and cutting |

| Durability | Maintains surface integrity under abrasion stress | Maintains surface appearance against scratches |

Understanding Quartz Abrasion Resistance

Quartz abrasion resistance refers to the material's ability to withstand wear from friction and rubbing, which is critical in high-traffic applications like countertops and flooring. This property is primarily influenced by quartz's hardness on the Mohs scale, typically around 7, making it highly resistant to surface wear and maintaining its appearance over time. Understanding quartz abrasion resistance helps differentiate it from scratch resistance, which specifically relates to how easily the surface can be marked by sharp objects.

Defining Scratch Resistance in Quartz

Scratch resistance in quartz refers to the material's ability to withstand surface damage caused by sharp or abrasive objects without leaving visible marks or grooves. This property is primarily determined by quartz's hardness on the Mohs scale, which typically ranges around 7, making it highly resistant to scratches from everyday items like knives or keys. Understanding scratch resistance is crucial for evaluating quartz surfaces' durability and maintaining their aesthetic appeal over time.

Key Differences Between Abrasion and Scratch Resistance

Quartz abrasion resistance measures the material's ability to withstand wear from rubbing or friction over time, making it ideal for surfaces exposed to constant use and cleaning. Scratch resistance specifically refers to quartz's capacity to resist surface damage caused by sharp or pointed objects, critical for maintaining the stone's aesthetic integrity. While abrasion resistance evaluates durability against gradual erosion, scratch resistance focuses on preventing visible marks from localized contact.

How Quartz Resists Everyday Wear

Quartz exhibits exceptional abrasion resistance due to its hardness rating of 7 on the Mohs scale, which allows it to withstand everyday wear from grinding and scraping. Its tightly packed silicon dioxide crystals create a dense surface that limits damage from minor scratches and impacts. This combination of abrasion and scratch resistance ensures quartz countertops maintain their smooth, polished finish even under frequent use.

Factors Affecting Abrasion Resistance in Quartz

Quartz abrasion resistance depends largely on factors such as the hardness of the quartz particles, the quality of the resin binder, and the density of the compacted surface. Variations in particle size distribution and the degree of curing can significantly influence the surface's ability to resist wear caused by friction. Environmental conditions like exposure to UV light and moisture also play crucial roles in maintaining the integrity of quartz surfaces against abrasion.

Surface Hardness and Its Role in Scratch Resistance

Quartz's high surface hardness, typically measured around 7 on the Mohs scale, plays a critical role in its scratch resistance by making it less susceptible to damage from everyday materials. Abrasion resistance refers to the material's ability to withstand wear from friction, while scratch resistance specifically denotes how well it resists surface marks from sharp objects. This inherent hardness of quartz allows it to maintain a polished, durable appearance even under frequent use, distinguishing it from softer countertop materials.

Testing Methods for Quartz Abrasion Resistance

Quartz abrasion resistance testing typically involves standardized methods such as the Taber abrasion test, where a rotating abrasive wheel measures material wear over time. Scratch resistance, on the other hand, is often evaluated using the Mohs hardness test, which assesses quartz's ability to resist surface indentation or scratches from mineral points of known hardness. These testing methodologies provide critical data distinguishing quartz's durability in both wear resistance and surface scratch prevention applications.

Common Misconceptions About Quartz Durability

Quartz is often mistaken for being impervious to damage, but its abrasion resistance and scratch resistance differ significantly. Quartz surfaces exhibit high abrasion resistance due to their engineered composition, yet they can still be scratched by materials harder than quartz particles, such as diamond or certain metals. Misunderstandings arise when users assume quartz countertops are completely scratch-proof, leading to improper care that can diminish their long-term durability.

Comparative Analysis: Quartz vs Other Countertop Materials

Quartz exhibits superior abrasion resistance compared to natural stones like granite and marble, maintaining its polished surface under daily wear and tear. Its engineered composition offers higher scratch resistance than softer materials such as laminate and solid surface countertops. This combination of durability and resilience makes quartz a preferred choice for high-traffic kitchen environments.

Enhancing the Lifespan of Quartz Surfaces

Quartz abrasion resistance directly impacts the durability of quartz surfaces by preventing surface wear caused by friction and repeated contact with rough materials. Scratch resistance contributes to maintaining the aesthetic appeal by reducing visible marks from sharp objects, essential for preserving the surface's polished finish. Combining high abrasion and scratch resistance significantly enhances the lifespan of quartz countertops and tiles, ensuring long-term performance in kitchens and commercial environments.

Quartz Abrasion Resistance vs Scratch Resistance Infographic

materialdif.com

materialdif.com