Quartz offers superior durability and low maintenance compared to concrete, making it ideal for countertops and high-traffic surfaces. Its non-porous nature resists stains and bacteria better than concrete, which often requires sealing and can crack over time. Quartz also provides a more consistent appearance with a wide range of colors and patterns, while concrete tends to have a rougher, more industrial look.

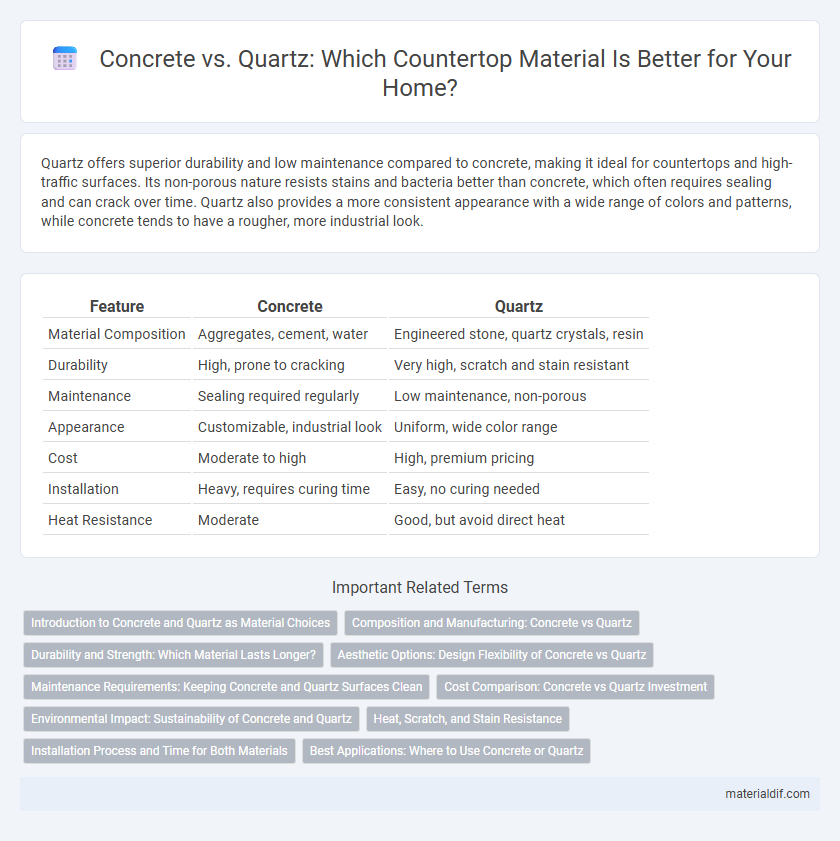

Table of Comparison

| Feature | Concrete | Quartz |

|---|---|---|

| Material Composition | Aggregates, cement, water | Engineered stone, quartz crystals, resin |

| Durability | High, prone to cracking | Very high, scratch and stain resistant |

| Maintenance | Sealing required regularly | Low maintenance, non-porous |

| Appearance | Customizable, industrial look | Uniform, wide color range |

| Cost | Moderate to high | High, premium pricing |

| Installation | Heavy, requires curing time | Easy, no curing needed |

| Heat Resistance | Moderate | Good, but avoid direct heat |

Introduction to Concrete and Quartz as Material Choices

Concrete, a composite material consisting of cement, water, and aggregates, is widely used for its durability, versatility, and cost-effectiveness in construction and flooring. Quartz, an engineered stone made from natural quartz crystals combined with resins and pigments, offers superior hardness, non-porosity, and aesthetic appeal ideal for countertops and decorative surfaces. Comparing concrete and quartz involves assessing factors such as maintenance requirements, design options, and long-term performance in various applications.

Composition and Manufacturing: Concrete vs Quartz

Concrete is composed primarily of cement, water, sand, and aggregate materials such as gravel or crushed stone, cured through a chemical hydration process that hardens over time. Quartz surfaces are engineered from natural quartz crystals combined with resin binders and pigments, then subjected to high pressure and heat for durability and consistency. The manufacturing of quartz emphasizes precision and uniformity, while concrete focuses on a natural, variable texture influenced by aggregate size and curing conditions.

Durability and Strength: Which Material Lasts Longer?

Quartz surfaces offer superior durability due to their engineered composition, combining natural quartz crystals with resins for enhanced strength and resistance to scratches, stains, and impacts. Concrete, while strong and able to bear heavy loads, tends to be more porous and susceptible to cracking, chipping, and weathering over time without proper sealing and maintenance. The longevity of quartz surpasses concrete in residential and commercial environments where consistent durability and low maintenance are critical.

Aesthetic Options: Design Flexibility of Concrete vs Quartz

Quartz offers a wider range of aesthetic options compared to concrete, with engineered surfaces available in an extensive palette of colors, patterns, and textures that mimic natural stones like marble and granite. Concrete provides customizable design flexibility through pigmentation, staining, and stamping but often requires additional sealants and finishes to achieve a polished look. The non-porous nature of quartz ensures consistent appearance and durability, making it ideal for sleek, contemporary design projects.

Maintenance Requirements: Keeping Concrete and Quartz Surfaces Clean

Quartz surfaces require minimal maintenance due to their non-porous nature, resisting stains and bacterial growth without the need for sealing. Concrete surfaces demand regular sealing and more frequent cleaning to prevent staining and surface degradation, especially in high-traffic areas. Proper cleaning of quartz involves mild soap and water, while concrete surfaces often need specialized cleaners to maintain durability and appearance.

Cost Comparison: Concrete vs Quartz Investment

Quartz countertops generally have a higher upfront cost compared to concrete, typically ranging from $50 to $150 per square foot, whereas concrete surfaces usually cost between $65 and $135 per square foot. The investment in quartz offers greater durability and lower maintenance expenses over time due to its non-porous, stain-resistant properties, reducing potential repair and sealing costs associated with concrete. Considering long-term value, quartz often presents a more cost-effective option despite the initial price difference, especially in high-traffic or moisture-prone areas.

Environmental Impact: Sustainability of Concrete and Quartz

Quartz countertops have a lower environmental impact compared to concrete due to their longevity and less frequent need for replacement, reducing resource consumption over time. Concrete production generates significant CO2 emissions from cement manufacturing, whereas engineered quartz uses recycled materials and natural quartz, promoting sustainability. Choosing quartz contributes to eco-friendly building practices by minimizing waste and energy usage during production.

Heat, Scratch, and Stain Resistance

Quartz surfaces exhibit superior heat resistance compared to concrete, withstanding temperatures up to 300degF without damage, whereas concrete can crack under extreme heat exposure. Quartz's non-porous composition provides excellent scratch resistance, making it more durable against daily wear compared to the more porous and softer nature of concrete. Additionally, quartz offers greater stain resistance due to its engineered surface, which prevents absorption of liquids, unlike concrete that requires sealing to protect against permanent staining.

Installation Process and Time for Both Materials

Quartz countertops typically offer a faster installation process compared to concrete due to their pre-manufactured slabs that require minimal on-site fabrication. Concrete countertops demand extensive curing time, often taking up to several days or weeks, whereas quartz can be installed within a few hours after delivery. The precision and consistency of quartz slabs streamline the workflow, reducing overall labor and project duration.

Best Applications: Where to Use Concrete or Quartz

Quartz surfaces excel in kitchens and bathrooms due to their durability, non-porous nature, and resistance to stains and scratches, making them ideal for countertops and backsplashes. Concrete proves best suited for outdoor settings, patios, and industrial-style interiors because of its strength, customizable finishes, and weather resistance. Both materials perform well in commercial spaces, but quartz is preferred for high-traffic indoor areas requiring low maintenance, while concrete supports heavy use and unique design aesthetics.

Concrete vs Quartz Infographic

materialdif.com

materialdif.com