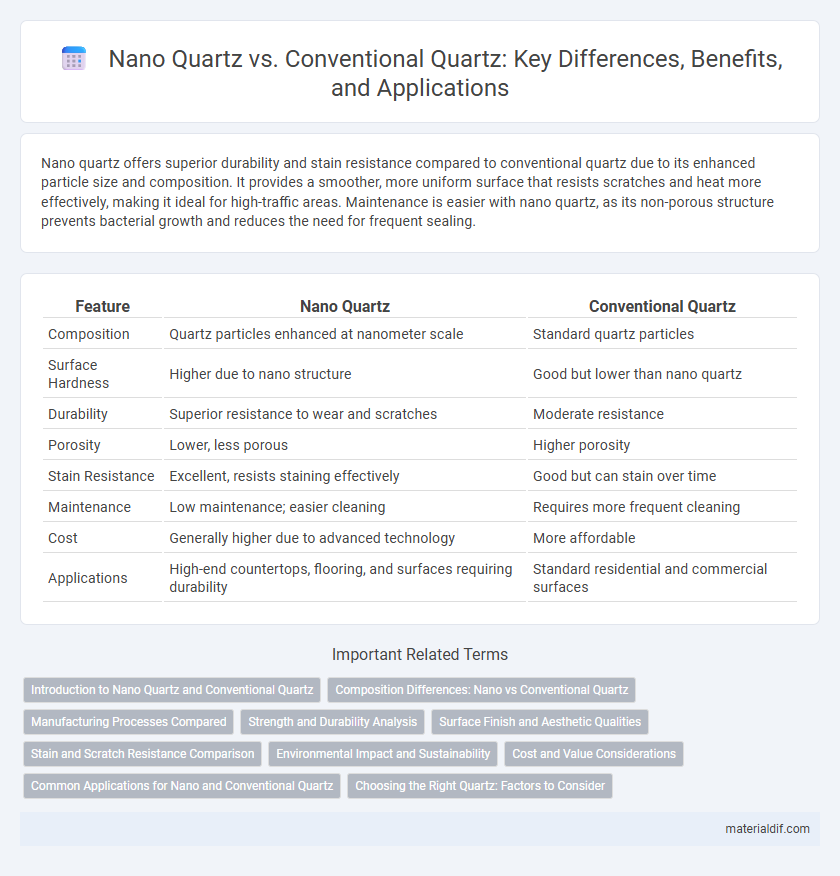

Nano quartz offers superior durability and stain resistance compared to conventional quartz due to its enhanced particle size and composition. It provides a smoother, more uniform surface that resists scratches and heat more effectively, making it ideal for high-traffic areas. Maintenance is easier with nano quartz, as its non-porous structure prevents bacterial growth and reduces the need for frequent sealing.

Table of Comparison

| Feature | Nano Quartz | Conventional Quartz |

|---|---|---|

| Composition | Quartz particles enhanced at nanometer scale | Standard quartz particles |

| Surface Hardness | Higher due to nano structure | Good but lower than nano quartz |

| Durability | Superior resistance to wear and scratches | Moderate resistance |

| Porosity | Lower, less porous | Higher porosity |

| Stain Resistance | Excellent, resists staining effectively | Good but can stain over time |

| Maintenance | Low maintenance; easier cleaning | Requires more frequent cleaning |

| Cost | Generally higher due to advanced technology | More affordable |

| Applications | High-end countertops, flooring, and surfaces requiring durability | Standard residential and commercial surfaces |

Introduction to Nano Quartz and Conventional Quartz

Nano Quartz incorporates nanoparticles into the quartz matrix, enhancing hardness and resistance to scratches compared to Conventional Quartz. Conventional Quartz consists mainly of natural quartz crystals combined with resin and pigments, offering durability but less advanced surface protection. The nanotechnology in Nano Quartz provides superior structural integrity and improved anti-bacterial properties, setting it apart from traditional quartz surfaces.

Composition Differences: Nano vs Conventional Quartz

Nano quartz particles exhibit a significantly smaller grain size compared to conventional quartz, leading to enhanced surface area and reactivity. The nano-scale quartz includes particles typically under 100 nanometers, which differ in crystal structure uniformity and surface chemistry from the larger, micrometer-sized grains found in conventional quartz. These compositional differences affect physical properties such as hardness, transparency, and chemical stability, making nano quartz more suitable for high-precision applications and advanced material composites.

Manufacturing Processes Compared

Nano quartz production utilizes advanced nanotechnology to create finer, more uniform particles, resulting in enhanced surface area and mechanical properties compared to conventional quartz, which relies on standard milling and grinding techniques. The manufacturing process of nano quartz involves controlled synthesis methods such as sol-gel or chemical vapor deposition to achieve consistent particle size and purity. Conventional quartz processing typically includes crushing and thermal treatment but lacks the precision and functional enhancements found in nano quartz production, leading to differences in durability and application performance.

Strength and Durability Analysis

Nano quartz exhibits superior strength and durability compared to conventional quartz due to its finer particle size and enhanced uniformity in microstructure. The increased surface area of nano quartz particles contributes to higher resistance against wear, abrasion, and impact forces, making it ideal for demanding industrial applications. Empirical studies reveal that nano quartz composites maintain structural integrity under extreme mechanical stress, outperforming traditional quartz materials by significant margins.

Surface Finish and Aesthetic Qualities

Nano quartz offers a superior surface finish compared to conventional quartz due to its finer particle size, resulting in a smoother, more reflective surface with enhanced uniformity. The advanced nano-scale structure improves aesthetic qualities by providing richer color depth and increased resistance to staining and etching, maintaining its polished look over time. Conventional quartz, while durable, typically exhibits a coarser texture and less vibrant color consistency, impacting its long-term visual appeal.

Stain and Scratch Resistance Comparison

Nano quartz surfaces demonstrate superior stain and scratch resistance compared to conventional quartz due to their enhanced particle size uniformity and advanced resin bonding technology. The nano-scale particles create a denser, less porous surface that significantly reduces the absorption of liquids and minimizes abrasion marks. Independent laboratory tests confirm Nano Quartz outperforms traditional quartz in resisting common household stains and scratches, extending the durability and aesthetic longevity of countertops.

Environmental Impact and Sustainability

Nano Quartz exhibits significantly lower environmental impact compared to conventional quartz due to its reduced raw material consumption and enhanced durability, which extends product lifespan and decreases waste generation. Its sustainable manufacturing process utilizes lower energy inputs and minimizes harmful emissions, aligning with eco-friendly industry standards. The nanotechnology integration also promotes recyclability, making Nano Quartz a more sustainable choice for environmentally conscious construction and design projects.

Cost and Value Considerations

Nano quartz offers a more cost-effective alternative to conventional quartz, often priced lower due to advanced manufacturing efficiencies and smaller particle size requirements. While conventional quartz provides proven durability and aesthetic appeal, nano quartz enhances surface hardness and scratch resistance, delivering higher long-term value despite initial price differences. Cost considerations should balance upfront expenses with durability benefits, where nano quartz's enhanced performance can reduce maintenance and replacement costs over time.

Common Applications for Nano and Conventional Quartz

Nano Quartz is widely used in high-precision applications such as electronics, medical devices, and advanced optics due to its enhanced purity and uniform particle size. Conventional Quartz finds extensive use in construction materials, glass manufacturing, and ceramics, leveraging its robust mechanical properties and cost-effectiveness. Both forms serve critical roles in industrial processes, with Nano Quartz catering to technologically demanding fields and Conventional Quartz supporting traditional manufacturing sectors.

Choosing the Right Quartz: Factors to Consider

When choosing the right quartz, consider the durability and abrasion resistance of nano quartz, which offers enhanced strength due to its finer particle size compared to conventional quartz. Evaluate the application environment, as nano quartz provides superior stain resistance and UV stability, making it ideal for high-traffic or outdoor areas. Cost and maintenance requirements are also critical factors, with nano quartz generally requiring less upkeep and delivering longer-lasting aesthetic appeal.

Nano Quartz vs Conventional Quartz Infographic

materialdif.com

materialdif.com